Description

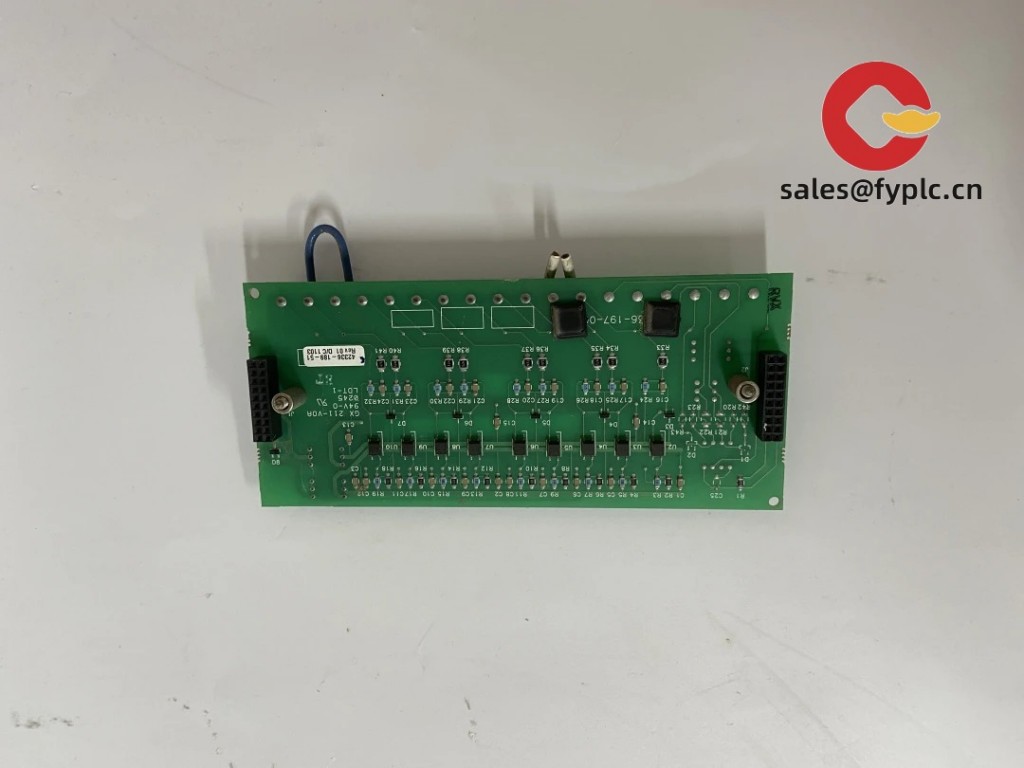

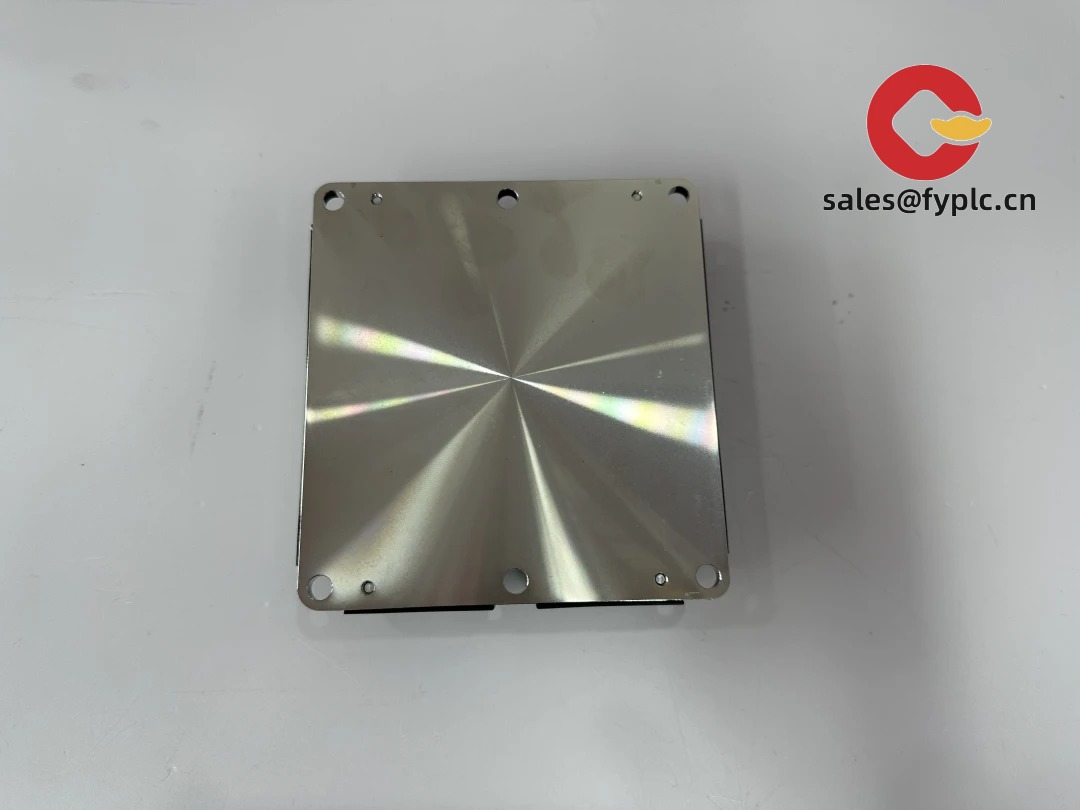

Allen‑Bradley 1336‑QOUT‑SP23A (with FZ1200R16KF4) – Output IGBT Power Stack Assembly for 1336 FORCE/PLUS High‑HP Drives

The A‑B 1336‑QOUT‑SP23A is an output power stack assembly for Bulletin 1336 drives, built around high‑current IGBT modules (this variant incorporates Infineon FZ1200R16KF4 devices and the 74101‑177‑52 bus/heatsink geometry). From my experience, this is the go‑to spare when the drive’s output section has failed—shorted transistors, cracked modules, or thermal damage. You swap the complete stack, land the DC bus and motor leads, connect the gate/feedback harnesses, and—if the control section is healthy—the cabinet typically returns to service without re‑engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification, heatsink/module integrity, and packing in ESD‑safe, shock‑resistant materials

Key Features

- Drop‑in output stack – Matches the 1336 frame mechanics and clearances; reduces fit‑up time during outages.

- High‑current IGBTs – Uses Infineon FZ1200R16KF4 modules for tough, high‑HP applications (fans, extruders, large pumps).

- Factory busbar layout – Correct creepage/clearance and laminated bus reduce stray inductance and stress at switching edges.

- Thermal path optimized – Heatsink, interface pads/compound, and thermal sensor routing set up for continuous duty.

- Service‑friendly – Clearly keyed gate/feedback connectors and defined torque specs make commissioning predictable.

Technical Specifications

| Brand / Model | Allen‑Bradley 1336‑QOUT‑SP23A (contains FZ1200R16KF4 IGBT modules; 74101‑177‑52 assembly) |

| Function | Output IGBT power stack assembly for Bulletin 1336 FORCE/PLUS high‑HP drives |

| HS Code | 8504.90 – Parts of static converters (country classification may vary) |

| Power Requirements | Passive assembly; supplied by the drive DC bus and gate driver rails |

| Signal/Power Interfaces | DC+ / DC− bus bars; U/V/W motor outputs; gate/NTC feedback harness to driver board (variant‑dependent) |

| Communication | None (all control via gate driver connections) |

| Dimensions & Weight (approx.) | Assembly scale for high‑HP frames; ~300–400 × 220–300 × 120 mm; ~8–15 kg |

| Operating Environment | Inside drive enclosure; typically 0…+40 °C; non‑condensing; forced airflow required |

| Installation Method | Bolt‑in replacement on standoffs; torque bus bars to spec; connect gate/NTC harnesses; verify isolation clearances |

Application Fields

Typical use cases when an output section failure has a 1336 drive down:

- Metals & converting lines – high‑inertia loads and frequent reversals.

- Pulp & paper – section drives with 24/7 duty and elevated ambient temperatures.

- Water & wastewater – large blowers and pump trains where uptime is critical.

- Mining/material handling – conveyors and crushers with heavy overload cycles.

One maintenance lead told me, “We dropped in the SP23A stack, set bus bar torque, reconnected the gate harness, and the motor phased clean on first start.” That’s been the pattern in most cases when the control board and cooling fans are healthy.

Advantages & Value

- Reliability – Proven IGBT devices and factory bus layout for stable switching at high current.

- Compatibility – Mechanical/electrical fit for the intended 1336 frames; preserves cabinet design.

- Downtime reduction – Complete stack replacement is, in many cases, faster than module‑level repairs.

- Support – We can help confirm frame compatibility, torque specs, and thermal compound guidance before your outage.

- Lifecycle savings – Extends installed‑base drives and defers costly platform migration.

Installation & Maintenance

- Safety/LOTO: Lock out mains; verify DC bus is fully discharged; use HV gloves and insulated tools.

- Mechanical fit: Inspect standoffs and insulating barriers; maintain creepage/clearance; replace damaged insulators.

- Electrical joints: Clean bus interfaces; apply approved thermal/EMC materials if specified; torque per manual.

- Gate wiring: Route harnesses away from power conductors; verify keyed connectors; check NTC/thermal feedback readouts.

- Cooling: Confirm fan operation and airflow path; re‑seal ducts; trend heatsink temperature on first runs.

- Post‑start checks: Light‑load run, then step‑load; monitor phase current balance, switching events, and fault logs.

Quality & Certifications

- Built to Rockwell Automation quality practices (ISO 9001 aligned manufacturing).

- System CE/UL compliance is maintained at the drive level; this is a spare converter assembly.

- RoHS status depends on build/lot; we can confirm by part/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.