Description

ABB UNITROL1010 3BHE035301R1002 – Digital AVR for Brushless Synchronous Generators and Motors

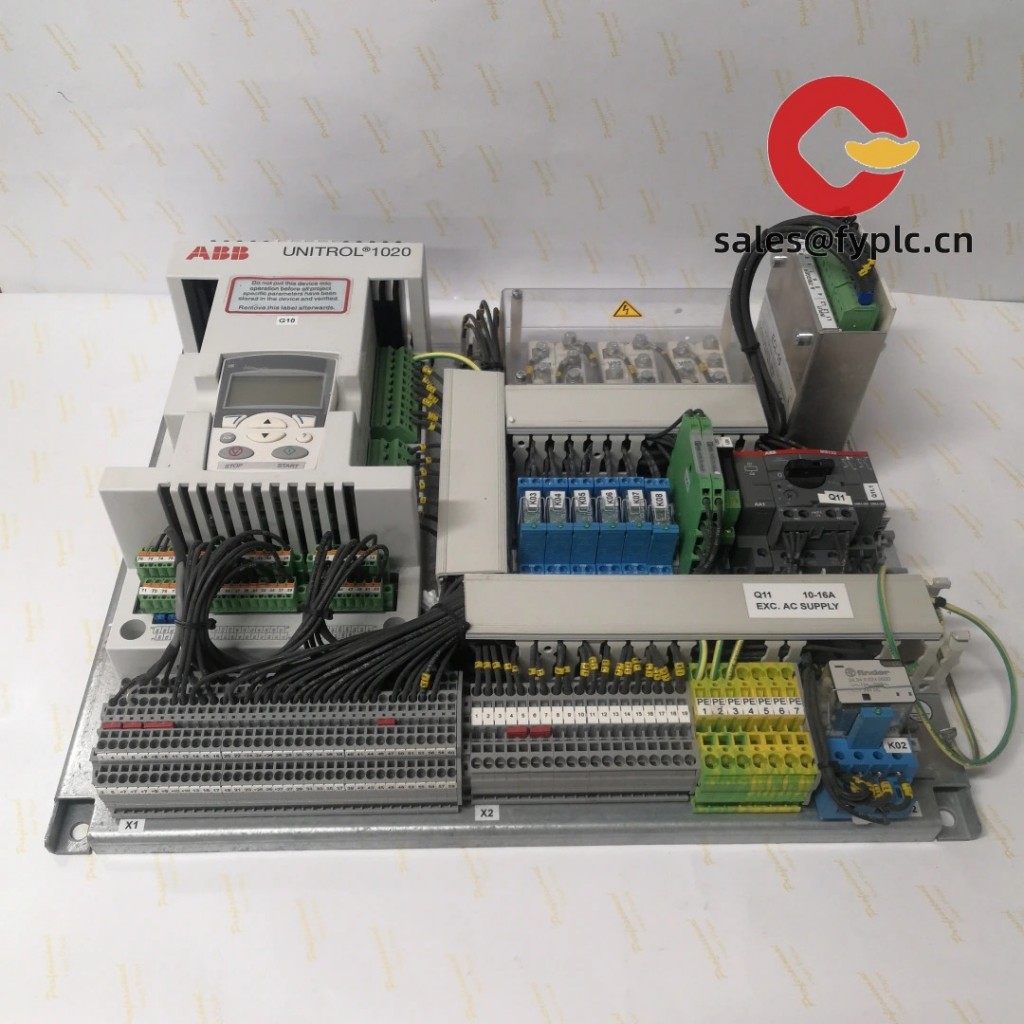

The ABB UNITROL1010 is a compact, microprocessor-based automatic voltage regulator built for stable, precise excitation control on brushless synchronous machines. The 3BHE035301R1002 variant sits in the proven UNITROL 1000 family, which typically serves industrial gensets, CHP plants, small hydro, and marine auxiliaries. From my experience, it delivers fast voltage response, clean steady-state regulation, and dependable protection features that operators actually use—over/under excitation limiters, soft-start, U/f droop, PF/VAR control, and a practical event log for troubleshooting.

Our Order Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week when in stock; no more than 1 month latest

- Payment: 50% advance; remaining balance prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Digital AVR control – Stable voltage regulation with fast response and low ripple, suited for variable load conditions.

- PF/VAR and U/f droop modes – Lets you run voltage, power factor, or reactive power control depending on grid or islanded needs.

- Robust protection & limiters – Over/under excitation limiters, overvoltage/undervoltage, loss-of-sensing supervision to protect the machine.

- Industrial I/O set – Voltage sensing inputs, CT input for compensation/droop, configurable analog/digital I/O, and relay outputs for alarms or interlocks.

- Integrated communication – Typically supports RS‑485 (Modbus RTU) and a service USB port for parameterization and diagnostics.

- Commissioning-friendly – PC-based setup with trending and event records. One thing I appreciate is how parameter groups make tuning repeatable across units.

- Compact footprint – Designed for panel/backplate mounting in generator control panels where space is tight.

Technical Specifications

| Brand / Model | ABB UNITROL1010, code 3BHE035301R1002 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments) |

| Main Function | Digital automatic voltage regulator for brushless synchronous generator/motor excitation |

| Power Requirements | Auxiliary supply 24 VDC (typically 18–32 VDC) |

| Operating Temperature | Typically −20 to +55 °C (non-condensing environment) |

| Signal I/O Types | Voltage sensing (up to 3‑phase), CT input, configurable analog inputs/outputs, digital inputs, relay outputs |

| Communication Interfaces | RS‑485 (Modbus RTU), service USB; options can vary by factory variant |

| Control Modes | AVR, PF, VAR, U/f droop; power system stabilizer features available in many cases |

| Installation Method | Panel/backplate mounting inside generator control cabinet; wiring via pluggable terminals |

Application Fields

Typical deployments include industrial gensets, standby and prime-power plants, CHP and biogas units, small hydro turbines, and marine auxiliary generators. You might notice that it also fits well on retrofit projects where a legacy AVR needs a modern, communication-ready replacement without redesigning the entire panel.

- Industrial plants and mining sites looking for stable PF/VAR control to avoid penalties

- Small utilities and microgrids requiring coordinated droop sharing and fast recovery after load steps

- Marine and offshore skids where compact footprint and vibration-tolerant mounting are valued

- OEM genset builders seeking a standard, repeatable tuning process across multiple machine ratings

Advantages & Value

- Reliability – Solid-state design with protective limiters reduces nuisance trips. In many cases, we’ve seen tighter voltage stability under motor-start conditions.

- Compatibility – Works with standard PT/CT sensing; common I/O and Modbus ease integration with PLCs and genset controllers.

- Lower lifecycle cost – Quick commissioning, built-in diagnostics, and remote monitoring typically cut site time and support calls.

- Global support – ABB’s service network and long product roadmap help standardize spares across fleets.

A maintenance supervisor at a food processing plant told us their switch to UNITROL1010 “stopped the hunting we had on lighter loads, and trending made it obvious which settings mattered.” That seems to be a common theme on retrofits.

Installation & Maintenance

- Panel environment – Mount on a rigid backplate inside a ventilated cabinet. Maintain clear airflow; avoid direct heat sources and conductive dust.

- Wiring practices – Use shielded twisted pairs for sensing and communication. Separate power and signal wiring; ground shields at one point to reduce noise.

- Protection coordination – Verify CT/VT ratios and polarity. Check limiters and alarms before first excitation; set PF/VAR mode to match your grid code or paralleled controller.

- Routine care – Periodically check terminal torque, clean filters, back up parameters, and apply firmware updates when recommended by ABB. Annual functional tests (step response, limiter checks) are typically sufficient.

- Safety – De-energize and discharge field circuits before service. Follow lockout/tagout and wait for capacitors to bleed down.

Quality & Certifications

- CE marked; RoHS compliant

- UL/cUL conformity available on many UNITROL1010 variants (check code 3BHE035301R1002 for regional approvals)

- Manufacturer’s warranty: 12 months (365 days)

If you’re matching an existing exciter or planning a drop‑in retrofit, share your generator rating, PT/CT details, and desired control mode. We’ll validate that the UNITROL1010 3BHE035301R1002 variant aligns with your I/O and communication needs before shipping—saves surprises at site.

Reviews

There are no reviews yet.