Description

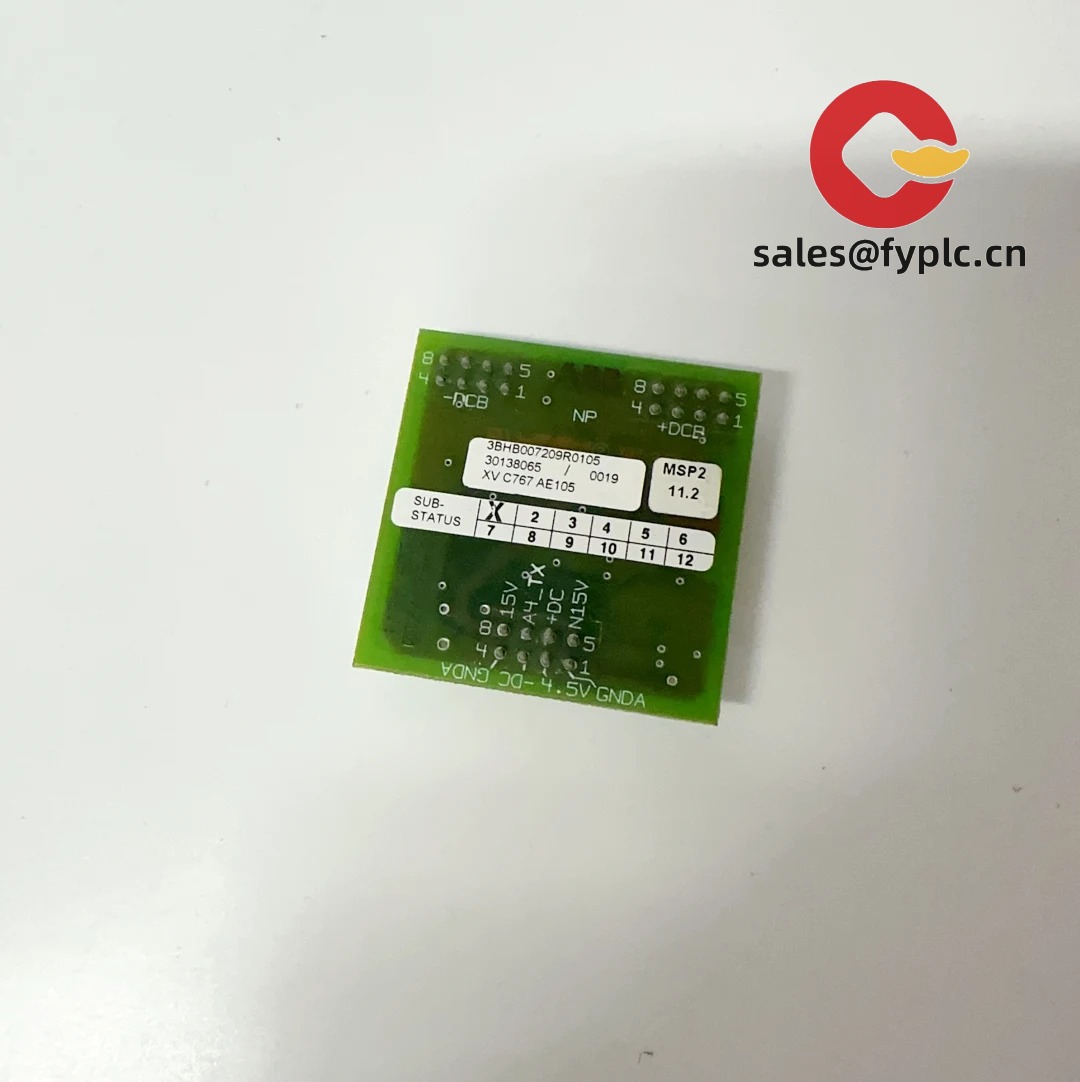

ABB XVC767AE105 (3BHB007209R0105) – Control Board for ABB Drive Systems

The ABB XVC767AE105, matched to ABB’s internal part number 3BHB007209R0105, is a plug-in control board used within ABB industrial drive systems. From my experience, it’s typically deployed as a replacement or upgrade board in ABB drive cabinets to restore control logic, internal communication, and signal handling without reworking the entire drive. Maintenance teams choose it because it drops in fast, keeps existing wiring intact, and gets production back online with minimal tuning.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items, no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

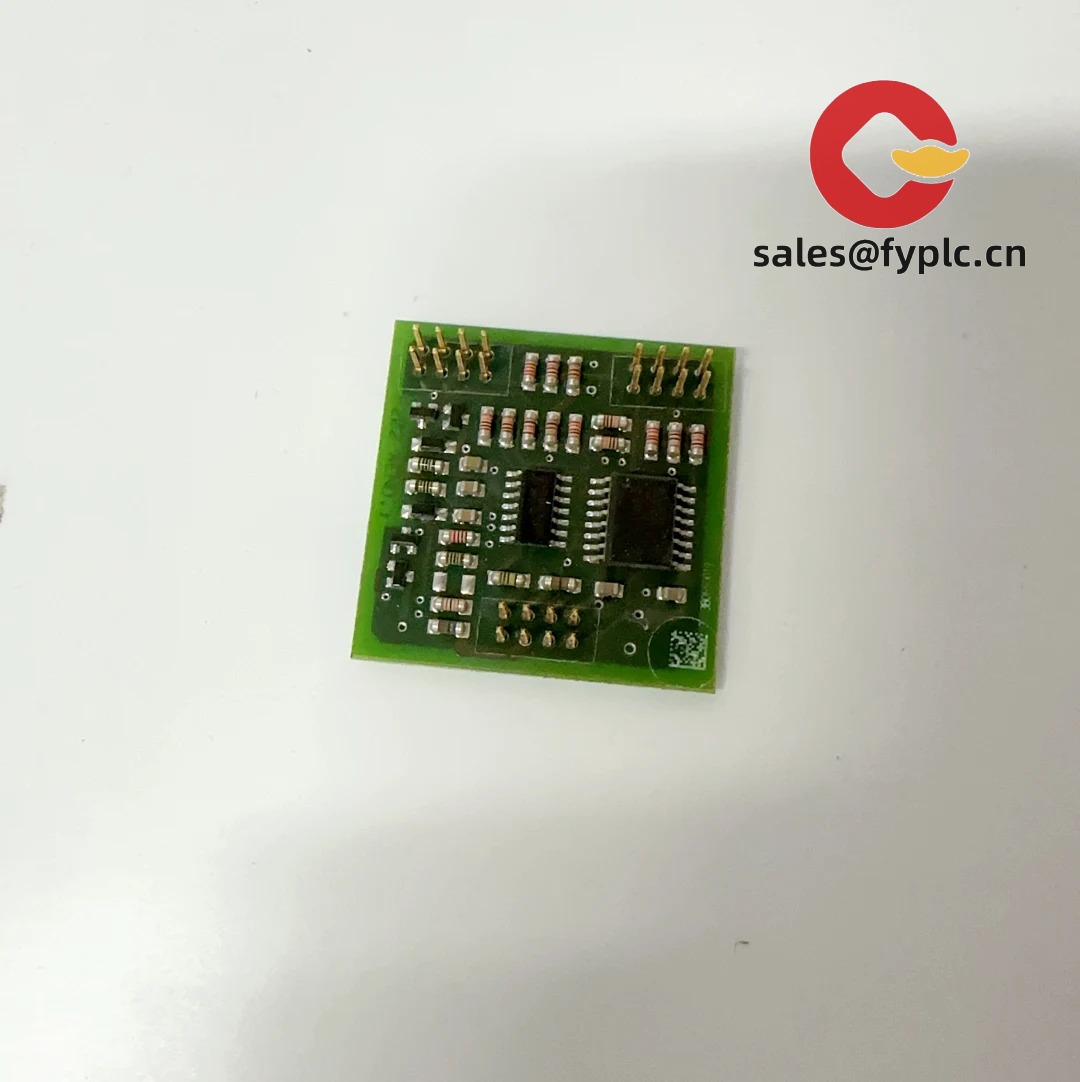

- Form-fit replacement – Designed to fit ABB drive cabinets with existing backplane and connectors, so changeover is quick.

- Stable drive control – Maintains internal control logic and signal processing that many ABB drives rely on during speed/torque loops.

- Host-powered design – Draws low-voltage power from the drive; no external supply typically required.

- Service-friendly – Supports standard ABB maintenance routines (parameter backup/restore, board swap under controlled shutdown).

- Field-proven reliability – In many cases, plants report reduced nuisance trips after replacing aging boards with the XVC767AE105.

Technical Specifications

| Brand / Model | ABB XVC767AE105 |

| Manufacturer Part No. | 3BHB007209R0105 |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Supplied via host drive/PLC backplane; typically 24 VDC, low power consumption |

| Operating Temperature | Typically 0 to +55 °C inside a compliant control cabinet |

| Signal I/O Types | Interfaces to the host drive’s internal control signals; I/O availability depends on drive configuration |

| Communication Interfaces | Proprietary ABB internal buses and service connection as provided by the host system |

| Installation Method | Plug-in PCB module inside the drive cabinet; secured by standoffs and designated connectors |

| Dimensions & Weight | Compact plug-in board; typically under 0.5 kg |

Application Fields

You might notice this board most often in heavy-duty ABB drive applications where uptime is critical: metals (rolling mills, coil lines), paper & pulp (winders, coaters), mining & minerals, marine propulsion/auxiliary drives, oil & gas process skids, and water/wastewater aeration or pumping stations. A maintenance supervisor from a steel plant told us they swapped this board during a planned 2‑hour window and avoided a weekend shutdown—exactly the kind of pragmatic win this part is known for.

Advantages & Value

- Compatibility – Built for ABB drive platforms that call for XVC767AE105/3BHB007209R0105; no mechanical rework in most cases.

- Reliability – Stable, repeatable behavior under industrial electrical noise and temperature variations.

- Lower downtime cost – Quick board swap keeps production on schedule; typically no PLC reprogramming if you restore the same parameters.

- Support-ready – Easy to document and service; technicians can back up parameters and verify signals rapidly.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated control cabinet. Maintain adequate airflow and avoid conductive dust.

- Power isolation – Fully isolate and discharge the drive before handling. Follow ESD procedures (ground strap, ESD mat).

- Wiring – Seat all ribbon/backplane connectors firmly; check keying and standoff alignment to prevent stress on the PCB.

- Parameter handling – Back up the drive parameters before removal. After installation, restore and verify firmware/parameter compatibility with your drive revision.

- Routine checks – Periodic visual inspection for discoloration or loose connectors; gently clean with dry air. Review firmware and update only to ABB-approved versions for your system.

Quality & Certifications

- Standards – Typically supplied as part of CE-conforming ABB drive systems; RoHS-compliant manufacturing is standard for modern ABB electronics.

- Quality system – Manufactured under ABB’s ISO 9001 quality management framework.

- Warranty – 365-day warranty coverage as stated above.

If you’re replacing an existing board, sharing the drive type and current firmware/parameter set helps us confirm fit and ship the right revision the first time. One thing I appreciate is how straightforward this unit is to commission when that information is available—it saves a service call in many cases.

Reviews

There are no reviews yet.