Description

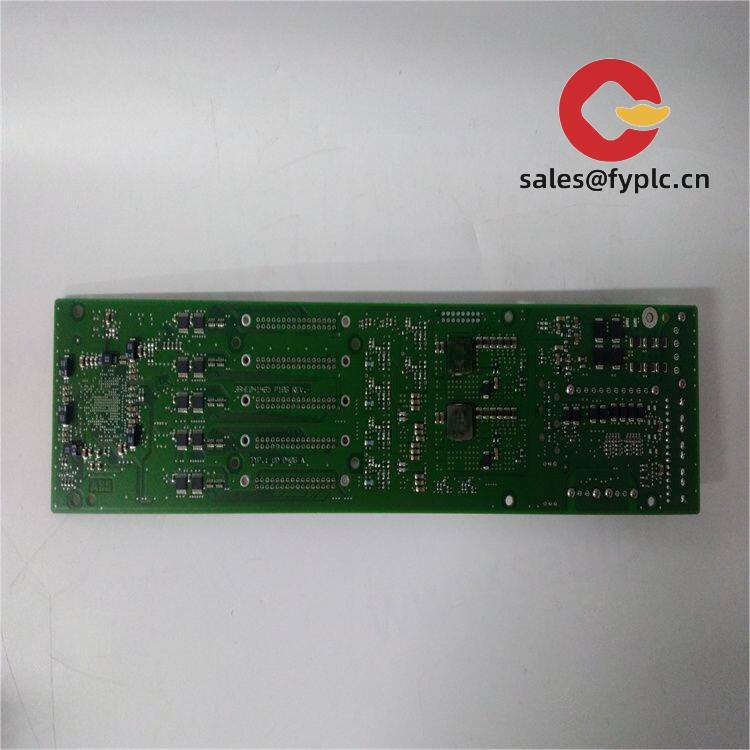

ABB UCD240A101 (3BHE022287R0101) – Drive Control Board for ABB Medium-Voltage Drive Systems

The ABB UCD240A101, part number 3BHE022287R0101, is a control board module typically used in ABB medium-voltage drive platforms. From my experience, this board sits at the heart of the drive’s control section—managing high-speed signaling to power stacks, coordinating protection logic, and maintaining reliable fiber-optic communication within the system. If you’re maintaining ACS-series MV drives (commonly ACS1000/ACS6000 families), this module is often the piece that restores stable operation after intermittent trips or comms errors.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

We typically pre-test boards prior to shipment and pack them in ESD-safe materials with foam reinforcement. You might notice that this reduces installation headaches—less time lost to “DOA” diagnostics on site.

Key Features

- Dedicated ABB drive control logic – Coordinates gating, protection, and interlocks for MV drive sections, helping maintain stable operation under load variations.

- Fiber-optic communication channels – In many cases, the UCD board uses ABB’s fiber-optic links for noise-immune data exchange with power cells and I/O subsystems.

- 24 VDC control supply – Standard control voltage simplifies replacement and on-site testing.

- Backplane/rack integration – Plug-in board design for quick swap, reducing downtime during maintenance.

- Firmware compatibility – Typically supports firmware matched to the target drive; we can help verify revision pairing to avoid nuisance trips.

- Robust protection handling – Monitors conditions and communicates trips/faults upstream to protect the motor and converter hardware.

Technical Specifications

| Brand / Model | ABB UCD240A101 |

| Manufacturer P/N | 3BHE022287R0101 |

| Product Type | Drive control board (plug-in module) |

| Typical Platform Compatibility | ABB medium-voltage drives (commonly ACS1000 / ACS6000 families; check by drive ID/serial) |

| HS Code | 8538.90 (Parts suitable for electrical apparatus) |

| Power Requirements | 24 VDC control supply (typical) |

| Communication Interfaces | Fiber-optic channels for drive communication; backplane interface; service/maintenance port (varies by revision) |

| Signal I/O Types | High-speed sync/control signals; status/diagnostics; interfaces to protection and gating circuitry |

| Installation Method | Rack/backplane plug-in; secured with card guides and fastening points; ESD-safe handling required |

Application Fields

The UCD240A101 appears most often in medium-voltage drive cabinets used in:

- Metals and mining – MV fan/pump drives, mills, conveyors

- Cement and minerals – Kiln fans, ID/FD fans, raw-mill drives

- Oil & gas / petrochem – Compressors and high-power pumping

- Power generation – Boiler feed pumps, auxiliary MV drives

- Marine – Propulsion and large onboard process drives

A maintenance engineer at a cement plant told us this board was the “quiet fix” for sporadic fiber link faults; swapping the UCD cut their nuisance trips to zero for months. That lines up with what we typically see after long thermal cycles.

Advantages & Value

- Reliability – Designed for harsh MV environments with noise-immune fiber comms.

- Compatibility – Matches ABB architecture, minimizing integration risk during replacement.

- Reduced downtime – Plug-in form factor; changeover can be done during a short production window.

- Technical support – We help verify firmware and drive compatibility before shipment, which in many cases prevents commissioning delays.

- Lifecycle support – Guidance on related parts (DDCS fibers, backplane, 24 VDC PSU) if a broader refresh makes sense.

Installation & Maintenance

- Environment – Install in a clean, dry cabinet with proper ventilation; keep ambient within the drive’s specified range.

- ESD safety – Use grounded wrist straps and ESD mats; handle the board by edges only.

- Power – Verify stable 24 VDC control supply; check grounding and shield terminations for fiber and control wiring.

- Wiring – Route fibers with gentle bend radius; avoid tight ties near high dV/dt cables.

- Commissioning – Confirm firmware/revision compatibility, run self-tests, and review diagnostic LEDs/status.

- Routine care – Periodically clean dust with dry air (low pressure), inspect connectors, and review event logs for early signs of degradation.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- Conforms to CE directives for industrial control equipment (typical for ABB drive components)

- RoHS compliance status depends on drive generation; we can confirm by serial

- UL recognition usually at the system/cabinet level for MV drives

- Warranty: 365 days

Related and Supporting Components

- ABB DDCS fiber-optic cables (drive communication)

- Drive backplane/rack hardware for UCD-series boards

- 24 VDC control power supplies and redundancy modules

- Associated I/O and interface boards used in ACS1000/ACS6000 cabinets

If you can share the drive type code and serial, we’ll double-check the UCD240A101 revision against your installed firmware and advise on any accessory parts that tend to age out at the same time. That small step, in many cases, saves a second shutdown.

Reviews

There are no reviews yet.