Description

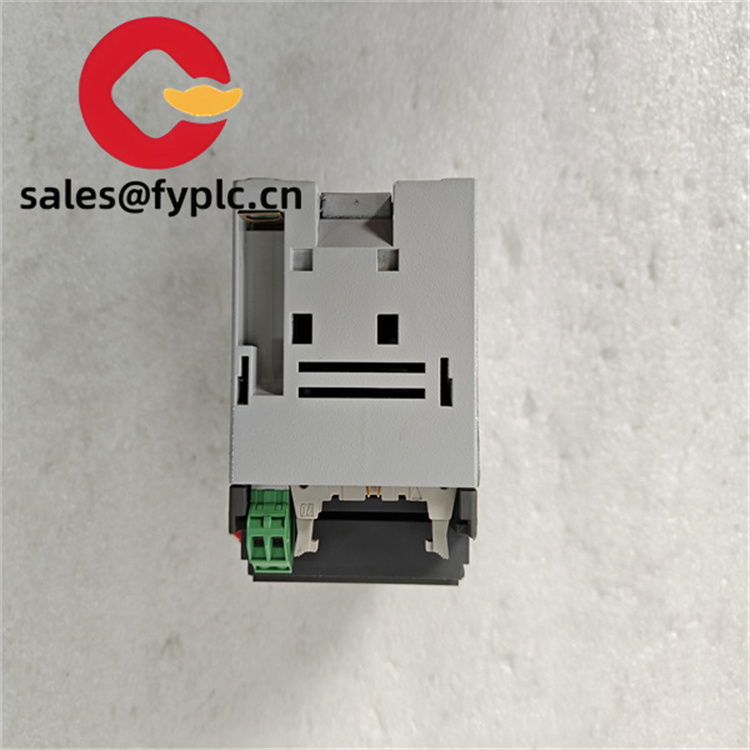

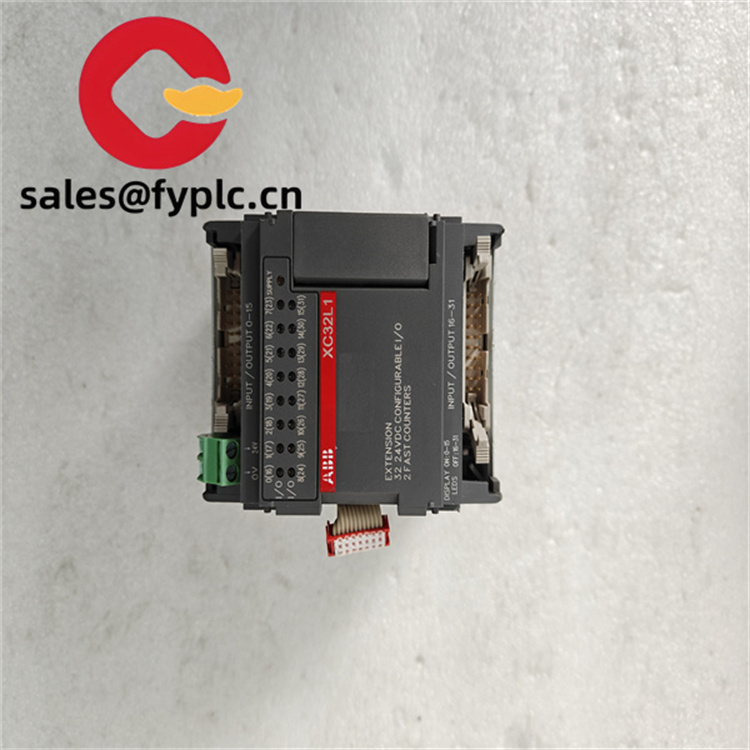

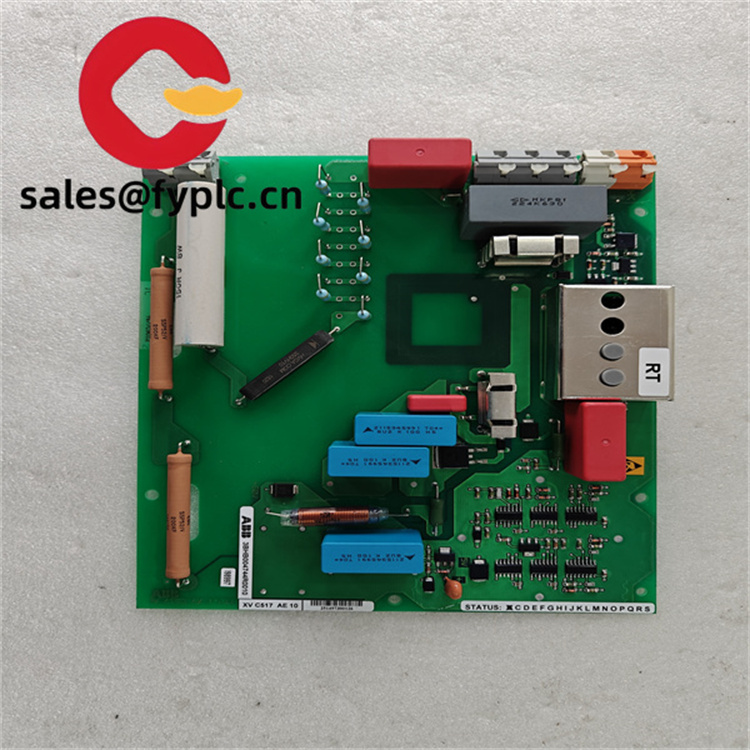

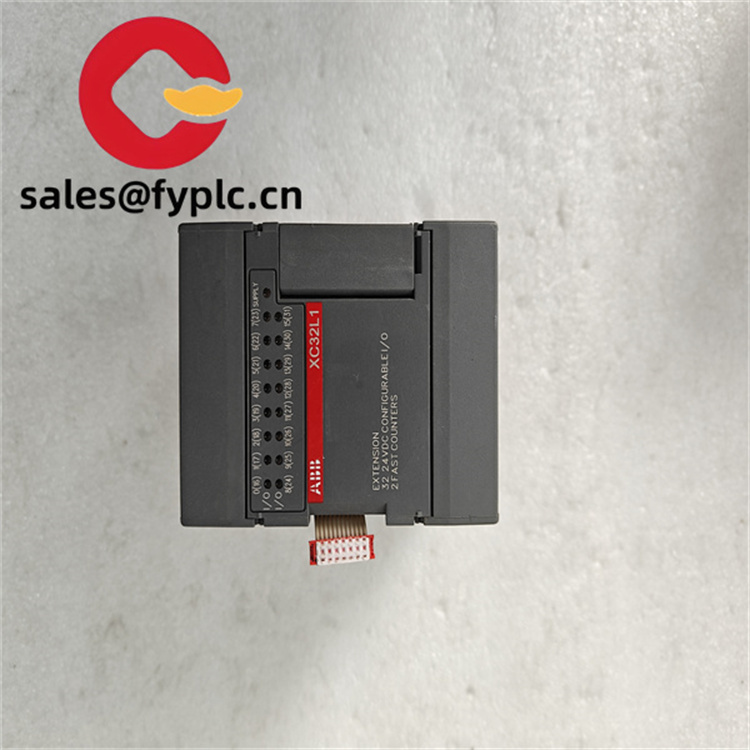

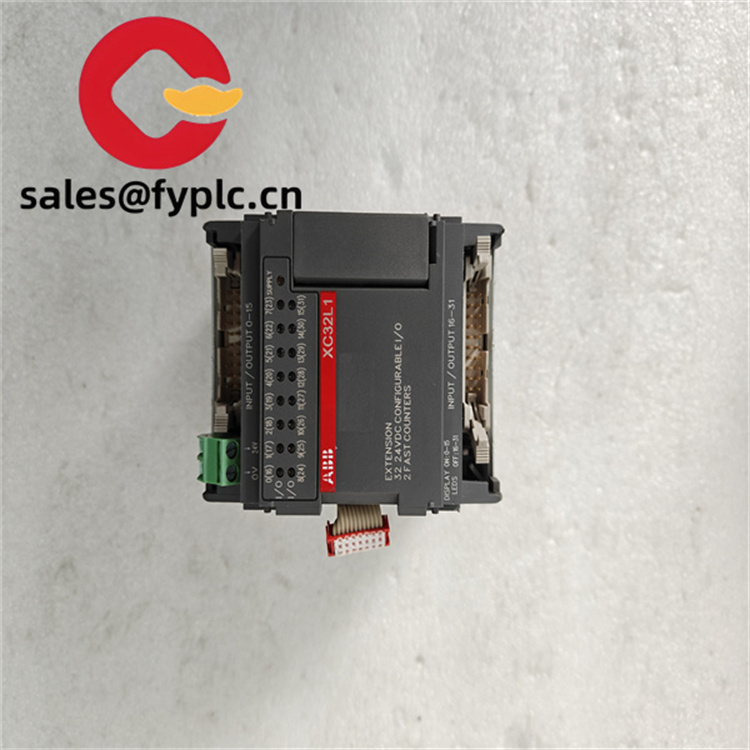

ABB XC32L1-A2.0 indirect excitation system functional module

In the ever – evolving landscape of industrial automation, ABB’s XC32L1 – A2.0 stands out as a core component in industrial control systems, thanks to its superior performance and innovative technology. As a high – performance Programmable Logic Controller (PLC), the ABB XC32L1 – A2.0 is specifically designed to meet the complex and changing automation needs of modern industries. From the critical process control in large energy plants to the intelligent production line management in precision manufacturing workshops, it achieves precise control and efficient data processing through its powerful functions. This provides a solid support for the stable operation and optimized upgrading of industrial systems.

| Label |

Specification |

| Model Number |

XC32L1 – A2.0 |

| Brand |

ABB |

| Type |

Programmable Logic Controller |

| Input Voltage |

24V DC, compatible with various industrial DC power supplies to ensure power supply stability and lay a solid foundation for the reliable operation of the equipment |

| Operating Temp |

-25°C – 70°C, capable of continuous and stable operation in extreme temperature environments, regardless of the impact of severe cold or heat on equipment performance |

| Communication Method |

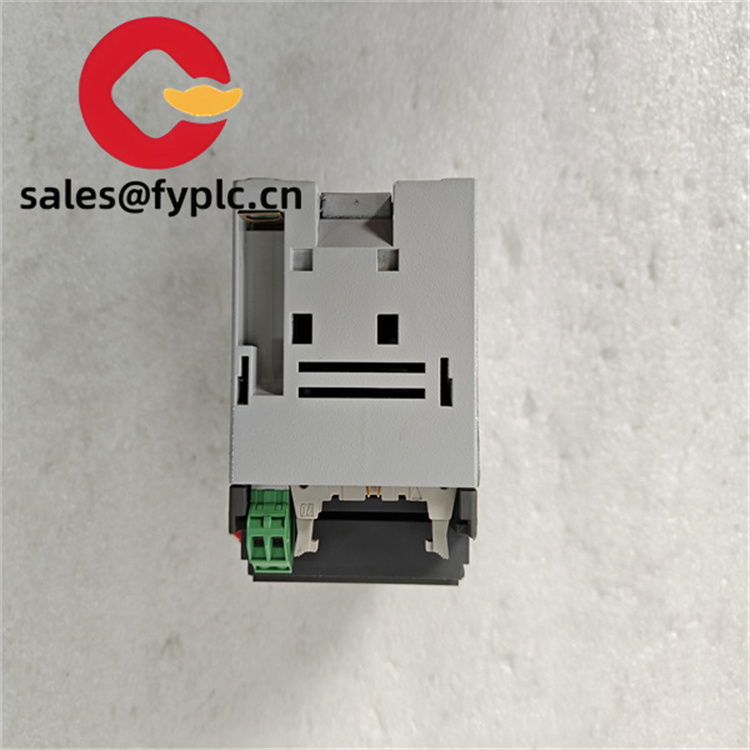

Ethernet, PROFINET, Modbus TCP, with rich communication methods to help achieve seamless integration with various devices and systems |

| Mounting |

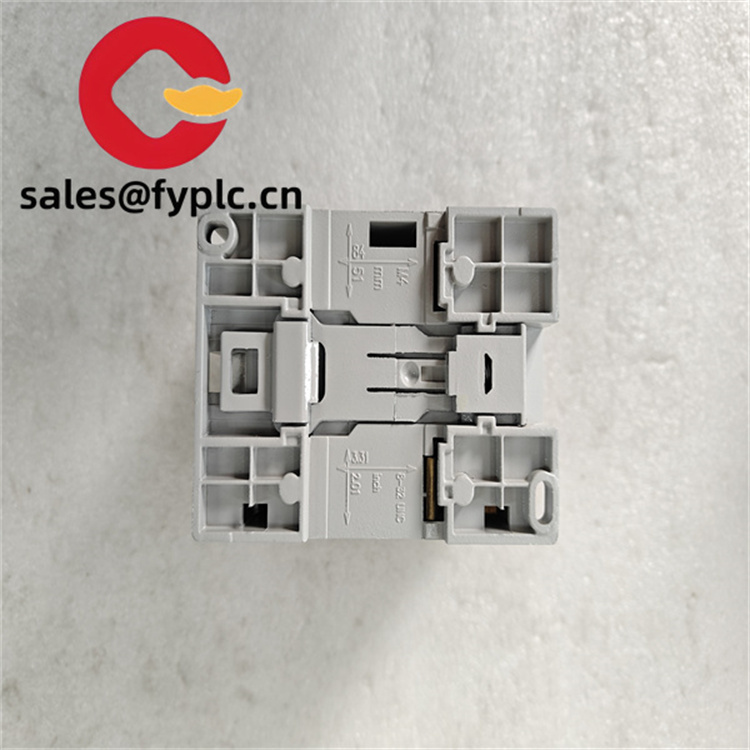

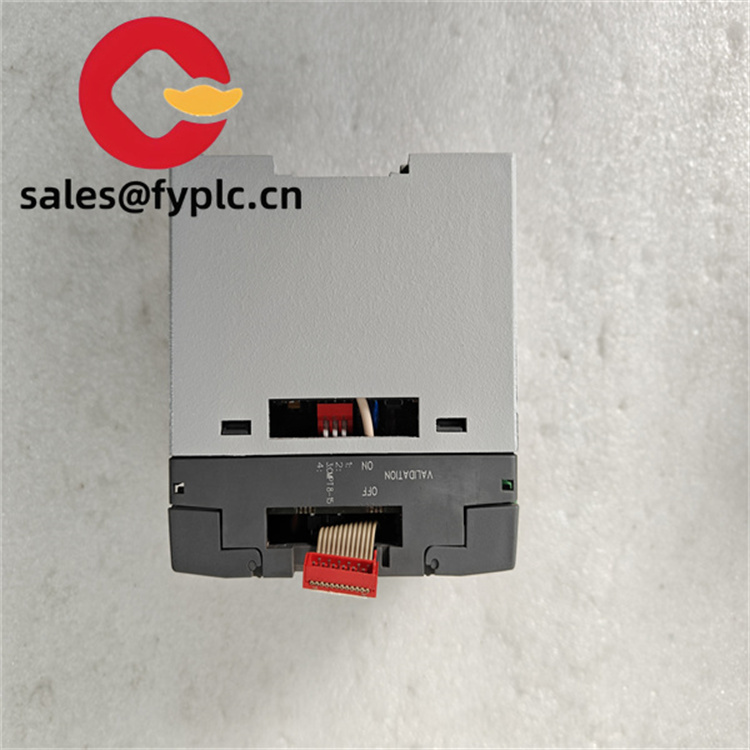

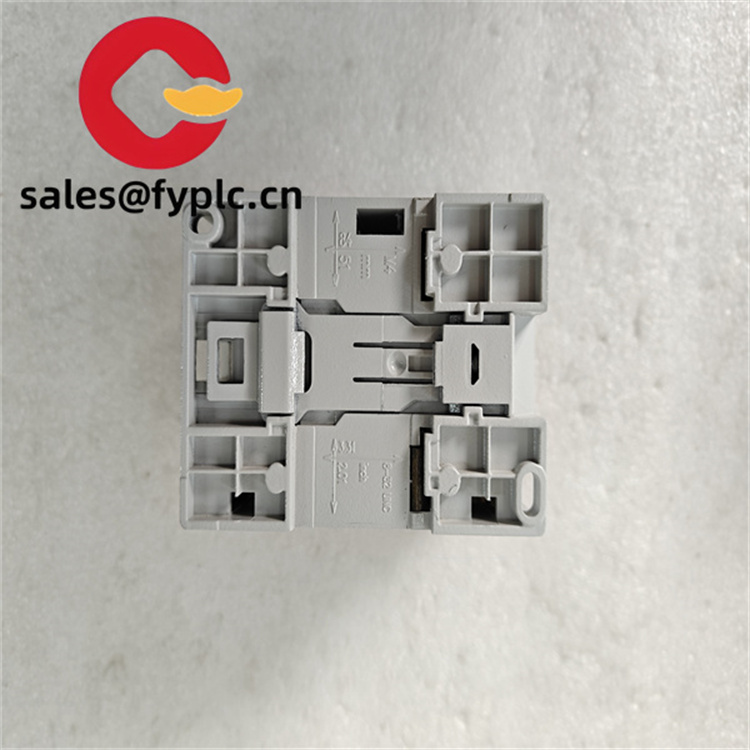

Standard DIN rail mounting, convenient and stable, facilitating quick layout and installation in industrial control cabinets |

| Weight |

[Specific weight, refer to the product manual], with a compact and lightweight design for flexible deployment in different industrial devices |

| Certifications |

CE, UL, ISO 9001, etc., passing a number of international authoritative certifications, with product safety and quality reaching industry – leading levels |

| Dimensions |

[Length × Width × Height (mm)], with a reasonable size design to adapt to various space installation scenarios |

| IP Rating |

IP20, which can effectively protect against large – size solid foreign objects and ensure the normal operation of the equipment in conventional industrial environments |

| Protocols Supported |

TCP/IP, UDP, ABB’s exclusive communication protocols, with strong protocol support capabilities to improve equipment compatibility and interconnection |

ABB XC32L1 – A2.0 demonstrates many remarkable advantages and unique design highlights in actual industrial scenarios. With an advanced multi – core processor architecture, it has extremely fast data processing speed and powerful logical computing capabilities, and can quickly respond to and execute complex control instructions. In the precision machining production line of auto parts, the ABB XC32L1 – A2.0 can accurately control the movement trajectory of machine tools, the timing of tool changes, and processing parameters, and real – time monitor various data in the processing process. It dynamically adjusts the processing strategy according to the actual situation to ensure that the processing accuracy of each part meets strict standards, greatly improving production efficiency and product yield.

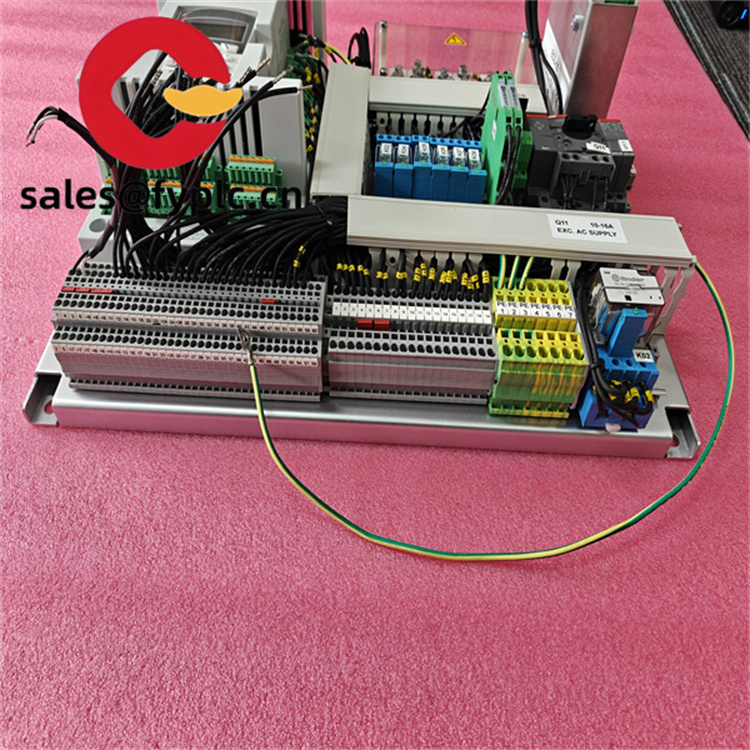

Its design fully considers the harsh challenges of the industrial environment and has excellent anti – electromagnetic interference capabilities and mechanical stability. Even in a cluster of electrical equipment with strong electromagnetic interference or in a heavy – machinery operation environment with frequent vibrations, the ABB XC32L1 – A2.0 can still operate stably, effectively reducing the risk of system failures. In addition, the controller has a high degree of scalability and compatibility and supports a wide range of ABB and third – party I/O modules, sensors, and actuators. In a large – scale automated warehousing system, it can connect various sensors to achieve precise positioning of goods and inventory monitoring, and at the same time control actuators such as robotic arms and shuttle cars to achieve fully automated management of warehouse logistics. The modular design makes maintenance work more efficient. Once a module fails, technicians can quickly locate and replace it, greatly reducing downtime and lowering enterprise operating costs.

ABB XC32L1 – A2.0 plays a key role in multiple industries and brings significant value improvement to industrial production. In the smart substations of the power industry, it is responsible for real – time monitoring and control of various equipment in the substation, such as circuit breakers, disconnectors, and transformers. By accurately collecting equipment operation data, the ABB XC32L1 – A2.0 can timely detect equipment anomalies and issue warnings, and automatically execute fault isolation and recovery operations to ensure the safe and stable operation of the power system. At the same time, it can also optimize the operation parameters of the substation, improve power transmission efficiency, and reduce energy consumption.

In the chemical production field, the ABB XC32L1 – A2.0 is used to control complex chemical reaction processes. It accurately adjusts key parameters such as reaction temperature, pressure, and material ratio to ensure that chemical reactions proceed under safe and efficient conditions. Once the parameters deviate from the set range, it immediately triggers an alarm and automatically adjusts the relevant equipment to prevent accidents. In addition, it can also carry out automated control of the waste gas and wastewater treatment links in the production process, helping chemical enterprises achieve the goal of green production.

- ABB AC500 – eCo PLC: Also a PLC product under ABB, it focuses on small – scale automation projects and is suitable for scenarios with strict requirements on cost and space. It can work in coordination with the XC32L1 – A2.0 in distributed systems.

- ABB PM866AK01 Controller Module: Used in conjunction with the XC32L1 – A2.0, it can enhance the overall computing and control capabilities of the system and is suitable for large and complex industrial control systems.

- ABB AI810 Analog Input Module: It can be seamlessly connected to the XC32L1 – A2.0 to achieve accurate acquisition of various analog signals and is widely used in industrial scenarios requiring real – time monitoring of physical quantities.

- ABB DO810 Digital Output Module: It can cooperate with the XC32L1 – A2.0 to achieve precise control of external equipment, such as motor start/stop and valve switch operations.

- ABB CI840 Communication Interface Module: It expands the communication capabilities of the XC32L1 – A2.0, supports more communication protocols, and improves the interconnection between the system and different devices.

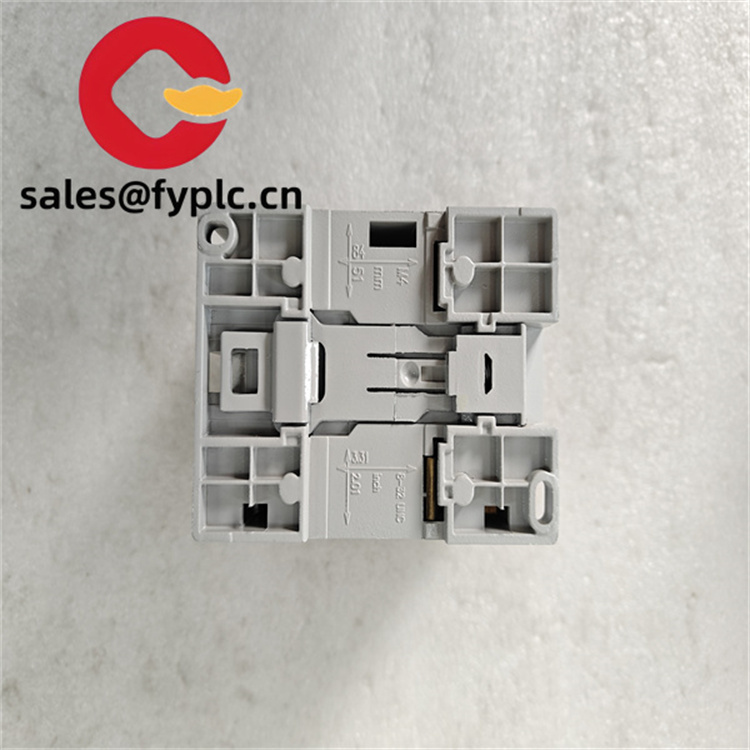

When installing the ABB XC32L1 – A2.0, the installation specifications must be strictly followed. Before DIN rail installation, ensure that the rail is firmly installed and reliably grounded. Fix the XC32L1 – A2.0 firmly on the rail to avoid performance degradation caused by looseness due to equipment operation vibration. During electrical connection, be sure to accurately connect the power supply line, communication line, and I/O signal line according to the detailed wiring diagram. Select cables of appropriate specifications and ensure tight connections to prevent signal transmission failures or equipment anomalies caused by poor contact.

For more information, please click below to learn more:

Reviews

There are no reviews yet.