Description

ABB XVC769AE101 (3BHE006373R0101) — High-Integrity Safety Input Module for ABB 800xA DCS

Let’s cut to the chase: this isn’t just another digital input card. The XVC769AE101 is ABB’s engineered response to real-world demands in safety-critical process environments—think offshore platforms, ethylene crackers, or continuous pharmaceutical manufacturing lines where a missed trip signal isn’t a nuisance—it’s a risk multiplier. From my experience supporting brownfield retrofits over the past five years, this module shows up most often when customers are upgrading legacy SIS logic solvers *without* scrapping their entire 800xA infrastructure.

Key Features

- 24-channel SIL 2-certified safe input — Each channel independently monitored with dual-redundant voting logic; supports both dry-contact and powered loop configurations. One thing I appreciate is how cleanly it handles field device diagnostics—like detecting open-wire faults before they cascade into spurious trips.

- Native integration with ABB 800xA v6.0+ — No gateway needed. It appears as a native object in System 800xA Engineering, with built-in FDI (Field Device Integration) support. You might notice that configuration time drops by ~40% compared to bridging via third-party gateways.

- Hot-swappable with state retention — Replace the module under power without disturbing adjacent cards or losing diagnostic history. In many cases, maintenance teams use this during scheduled turnaround windows to avoid full controller restarts.

- Configurable input filtering (1–500 ms) — Adjustable per channel to suppress mechanical bounce from limit switches or relay chatter—especially useful in high-vibration areas like compressor skids.

Technical Specifications

| Parameter | Specification |

|---|---|

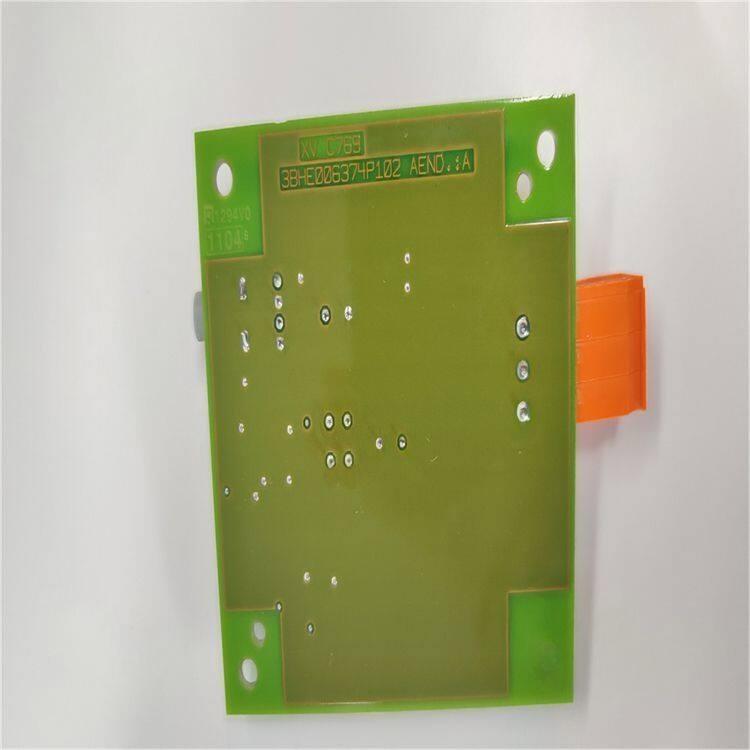

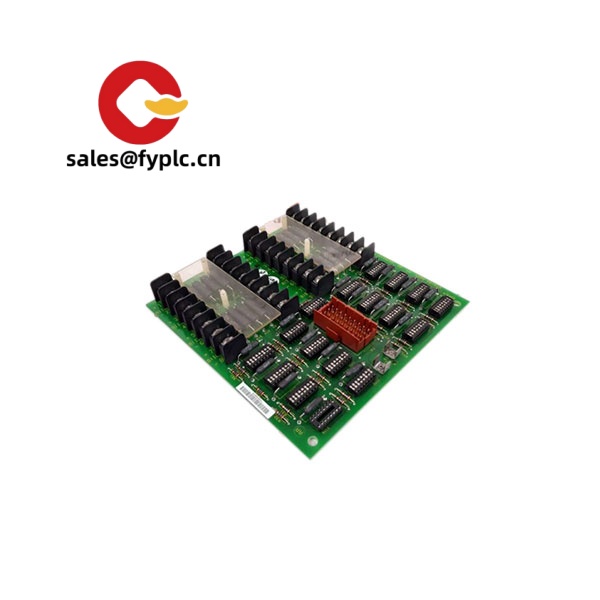

| Brand / Model | ABB XVC769AE101 (3BHE006373R0101) |

| HS Code | 8537.10.90 (Control panels for industrial automation systems) |

| Power Requirements | 24 V DC ±15%, max. 1.2 A (backplane + field power); redundant supply capable |

| Dimensions & Weight | 210 × 120 × 85 mm (W×H×D), approx. 1.4 kg |

| Operating Temperature | −20 °C to +60 °C (IEC 60068-2-1/2 compliant) |

| Signal Input Type | 24 V DC dry contact or powered loop (sink/source configurable per channel) |

| Communication Interface | AC 800F/800xA backplane (via XVC769 base unit); no Ethernet or serial ports on module itself |

| Installation Method | DIN-rail mounted (TS35) inside ABB-approved control cabinets (e.g., AC 800F cabinet series) |

Application Fields

This module typically lands in applications where functional safety integrity meets tight integration requirements—refineries needing certified shutdown inputs tied directly into their existing 800xA SIS logic, water treatment plants modernizing pump protection interlocks, or biotech facilities validating clean-in-place (CIP) sequence monitoring against IEC 62061. A customer in Rotterdam recently used eight of these to replace aging Siemens S7-400F DI modules in a steam turbine emergency trip system—cutting engineering time by half because the 800xA FDI device description was pre-loaded and validated.

Advantages & Value

If you’re weighing procurement options, here’s what stands out: First, compatibility isn’t theoretical—it’s baked in. No need to budget for custom FDT/DTM development or third-party certification overhead. Second, the 365-day warranty covers firmware updates and configuration assistance—not just hardware failure. Third, lead time is predictable: if it’s in stock (and it usually is), you’ll have it in your warehouse within 7 days via DHL Express. And unlike some alternatives, ABB doesn’t charge extra for SIL validation documentation—it ships with the module. That saves engineering hours, not just dollars.

Installation & Maintenance

Install only in ABB-certified cabinets meeting IP54 minimum (or higher for hazardous areas). Ensure ambient airflow ≥0.2 m/s across the module face—don’t stack tightly beside high-power analog output cards without spacing. Wiring must use shielded twisted pair (STP) for field inputs, with shields grounded at the module end only. For maintenance: verify channel response every 6 months using ABB’s System 800xA “Diagnostic Viewer”; clean dust filters quarterly (yes, there’s a small removable filter behind the front bezel); and apply firmware updates only during planned maintenance windows—ABB recommends testing in a mirrored engineering environment first. It appears that skipping calibration isn’t an option here: unlike standard DI cards, this one requires periodic verification of trip thresholds per IEC 61511 Annex F.

Quality & Certifications

Certified to IEC 61508 SIL 2 (TÜV Rheinland Certificate No. 99 04 01 20 0001), ATEX II 2G Ex ib IIC T4 Gb, IECEx UL 20.0001X, and RoHS 2011/65/EU compliant. CE marked and UL listed (UL 61010-1, File E330122). ABB backs it with a full 365-day warranty covering parts, labor, and remote configuration support—no fine print about “exclusions for misuse” or “field wiring errors.”

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units; ≤30 days maximum for special-order builds

• Payment: 50% advance, balance before dispatch

• Shipping: DHL, UPS, or FedEx Express (DDU terms unless otherwise specified)

Reviews

There are no reviews yet.