Description

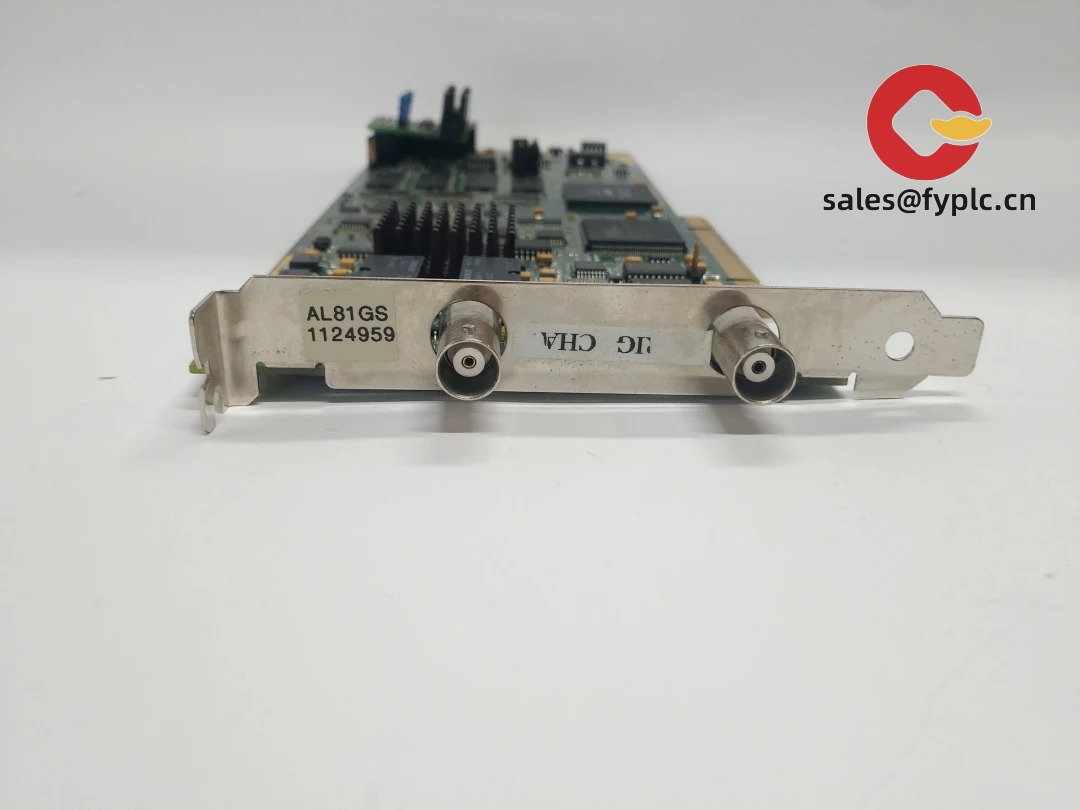

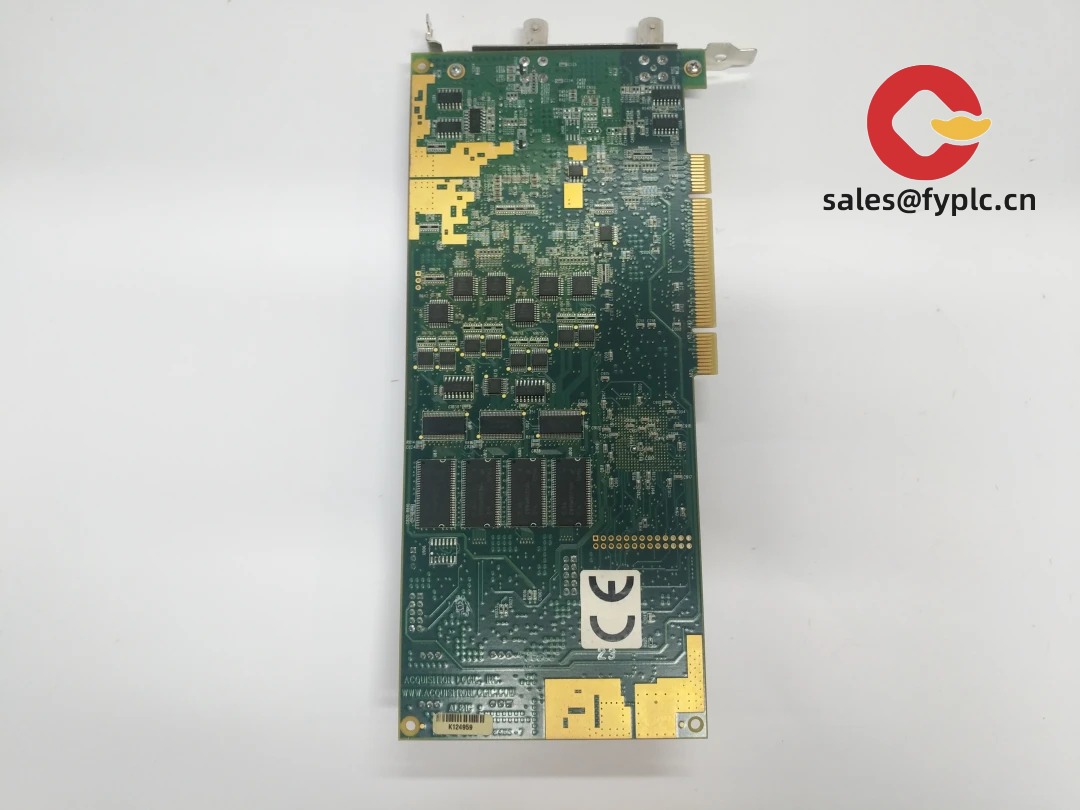

ACQUISITIONLOGI AL81G – 8‑Channel Analog Input Module for Reliable Industrial Data Acquisition

The ACQUISITIONLOGI AL81G is designed for straightforward, stable analog signal acquisition on the factory floor. It typically fits right into DIN-rail cabinets and speaks Modbus RTU over RS‑485, so integrating it with existing PLCs, SCADA, or data loggers is usually painless. From my experience, plants use it to pull clean voltage or 4–20 mA readings from sensors, then hand them off to higher-level controllers for trending and alarms.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 8 analog input channels – Ideal for multi-point monitoring on pumps, compressors, or process lines without overbuilding the cabinet.

- Typical input ranges – ±10 V, 0–10 V, 0–5 V; 4–20 mA supported via external shunt resistor. This covers most plant sensors.

- Industrial RS‑485 (Modbus RTU) – You can tie it into existing PLCs/SCADA; addressing and baud rate are usually simple to set.

- Wide 9–36 VDC power input – Plays nicely with standard control power rails; reverse-polarity protection is commonly included.

- DIN-rail mounting – Compact footprint for tight cabinets; you might notice how the wiring stays clean even in mixed-signal panels.

- Rugged operating range – Built for plant environments; it typically holds up well to electrical noise when wired properly.

Technical Specifications

| Brand / Model | ACQUISITIONLOGI / AL81G |

| HS Code | 8537.10 (Boards/panels for electric control, for voltage ≤1000 V) |

| Power Requirements | 9–36 VDC input; approx. 3 W typical |

| Dimensions & Weight | Approx. 120 × 75 × 35 mm; ~200 g |

| Operating Temperature | -20 to +60 °C (industrial, typical) |

| Signal Input/Output Types | 8 × Analog Inputs (±10 V / 0–10 V / 0–5 V; 4–20 mA via shunt); 16‑bit resolution typical |

| Communication Interfaces | RS‑485 (Modbus RTU); configurable address and baud rate |

| Installation Method | DIN‑rail (EN 60715) or panel mounting |

Application Fields

Plants typically deploy the AL81G in process monitoring, utilities metering, and light manufacturing cells where reliable analog capture matters more than complex on-board control. Common scenarios:

- Packaging lines – reading load cells (via transmitter), analog temperature, and drive references for quality tracking.

- Water & wastewater – grabbing 4–20 mA levels/flows and pushing them to SCADA over RS‑485 in distributed stations.

- HVAC & building automation – collecting chilled water temperatures and valve position feedback for energy dashboards.

- Utilities monitoring – voltage and sensor taps in power cabinets for trend analysis and predictive maintenance.

A maintenance supervisor told us, “We swapped in the AL81G for a legacy I/O block and kept the same Modbus map with minor tweaks. No surprises on noise immunity once we grounded the shield correctly.”

Advantages & Value

- Compatibility-first – Modbus RTU makes it straightforward to drop into existing PLC/SCADA networks without rewriting the stack.

- Cost-effective channel density – 8 AI in a compact module helps reduce cabinet real estate and wiring time.

- Reliable in noisy panels – With proper shielding and grounding, it typically delivers stable readings next to VFDs and contactors.

- Support and availability – Fast lead times on stocked units and clear setup guidance cut commissioning risk.

Installation & Maintenance

- Cabinet & environment – Mount on EN 60715 DIN‑rail in a ventilated enclosure; leave space for airflow; avoid direct heat sources and moisture.

- Wiring best practices – Use shielded twisted pairs for analog lines; ground one end of the shield; keep analog separated from high‑voltage and motor cables.

- Power & protection – 24 VDC supply is typical; add a dedicated fuse and surge protection on RS‑485 where transients are expected.

- Safety – De‑energize before wiring; verify sensor ranges (e.g., 0–10 V vs 4–20 mA) to avoid scaling errors.

- Routine maintenance – Periodically tighten terminals, clean dust with dry air, and re‑verify calibration annually; update firmware when available to improve stability.

Quality & Certifications

The AL81G is built for industrial environments and, in many cases, is supplied to projects requiring CE and RoHS conformity. UL listing may depend on the specific project or region. If you need formal certificates, we can share the dossier for the delivered lot. Manufacturer warranty coverage is 365 days as stated above.

Reviews

There are no reviews yet.