Description

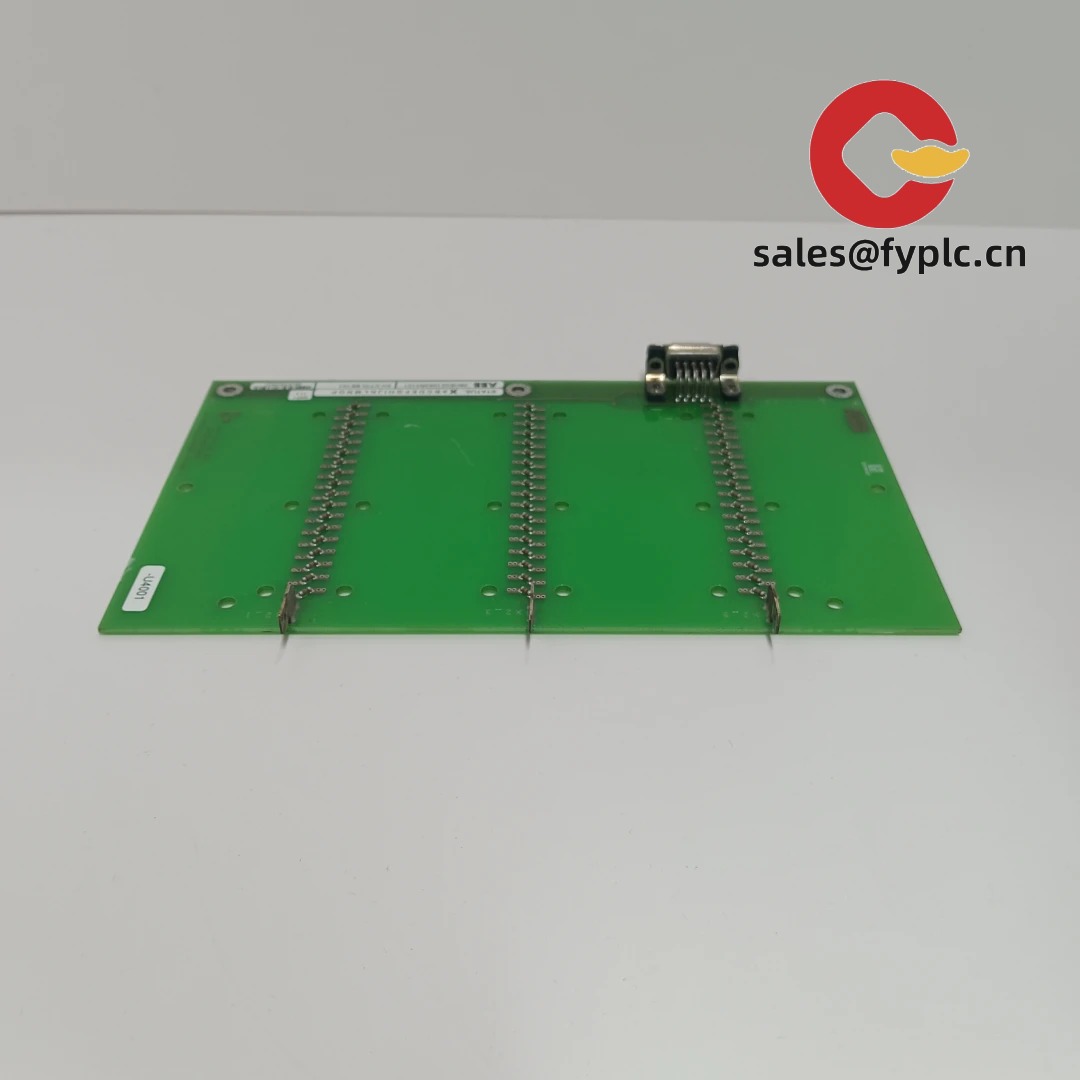

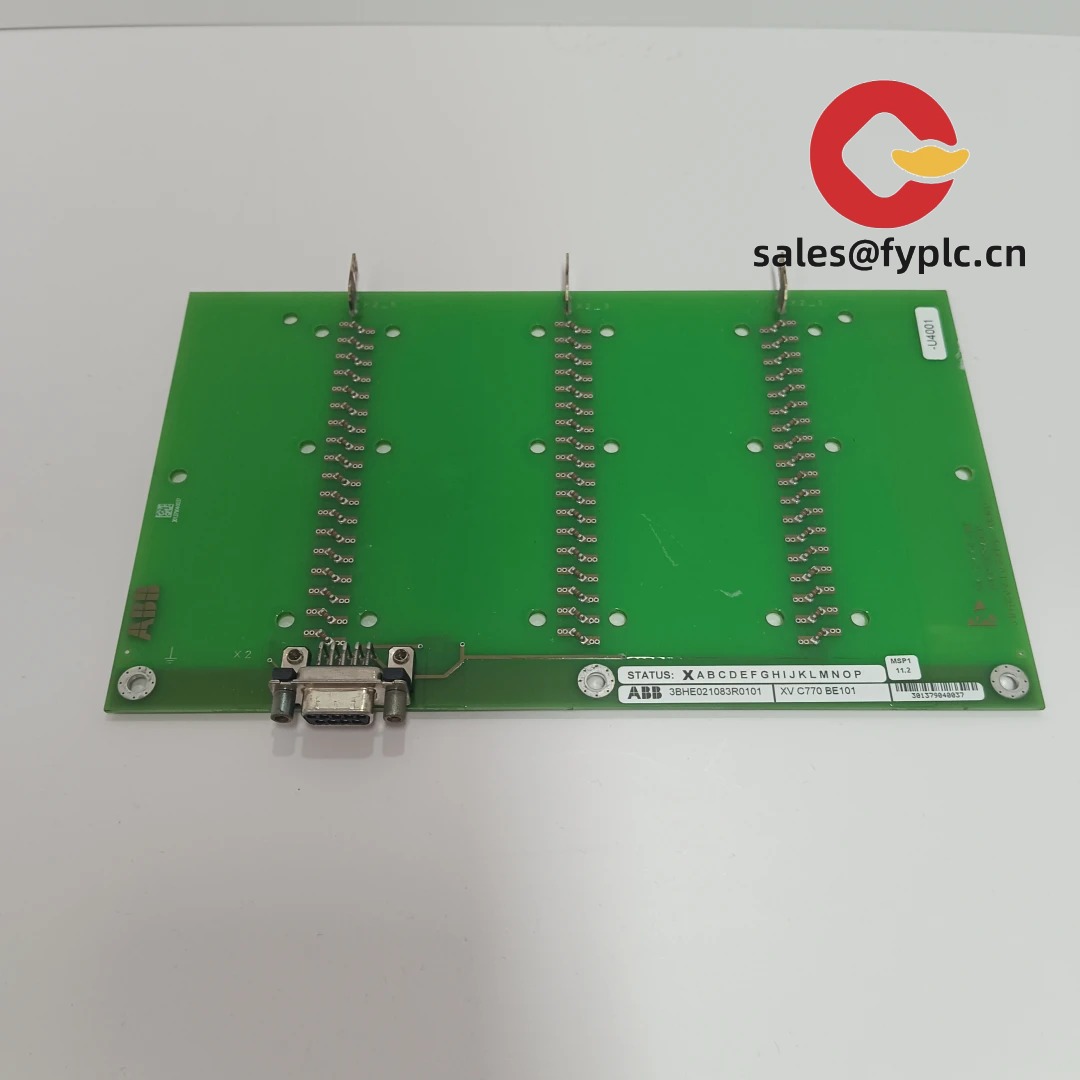

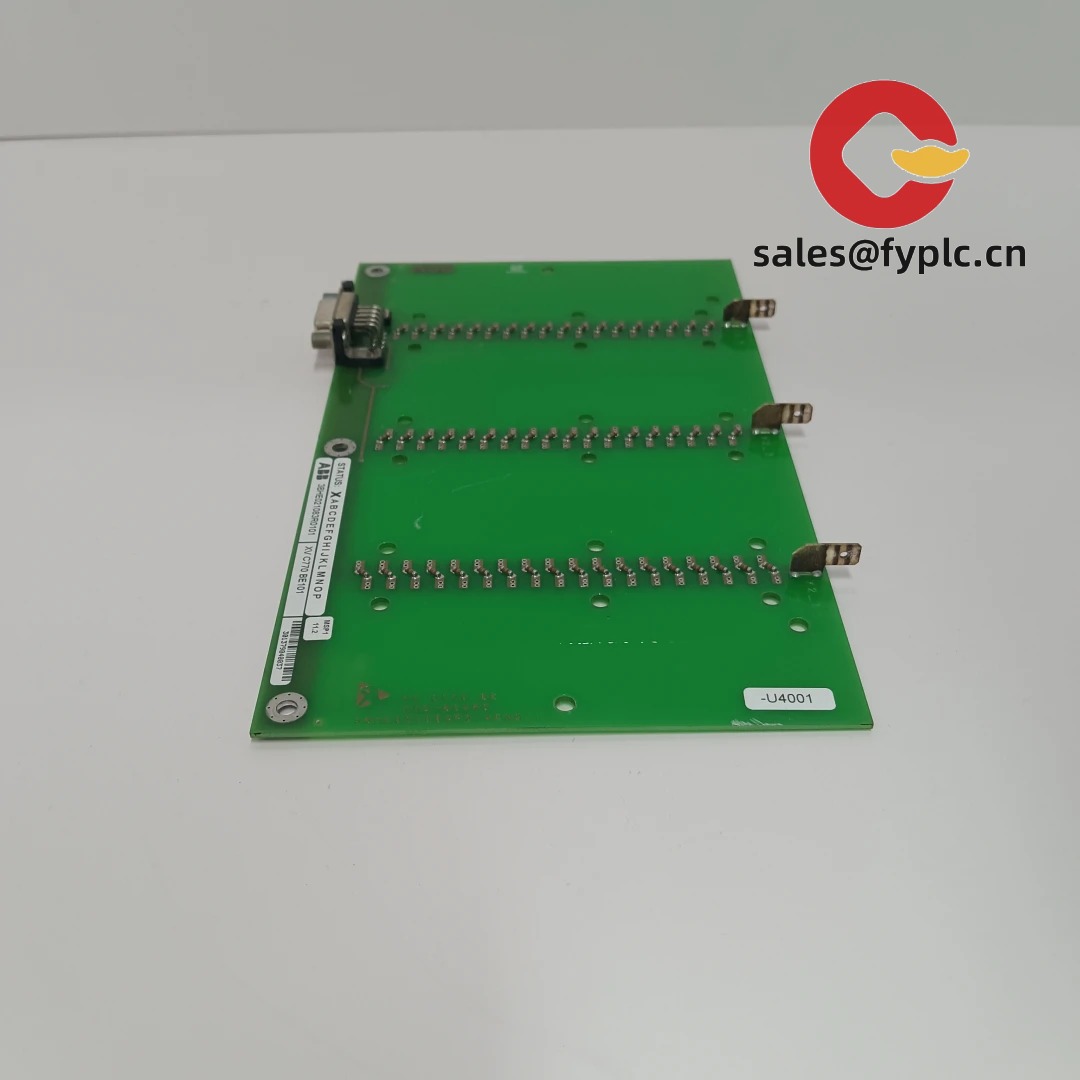

ABB XVC770BE101 (3BHE021083R0101) – Industrial Controller CPU for ABB DCS/Drive Systems

The ABB XVC770BE101, part number 3BHE021083R0101, is a robust industrial controller CPU used widely in ABB process automation and power applications. From my experience, it’s typically chosen as a drop-in replacement to keep legacy ABB systems running 24/7 without disrupting the installed I/O or fieldbus network. If you’re maintaining an existing ABB platform in a power plant, metals line, paper mill, or a midstream facility, this unit is the kind of spare that seems to pay for itself in avoided downtime.

Order Placement Process and Guarantees

- Warranty: 365 days coverage.

- Delivery: 1 week if in stock; no more than one month at the latest.

- Payment: 50% advance payment; full payment prior to delivery.

- Express options: FedEx, UPS, DHL.

One thing I appreciate is how straightforward the process is for urgent MRO needs—once we confirm availability, the logistics move fast. You might notice that documentation and basic power-up checks are included so your site team can install with confidence.

Key Features

- Controller-grade CPU module – Designed for continuous operation in ABB DCS/drive and excitation environments.

- Seamless replacement – Typically drop-in compatible with existing cabinets and wiring, minimizing commissioning time.

- Industrial power input – 24 VDC nominal supply commonly used across ABB cabinets for simple integration.

- Standard interfaces – Ethernet and serial ports for system networking; fieldbus via add-on/connected modules.

- No onboard I/O – Works with remote I/O (e.g., S800 I/O or PROFIBUS/Modbus remote I/O), which keeps cabinet layouts unchanged.

- Service-friendly – Modular design makes field replacement, backups, and firmware servicing straightforward.

A maintenance engineer at a combined-cycle plant told me they swapped in this unit within a scheduled 2-hour window—no panel rewiring, and the process line came back with the same configuration image.

Technical Specifications

Note: Specific connector layouts and firmware package depend on the exact hardware revision. We can help verify against your current system tag list and photos before shipment.

Application Fields

- Power generation and excitation control, where continuous duty and predictable switchover are crucial.

- Metals and rolling mills that rely on deterministic control and fieldbus I/O islands.

- Pulp & paper process lines using ABB DCS architectures with remote I/O segments.

- Oil & gas (midstream/downstream) control cabinets requiring Ethernet and serial integration.

- Marine and utilities cabinets with 24 VDC distribution and tight space constraints.

Advantages & Value

- Reliability: Built for 24/7 operation; proven mean-time-between-failure in many installed bases.

- Compatibility: Works with existing ABB cabinets, I/O networks, and engineering tools—reduces revalidation effort.

- Cost Control: Extends system life without a full migration; fewer engineering hours and minimal change control.

- Support: Pre‑shipment testing and documentation; post‑delivery assistance for basic start-up checks.

Installation & Maintenance

- Cabinet standards: Install in a clean, ventilated control cabinet. Maintain clearance for airflow; avoid heat sources above the controller.

- Power & grounding: Use a stabilized 24 VDC feed with proper grounding. Follow ABB wiring diagrams for shield terminations and earth bonding.

- Networking: Keep Ethernet cables industrial-rated; segregate from high-voltage runs. For serial/fieldbus, respect segment lengths and termination rules.

- ESD care: Handle modules with ESD protection; power down and isolate before insertion/removal.

- Routine maintenance: Back up configuration/firmware images; check connectors annually; light dust cleaning with dry air; firmware updates when validated by site standards.

- Spare strategy: In most cases, one on-the-shelf spare per unit operation is a practical balance between risk and carrying cost.

Quality & Certifications

- Manufactured to ABB’s quality system (ISO 9001). Units are typically CE-marked and RoHS-compliant; many installations also require UL/cUL—available by hardware revision.

- Manufacturer practice: industrial-grade components and firmware traceability by part number and revision.

- Warranty: 365 days from our side; extended coverage can be discussed for critical assets.

Related/Supporting Components (typical pairings)

- 24 VDC industrial power supplies with redundancy (for higher availability).

- Remote I/O subsystems (e.g., PROFIBUS or Modbus I/O racks) that the controller supervises.

- Industrial Ethernet switches with DIN‑rail mounting and managed features for DCS segmentation.

- Panel HMIs or industrial PCs for local visualization and operator access.

If you can share your existing controller label and a quick photo of the cabinet bay, we’ll confirm interface compatibility and ship the exact XVC770BE101 variant you need without guesswork.

Reviews

There are no reviews yet.