Description

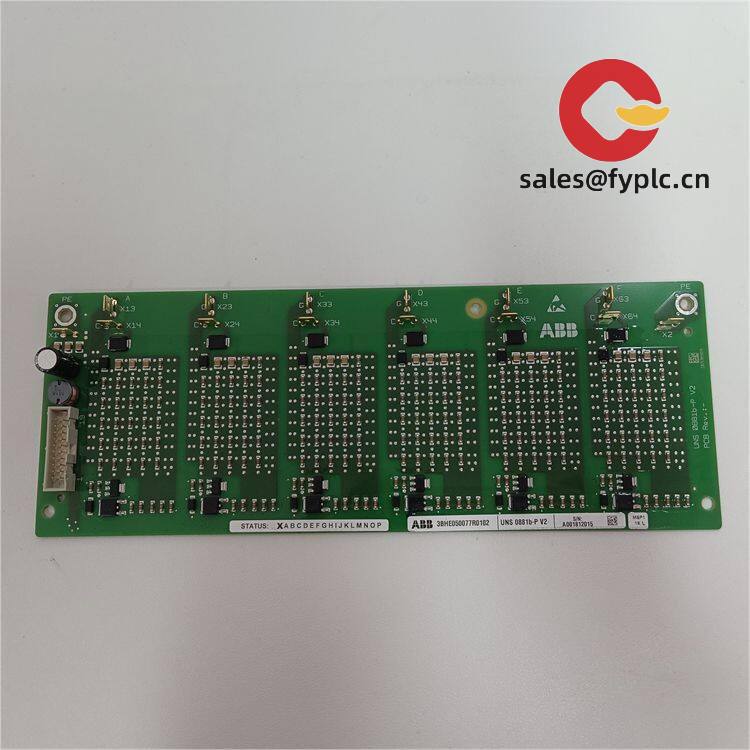

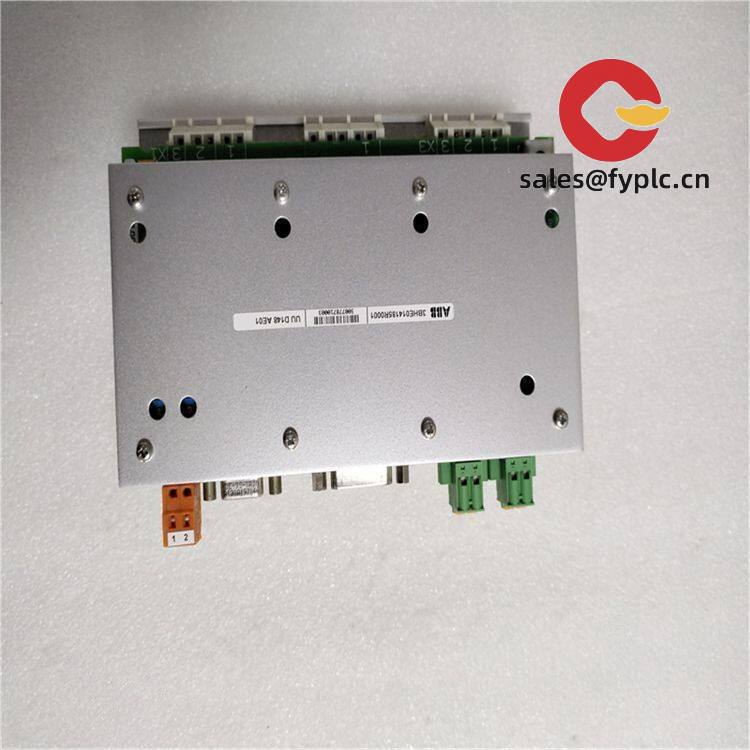

ABB UUD148AE01 (3BHE014185R0001) – High‑speed I/O Board for AC 800PEC and Power Electronics Control

The ABB UUD148AE01, part number 3BHE014185R0001, is a plug‑in board widely used with the ABB AC 800PEC high‑performance controller platform. From my experience, it’s selected when you need fast, deterministic I/O handling in demanding applications—medium‑voltage drives, converters, or lab test rigs where microsecond‑level timing actually matters. You might notice that it tends to slot straight into existing PEC subracks with minimal rework, which is a relief for maintenance teams working under time pressure.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

- Each unit is inspected and securely packed; ESD and moisture barrier packaging are used in most cases

Key Features

- AC 800PEC ecosystem fit – Designed for ABB’s high‑speed PEC architecture, typically used in power electronics control.

- Fast digital I/O handling – Optimized for deterministic signal processing; suitable for interlocks, gating, or fast status capture.

- Galvanic isolation – I/O channels are typically opto‑isolated to reduce ground loops and noise ingress in high‑EMI environments.

- Backplane communication – Direct interface to the PEC backplane for low‑latency data exchange with the CPU board.

- Serviceability – Front‑panel access, status indication, and plug‑in form factor keep swap‑out times short.

- Industrial build quality – ABB board‑level design with robust components; conformal coating variants are common in many installations.

Technical Specifications

| Brand / Model | ABB UUD148AE01 (3BHE014185R0001) |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537 – industrial control parts) |

| Power Requirements | 24 VDC nominal via AC 800PEC backplane; typical consumption 6–10 W |

| Dimensions & Weight | Plug‑in board for PEC subrack; approx. 6U, 160 mm depth; ~0.4–0.6 kg |

| Operating Temperature | 0 to +55°C (installed in a ventilated cabinet); storage typically −25 to +70°C |

| Signal Input/Output Types | High‑speed digital I/O, 24 VDC logic levels, opto‑isolated; intended for fast status/control signals |

| Communication Interfaces | AC 800PEC backplane interface; field wiring via front connectors |

| Installation Method | Subrack plug‑in card; front‑panel fastening; connectors accessible from the front |

Application Fields

The UUD148AE01 is commonly deployed with AC 800PEC‑based systems in:

- Medium‑voltage drives (e.g., PEC‑controlled ACS platforms) for synchronous/induction machines

- Power converters and rectifier/inverter controls in metals, mining, and marine

- Wind and renewable converter controls where fast gating and protection signals are critical

- High‑power test benches and lab rigs requiring deterministic I/O timing

A maintenance lead at a steel plant told us it dropped straight into their existing PEC rack and cleared a stubborn I/O fault that had been causing nuisance trips—no application code changes were needed in their case.

Advantages & Value

- Reliability – Proven ABB hardware; stable behavior in electrically noisy rooms and MV drive halls.

- Compatibility – Appears to be fully compatible with AC 800PEC subracks and backplane signaling; helps extend asset life.

- Cost control – A targeted board replacement often avoids an unnecessary controller upgrade.

- Lead time – We aim for rapid shipment on stocked units; helpful when a line is down.

- Support – Guidance on installation, basic checks, and firmware compatibility notes when applicable.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated cabinet meeting IEC/UL industrial control standards; avoid condensation and conductive dust.

- ESD handling – Use antistatic wrist straps and ESD mats; keep the board in shielding bags until installation.

- Backplane & wiring – Power is provided via the PEC backplane; field I/O should use twisted‑pair, shielded cables where noise is present.

- Grounding – Ensure functional earth is reliable; separation of power and signal grounds reduces interference.

- Checks after replacement – Verify channel polarity/levels, run self‑test or diagnostics LEDs, and confirm CPU firmware recognizes the board.

- Routine maintenance – Periodic connector re‑seating, dust cleaning with dry air, and visual inspection for hot spots; firmware updates only if recommended by the site standard.

Quality & Certifications

- Typically CE‑marked for industrial environments

- UL/CSA applicability depends on system integration and cabinet certification

- RoHS compliance may vary by production date; many legacy service parts are RoHS‑exempt under industrial categories

- Manufacturer warranty practices vary by region; our supplied units carry a 365‑day warranty

Related and Supporting Components

- AC 800PEC CPU/main controller boards (e.g., PPC‑series) for high‑speed control execution

- PEC subrack/backplane assemblies and power distribution modules

- Front terminal blocks and field wiring harnesses suited to the UUD‑series I/O

Reviews

There are no reviews yet.