Description

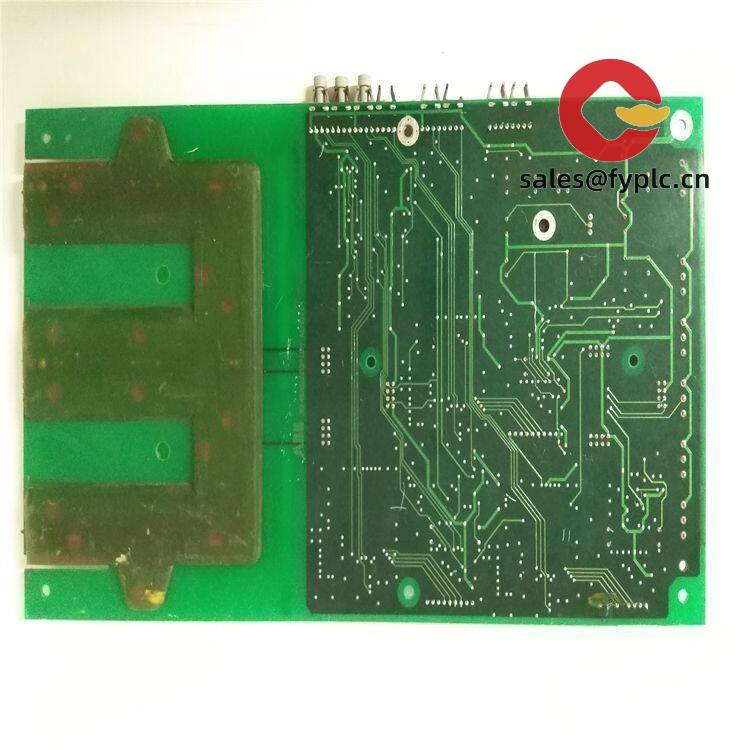

ABB UFC760BE1142 (3BHE004573R1142) – Central Controller Board for UNITROL 5000 Excitation Systems

The ABB UFC760BE1142, part number 3BHE004573R1142, is a core controller board used in ABB UNITROL 5000 excitation systems for synchronous generators and large synchronous motors. From my experience, this is the module that orchestrates closed-loop voltage and reactive power control, coordinates protection functions, and manages communications with I/O and power interface modules. In many cases it’s the go-to spare when you need to recover a downed excitation cabinet quickly and keep a turbine or critical process online.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express Options: fedex, UPS, DHL

- Packaging: ESD-safe, foam-in-box, moisture barrier where required

- Traceability: Serial and revision recorded on the delivery note

Key Features

- Purpose-built for UNITROL 5000: Works as the central control board coordinating excitation control, protection, and diagnostics.

- Deterministic control performance: Real-time control platform designed for fast voltage and reactive power response under grid disturbances.

- Backplane integration: Plugs directly into the UNITROL rack backplane for power, I/O bus and inter-board signaling—no field rewiring.

- Multiple communication paths: Typically supports Ethernet service access and fieldbuses (e.g., CAN) to I/O and peripheral boards.

- Event and fault diagnostics: Detailed status LEDs and onboard diagnostics simplify commissioning and troubleshooting.

- Service-friendly replacement: Front-access connectors and keyed guides make swap-outs straightforward during outages.

Technical Specifications

| Brand / Model | ABB UFC760BE1142 (3BHE004573R1142) |

| Product Type | Controller board for UNITROL 5000 excitation systems |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | 24 V DC nominal via backplane; typical consumption < 10 W |

| Dimensions & Weight | Approx. 6U Eurocard board (about 233 x 160 mm); ~0.4 kg |

| Operating Temperature | 0 to +55 °C (cabinet-dependent) |

| Signal I/O Types | Backplane analog/digital control signals; status via front LEDs; user I/O via system I/O modules |

| Communication Interfaces | Service Ethernet (10/100), CAN bus to I/O modules; fiber/serial links depending on cabinet design |

| Installation Method | Plug-in card for UNITROL 5000 rack/backplane; front-retained with guide rails |

Application Fields

You’ll typically find this board in power generation (hydro, steam, gas) and in heavy industry where synchronous motors need robust excitation—steel mills, paper, cement, mining, and oil & gas utilities. It’s also a common spare at plant maintenance stores because a healthy controller board can bring a trip-latched exciter back within minutes once wiring and settings are verified.

Advantages & Value

- Reduced downtime: Drop-in replacement in the UNITROL rack, speeding up restoration during outages.

- Compatibility: Designed for the UNITROL 5000 platform with typical backward compatibility across board revisions.

- Procurement certainty: Clear part number mapping (UFC760BE1142 / 3BHE004573R1142) minimizes mismatches.

- Lifecycle support: Access to service Ethernet and standard buses simplifies remote diagnostics and parameter management.

- Cost control: Stocking a tested controller board as a strategic spare often saves forced-outage penalties in many cases.

Installation & Maintenance

- Cabinet requirements: Install in a clean, well-ventilated UNITROL 5000 cabinet. Keep ambient within 0…55 °C and avoid condensation.

- ESD handling: Use grounded wrist straps and ESD mats. Avoid touching component surfaces and connector pins.

- Wiring & seating: Power and signals are via backplane; ensure the card is fully seated in guides and locking screws are secured.

- Firmware & parameters: Back up parameters before replacement. After swapping, load the saved configuration and verify setpoints.

- Routine checks: Inspect connectors quarterly, clean dust with dry air, and check event logs for recurring alarms.

- Service access: Use the service Ethernet/maintenance port for diagnostics and commissioning where available.

Quality & Certifications

- CE-marked industrial control component

- RoHS-compliant materials

- Manufactured under ISO 9001 quality systems

- Standard warranty: 365 days

Related Components (for planning)

Typical companions in a UNITROL 5000 rack include UFD-series I/O boards and power interface/firing modules. If you’re refreshing spares, consider pairing the UFC760BE1142 with one digital I/O board and a compatible power interface to cover the most common failure points.

Reviews

There are no reviews yet.