Description

ABB XO08R2 (1SBP260109R1001) – 8‑channel relay output module for robust industrial switching

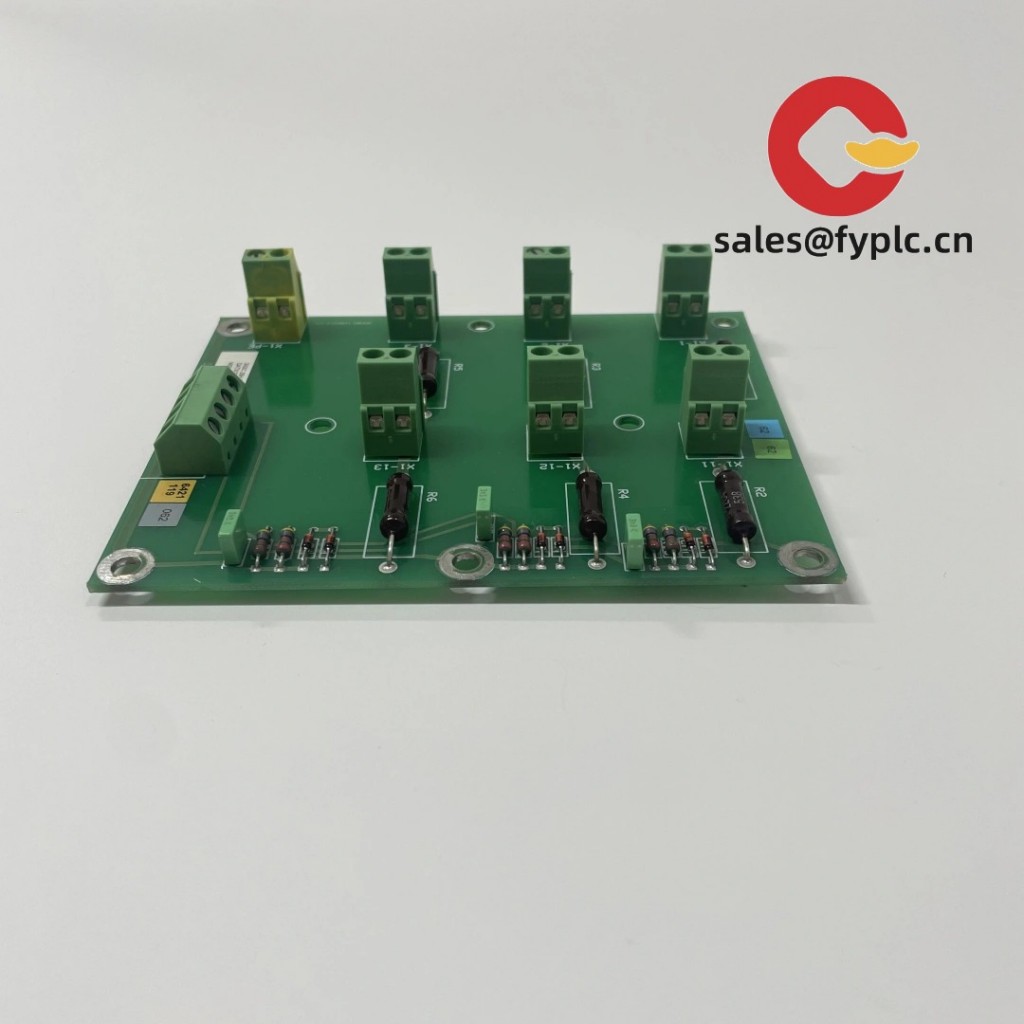

The ABB XO08R2 with part number 1SBP260109R1001 is an 8‑channel relay output module used for driving solenoids, contactors, lamps, and other discrete loads from a PLC or DCS. From my experience, this type of module is chosen when you need galvanic isolation and wide load flexibility—AC or DC—without worrying about leakage current or field device compatibility. You might notice that the channel status LEDs and labeled terminals make commissioning straightforward, which typically shortens I/O checkout time during FAT/SAT.

Our Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 8 isolated relay outputs – Potential‑free contacts provide broad compatibility with AC/DC loads and clear electrical separation from logic.

- Channel status indication – Individual LEDs per channel help verify wiring and speed up troubleshooting in many cases.

- Industrial contact ratings – Suited to switching typical panel devices like interposing relays, valves, beacons, and small contactors.

- Noise immunity – Relay isolation and shielding practices reduce cross‑talk on mixed‑signal cabinets.

- Pluggable terminals – Service‑friendly wiring with labeled terminals for quick replacement during outages.

- Backplane/rail integration – Designed to integrate into ABB control cabinets with tidy field power distribution and diagnostics.

Technical Specifications

| Brand / Model | ABB XO08R2, Part No. 1SBP260109R1001 |

| HS Code | 853890 (Parts for electrical control/switchgear) |

| Power Requirements | 24 V DC nominal for relay drive/backplane supply (typical for this series) |

| Operating Temperature | Typically 0…55 °C (indoor control cabinet) |

| Signal Input/Output Types | 8 relay outputs, potential‑free contacts; per‑channel status LEDs |

| Communication Interfaces | Backplane bus to host controller; no external comms on the front |

| Installation Method | DIN‑rail/backplane mounting with pluggable terminal blocks; panel‑protected environment with ventilation |

| Dimensions & Weight | Compact I/O module form factor; typically < 200 g |

Application Fields

Commonly used in discrete and hybrid automation where clean isolation and reliable switching are key:

- Machine building (conveyors, packaging, material handling)

- Process skids (valves, pumps, interlocks) tied to DCS/PLC logic

- Utilities and water treatment (dampers, dosing valves, alarms)

- Building and infrastructure systems (fans, lighting, signaling)

- Brownfield retrofits replacing aging relay output cards with minimal rewiring

Advantages & Value

- Reliability in mixed loads – Relay contacts handle inductive and resistive loads better than many transistor cards, which in many cases reduces nuisance trips.

- Compatibility – Potential‑free outputs simplify integration with third‑party devices and legacy circuits.

- Maintenance friendly – Clear channel indication and pluggable terminals speed swap‑outs during short shutdowns.

- Cost control – One module covers AC/DC loads, typically avoiding extra interposing relays for light/medium duty circuits.

A site engineer told us they replaced mixed transistor cards with XO‑series relay outputs on a wastewater line; “fault calls dropped right away,” mostly because the pump starters and beacon stacks were happier with fully isolated contacts.

Installation & Maintenance

- Cabinet environment – Mount on a grounded DIN rail in a clean, ventilated panel; keep ambient within the stated temperature range.

- Wiring – Use appropriately rated conductors; keep signal and power wiring separated; torque terminal screws per spec.

- Load protection – For inductive loads (coils, solenoids), fit flyback diodes (DC) or RC snubbers (AC) to extend contact life.

- Power – Provide stable 24 V DC field/backplane supply; verify commons and shielding to avoid ground loops.

- Checks – During commissioning, exercise each channel and confirm indicator LEDs and field actuation; log channel assignments in the I/O list.

- Routine care – Inspect terminals for loosening and dust; re‑tighten seasonally; keep a spare module configured for fast swap.

- Safety – De‑energize field power and apply lockout/tagout; relay contacts may carry hazardous voltages—verify absence before handling.

Quality & Certifications

- Conformity – CE compliant; manufactured under ISO 9001 quality systems

- RoHS – RoHS compliant materials, typically used across ABB low‑voltage electronics

- Warranty – 365‑day warranty coverage

One thing I appreciate is how forgiving relay output cards are during retrofits—wire in, check the LED, and you’re usually done. If you share a photo of your panel layout, we can confirm terminal mapping so the XO08R2 drops in with minimal rework.

Reviews

There are no reviews yet.