Description

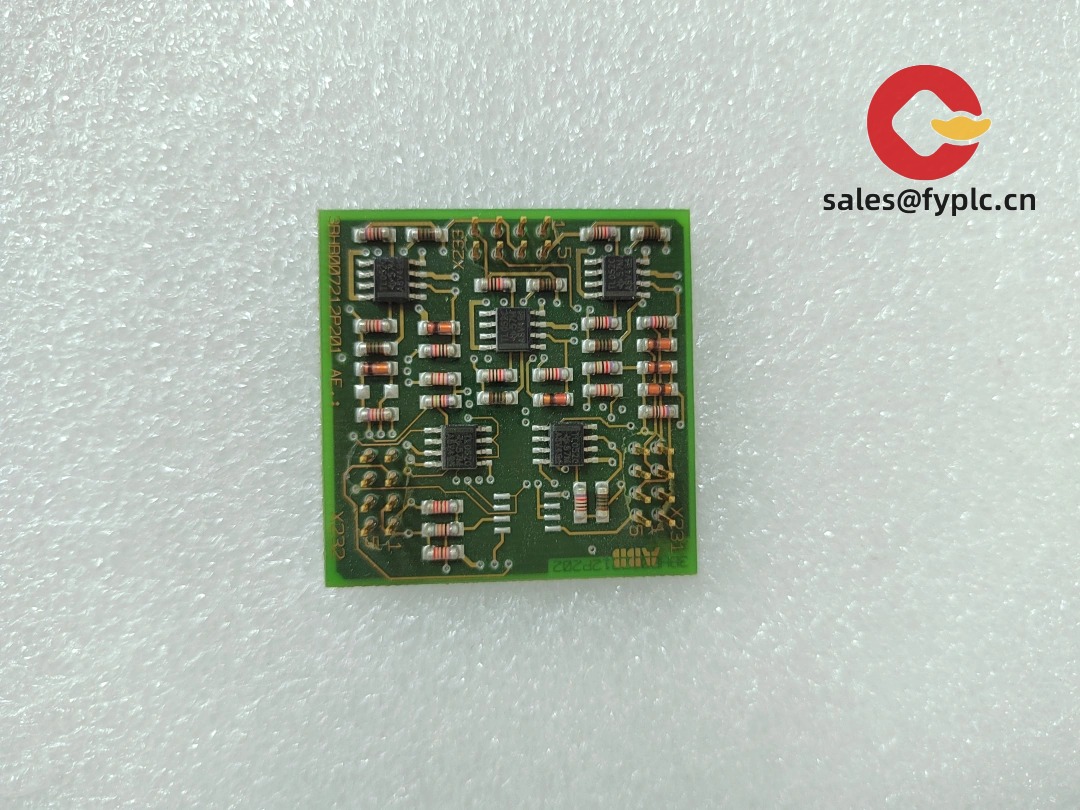

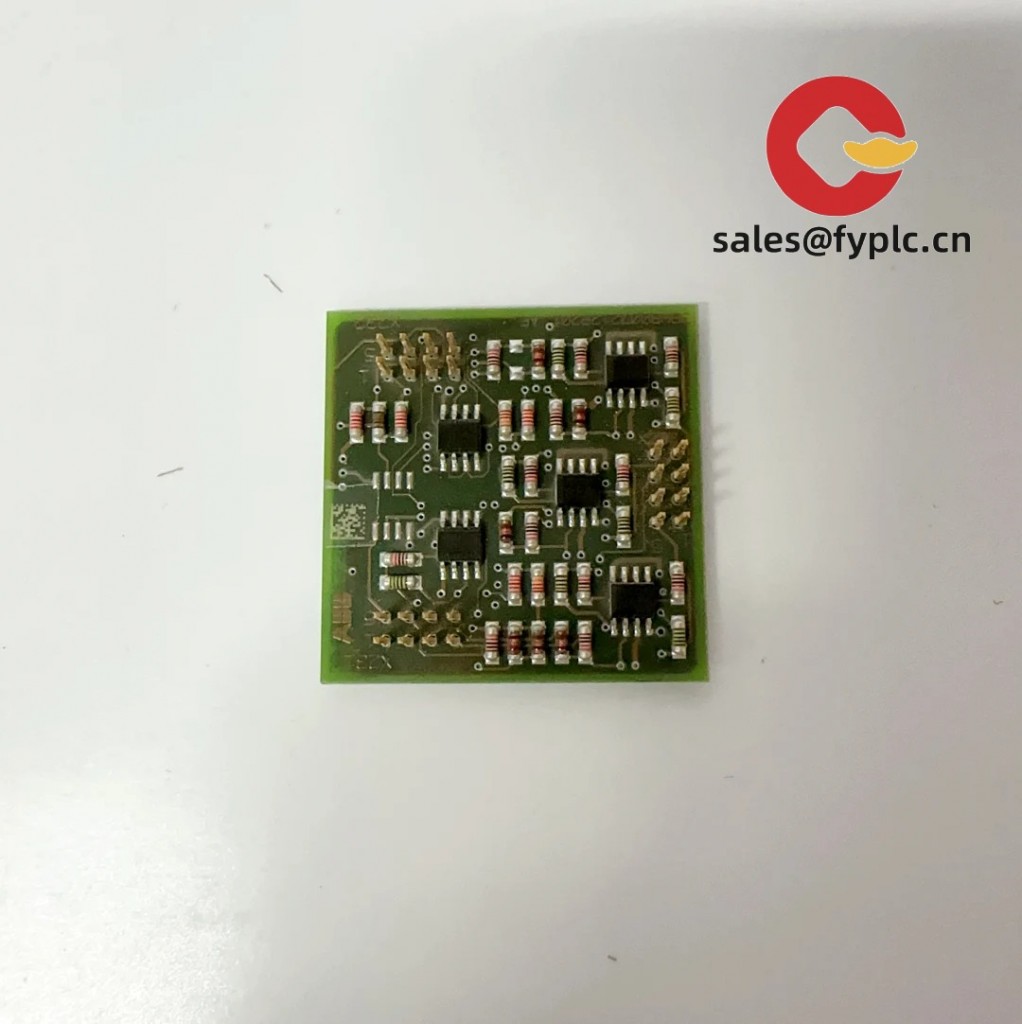

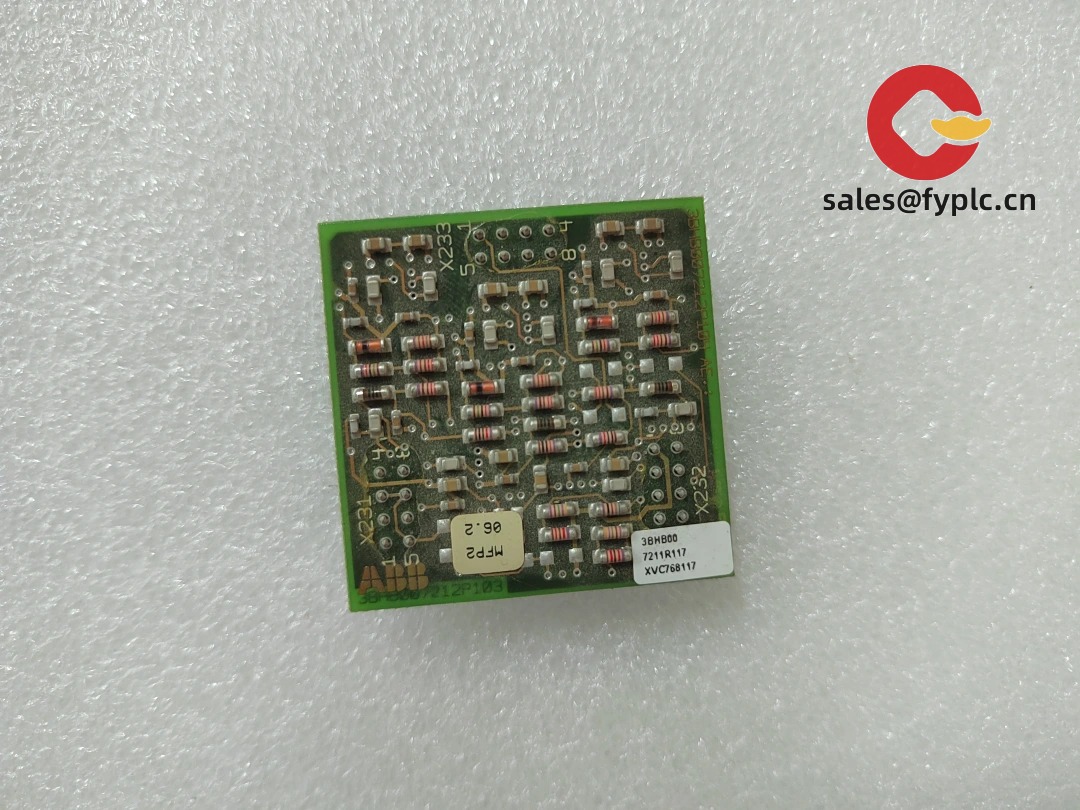

ABB XVC768117 (3BHB007211R117) Gate Driver Unit – Reliable IGCT/IGBT drive control module for ABB medium-voltage drives

The ABB XVC768117, ordered under part number 3BHB007211R117, is a gate driver/control board typically used in ABB medium-voltage drive power stacks. From my experience, it’s the kind of module maintenance teams keep on the shelf because it drops in quickly, restores pulse triggering to the power devices, and plays nicely with the drive’s existing fiber-optic command links.

You might notice that many sites list it simply as a “gate unit” — in many cases it’s installed in ACS-series MV drive stacks where IGCT/IGBT triggering and health feedback need to be rock-solid.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Dedicated gate drive control – Provides pulse triggering and monitoring for power semiconductors (IGCT/IGBT) within ABB MV drive stacks.

- Fiber‑optic command links – Optical triggering and feedback reduce noise susceptibility in high-EMI environments.

- 24 VDC auxiliary power – Typically powered from the drive’s internal 24 VDC bus, making replacement straightforward for field technicians.

- Drive-integrated diagnostics – Status LEDs and feedback channels help pinpoint gating faults or loss of command quickly.

- Form‑fit replacement – In most cases, fits directly in place of the same code board with minimal adjustments; good for rapid downtime recovery.

- Industrial robustness – Designed for cabinet installation near high-power stacks where thermal and electrical stress are present.

Technical Specifications

| Item | Specification |

|---|---|

| Brand / Model | ABB XVC768117 – 3BHB007211R117 |

| HS Code | 8538900000 (Parts for switchgear, control or protection equipment) |

| Power Requirements | Typically 24 VDC auxiliary supply from the drive (low power consumption) |

| Operating Temperature | Typically 0 to +55 °C within a ventilated control cabinet (non‑condensing) |

| Signal Input/Output Types | Fiber‑optic gate commands and status feedback; discrete status/enable lines as per drive design |

| Communication Interfaces | Optical links to the control unit; local status LEDs; service identification via board label |

| Installation Method | Fixed inside the drive’s power stack/cabinet; screw-mounted with keyed connectors and fiber ports |

| Typical Use | Gate driving and monitoring for ABB MV drive modules (verify against your drive type/serial number) |

Application Fields

Commonly deployed in medium‑voltage VFD systems handling high‑power motors. I typically see it in:

- Oil & gas — large compressors and reinjection pumps

- Metals and mining — mills, hoists, fans, and conveyors

- Cement — kilns, ID/FD fans, and clinker coolers

- Power & utilities — boiler feed pumps, cooling tower fans

- Marine — propulsion auxiliaries and big HVAC drives

One maintenance lead at a cement plant told me the spare XVC board “saved a weekend outage” because it slotted in, fiber leads clicked on, and the drive came back with clean gating signals right away.

Advantages & Value

- Reliability – Stable gate pulses and clear fault feedback reduce nuisance trips and investigation time.

- Compatibility – Designed for ABB MV drive stacks using optical links; in many cases a direct board swap with no wiring changes.

- Lower downtime – Fast replacement and simple commissioning save labor and lost production hours.

- Technical support – Assistance with part identification by drive type, serial number, and board code to avoid mismatches.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated enclosure. Keep ambient typically within 0…55 °C and avoid condensation.

- ESD and safety – Power down, discharge DC link, follow lockout/tagout. Use ESD protection when handling the board.

- Fiber‑optic care – Clean connectors before mating, respect bend radius, and ensure TX/RX orientation matches the original.

- Wiring – Use the same keyed connectors; verify 24 VDC auxiliary supply and grounding points as per the drive manual.

- Version matching – It appears that certain drive firmware/board revisions pair together; confirm the code suffix against the existing unit or share your drive nameplate for a quick check.

- Routine checks – Inspect connectors quarterly, confirm LED status during startup, and keep the cabinet dust‑free. Firmware updates are rarely needed on gate units, but follow ABB guidance where applicable.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- CE compliant design; RoHS-compliant materials in most recent builds

- Meets industrial EMC practices when installed as part of the ABB drive system

- Manufacturer warranty support aligned with the 365‑day coverage above

If you can share your drive type, serial number, and the label photo of your current board, I can confirm fitment for XVC768117 (3BHB007211R117) and advise on any companion parts that are typically replaced at the same time (for example, adjacent interface boards or fiber harnesses).

Reviews

There are no reviews yet.