Description

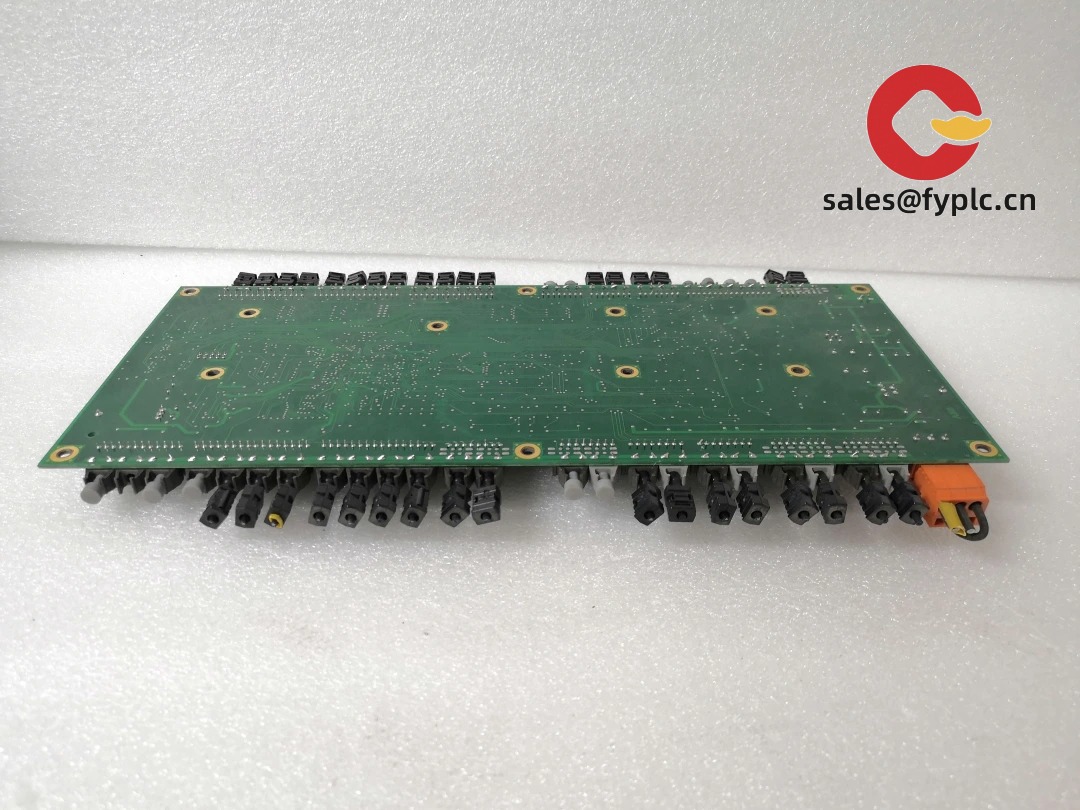

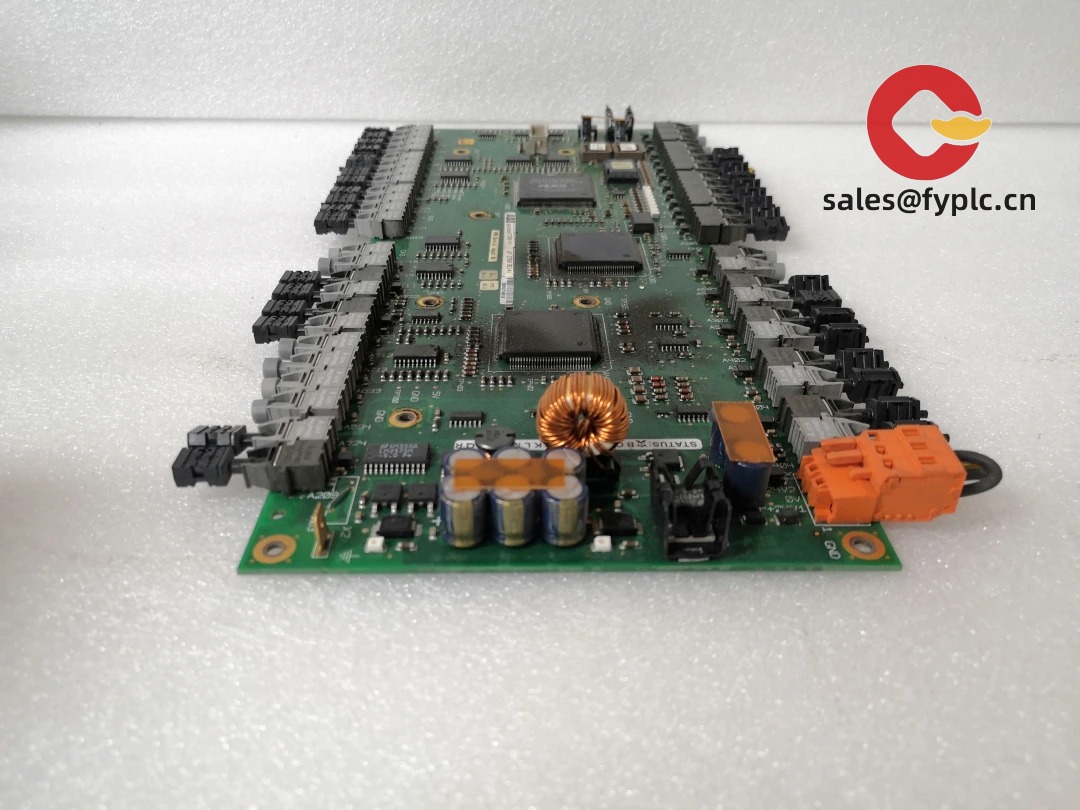

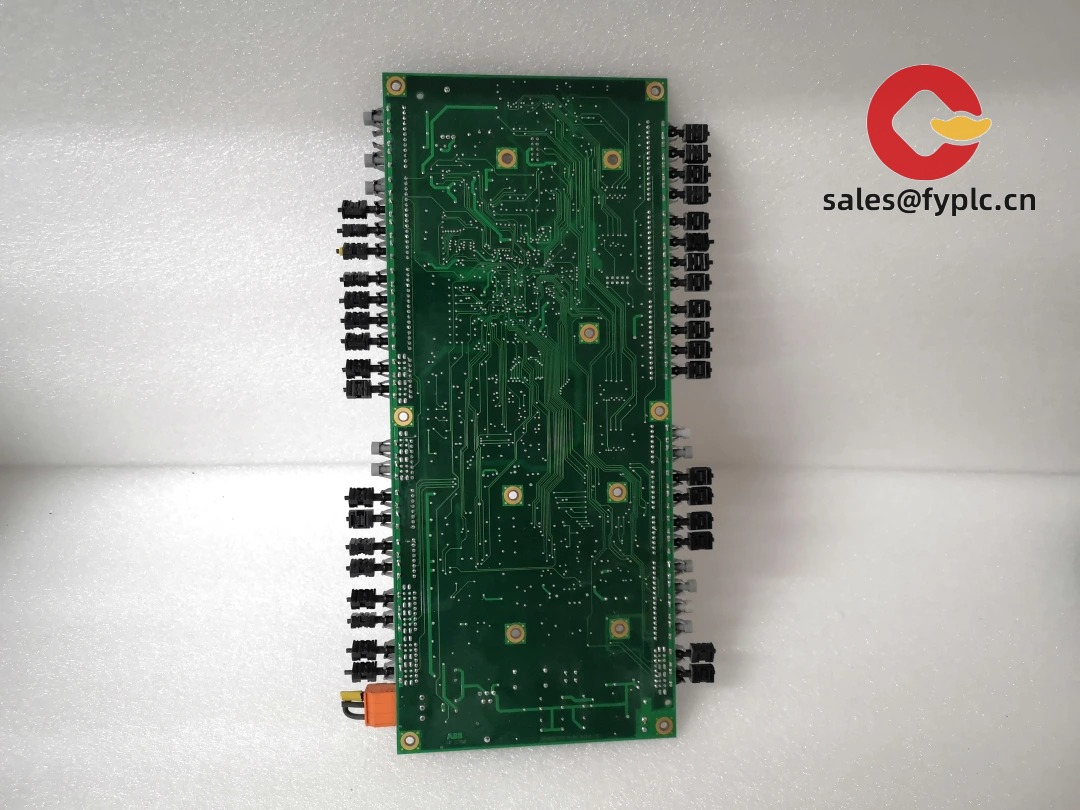

ABB UFC760BE141 (3BHE004573R0141) – High‑reliability DCS controller module for brownfield upgrades and fast spares replacement

The ABB UFC760BE141, order code 3BHE004573R0141, is a controller module widely used in ABB distributed control architectures—typically seen in Symphony/INFI 90 and Harmony installations. From my experience, it’s chosen as a dependable CPU board for plant-life extensions and like-for-like replacements where downtime must be kept to a minimum. You might notice that teams prefer this unit because it drops into existing racks, keeps the original I/O on the bus, and avoids a full system migration. That alone can save weeks of engineering effort and a noticeable chunk of budget.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express couriers: FedEx, UPS, DHL

Key Features

- Drop‑in replacement for legacy ABB racks – Typically installs in existing ABB DCS frames without rewiring field I/O.

- Deterministic control performance – Stable cycle times suited for continuous process control and sequence logic.

- Redundancy-ready architecture – In many cases supports paired controller redundancy to reduce single‑point failures.

- Backplane‑based communication – Works via the system bus; no direct field I/O on the controller, which keeps noise and wiring complexity low.

- Firmware serviceability – Field‑upgradable in most setups; helps standardize versions across units during turnarounds.

- Lifecycle support – Common in brownfield plants where long‑term spares strategies and minimal change control matter.

Technical Specifications

| Brand / Model | ABB UFC760BE141 (Order code: 3BHE004573R0141) |

| HS Code | 8538.90 (Parts suitable for use with switching/control apparatus) |

| Power Requirements | Powered via system backplane (supplied by the cabinet’s system power module) |

| Dimensions & Weight | Plug‑in controller board; occupies one rack slot; typically under 1 kg (varies by revision) |

| Operating Temperature | 0 to +55 °C typical (indoor, ventilated control cabinets) |

| Signal I/O Types | No direct field I/O; interfaces to I/O modules over system bus/backplane |

| Communication Interfaces | System backplane bus; plant network connectivity via dedicated ABB comm modules (revision‑dependent) |

| Installation Method | Rack‑mounted, plug‑in module; secured with front retaining hardware; ESD‑safe handling required |

Application Fields

Plants running ABB DCS platforms—especially those maintaining legacy control cabinets—typically deploy the UFC760BE141 in:

- Power generation (boiler/turbine auxiliaries, BOP control)

- Oil & gas (compressor stations, fractionation, tank farms)

- Chemicals and petrochemicals (reactor control, utilities)

- Pulp & paper (digester, recovery boiler, paper machine sections)

- Water & wastewater (filtration, clarifier, pumping)

- Metals & mining (rolling line auxiliaries, material handling)

Advantages & Value

- Compatibility – Works with installed ABB racks and I/O, avoiding large‑scale rewiring or requalification.

- Reduced downtime – Swap‑and‑commission approach typically keeps outage windows short.

- Cost control – Extends asset life without immediate migration to a new platform.

- Spares strategy – Good as a like‑for‑like spare, especially where validated software versions must be retained.

- Technical backup – We can coordinate firmware matching and basic version checks to align with your installed base.

Installation & Maintenance

- Cabinet & mounting – Install in the designated ABB rack slot; maintain clear airflow; follow the cabinet’s grounding scheme.

- Power & wiring – Confirm the system power module health before insertion; de‑energize the slot as per site LOTO procedure when applicable.

- ESD handling – Use antistatic wrist straps and bags; avoid touching signal pins and edge connectors.

- Commissioning – Match firmware/loader versions to the installed base; restore application from validated backups; verify bus health LEDs.

- Routine care – Quarterly dust removal with dry air (low pressure), check connector tightness, review diagnostic logs; firmware updates only during planned outages.

A maintenance planner from a mid‑sized power plant told us they swapped a failing controller for this model during a six‑hour window and kept all field I/O untouched—no loop revalidation needed. That seems to be the sweet spot for plants that can’t afford long stops.

Supporting Components & Related Models

- System power supply modules for the ABB rack (to provide stable backplane power)

- Backplane/rack assemblies compatible with Symphony/INFI‑style controller slots

- Communication interface modules for plant network links (revision‑dependent)

- Remote and local I/O modules on the same bus for analog, digital, and specialty signals

- Spare front‑panel retaining hardware and ESD‑safe service kits

Quality & Certifications

- Manufacturer quality systems typically certified to ISO 9001

- CE compliance for EMC and safety (industrial environment)

- RoHS conformity for hazardous substances (where applicable)

- Warranty coverage: 365 days

If you want, share your installed controller revision and current firmware levels—we can help verify compatibility and propose a practical replacement path with realistic lead times.

Reviews

There are no reviews yet.