Description

Allen‑Bradley 1756-A7_B – ControlLogix 7‑Slot Chassis (Series B) for Compact, Reliable PLC Racks

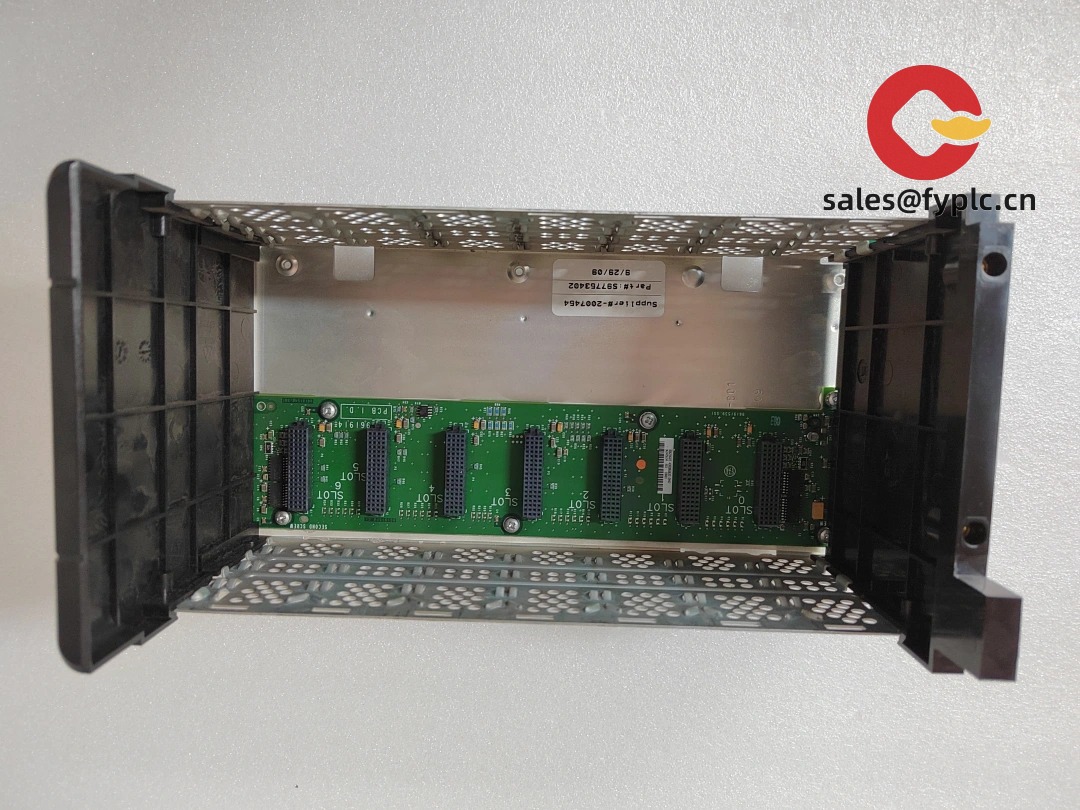

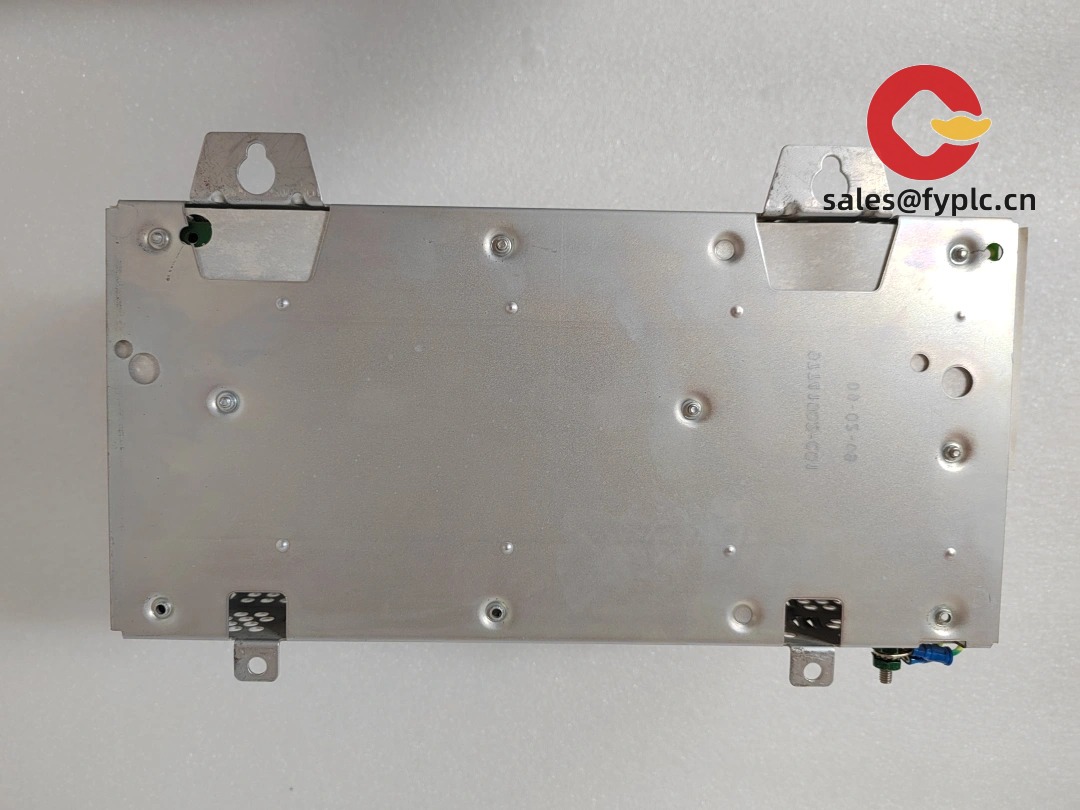

The Allen‑Bradley 1756-A7_B is a ControlLogix 7‑slot chassis, Series B. It provides the backplane and mechanics to host a mid‑size ControlLogix rack—controllers, communications, and I/O modules—without giving up cabinet space you might need for power or marshalling. From my experience, the 7‑slot format hits a sweet spot for OEM skids and plant expansions: enough capacity to grow, yet still easy to fit and cool in standard enclosures. You might notice the familiar left‑side power supply mount and the robust module retention latches; swaps during short maintenance windows are typically very straightforward.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and mounting check; ESD‑safe, shock‑resistant packing

Key Features

- 7‑slot ControlLogix backplane – Fits controllers, comm modules, and I/O for medium racks without oversizing the cabinet.

- Series B mechanics – Improved robustness and module retention; typically reduces vibration‑related nuisances.

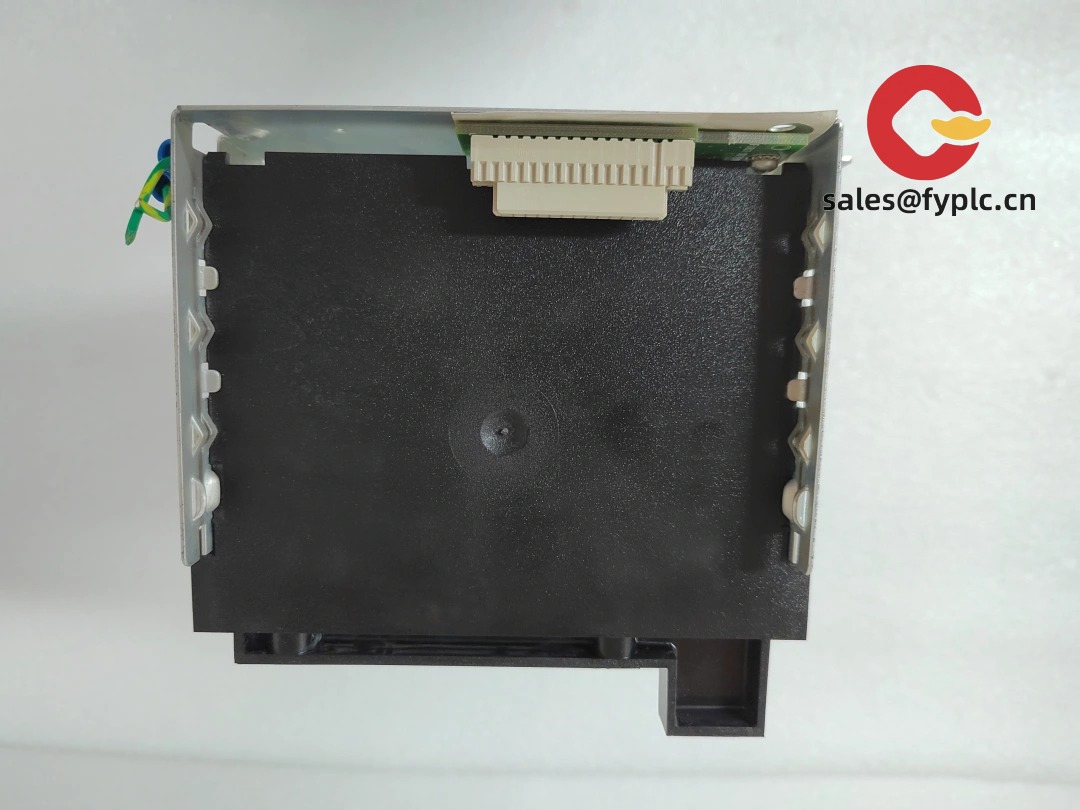

- Left‑mounted power supply – Accepts 1756‑PA/‑PB power supplies (AC or DC); clean, service‑friendly wiring on the chassis left end.

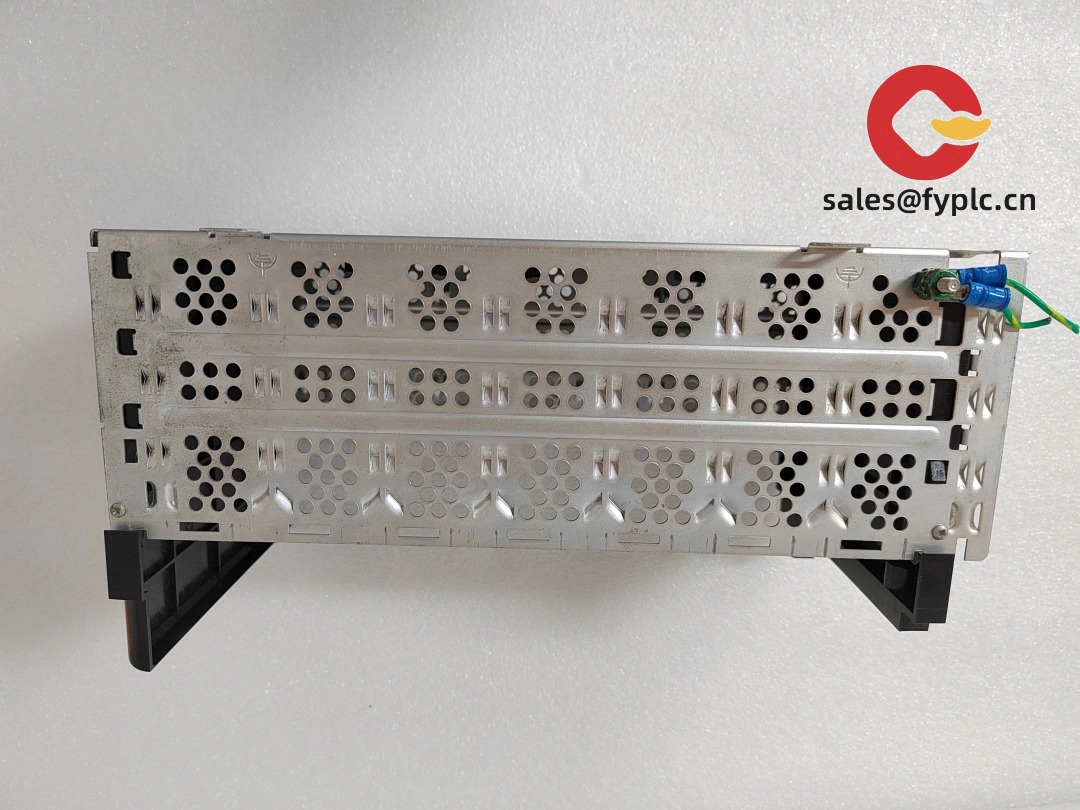

- Grounding and shield tie points – Provides a solid chassis bond to help control noise in mixed analog/digital panels.

- Tool‑less module latching – Fast insertion and extraction; from my experience it keeps outage windows tight and predictable.

- Wide module compatibility – Designed for the ControlLogix family (subject to Rockwell’s compatibility matrix and firmware pairing).

Technical Specifications

| Brand / Model | Allen‑Bradley 1756-A7_B (ControlLogix, Series B) |

| System Family | ControlLogix 7‑slot chassis and backplane |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment |

| Power Requirements | Powered by left‑side 1756 power supply (e.g., 1756‑PA72/‑PA75 AC, 1756‑PB72/‑PB75 DC); the chassis itself has no separate input |

| Slots | 7 module slots on the 1756 backplane (controller, comms, I/O, specialty) |

| Signal I/O Types | Provided by installed 1756 modules; chassis provides backplane only (no field terminals) |

| Communication Interfaces | Via installed comm modules (e.g., EtherNet/IP, ControlNet, DeviceNet); chassis itself has no external ports |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing), per Rockwell guidance |

| Installation Method | Panel mounting inside a grounded enclosure; 1756 power supply mounts to the chassis left end |

Application Fields

You’ll typically see the 1756‑A7_B wherever a compact, expandable ControlLogix rack makes sense:

- OEM skids and process packages – mid‑size racks with room for a controller, EtherNet/IP, and a few I/O slices.

- Brownfield panel upgrades – swap a legacy PLC while preserving cabinet space and wiring routes.

- Utilities and water – reliable backplane for distributed I/O plus networking in compact MCC sections.

- F&B and life sciences – validated enclosures where tidy wiring and fast module service matter.

A panel builder told me recently, “Seven slots covered our CPU, two networks, and four I/O cards—no need to upsize the cabinet.” That’s been a common pattern with Series B chassis in tight spaces.

Advantages & Value

- Reliability – Robust backplane and module retention for 24/7 operation.

- Compatibility – Works with ControlLogix controllers and modules (check Rockwell’s compatibility notes for specific pairings).

- Cost control – Right‑sized slot count avoids paying for unused rack capacity.

- Serviceability – Tool‑less module handling and a clean left‑side power interface shorten maintenance windows.

- Scalability – Easy to standardize across lines; add or shuffle modules as the project grows.

Installation & Maintenance

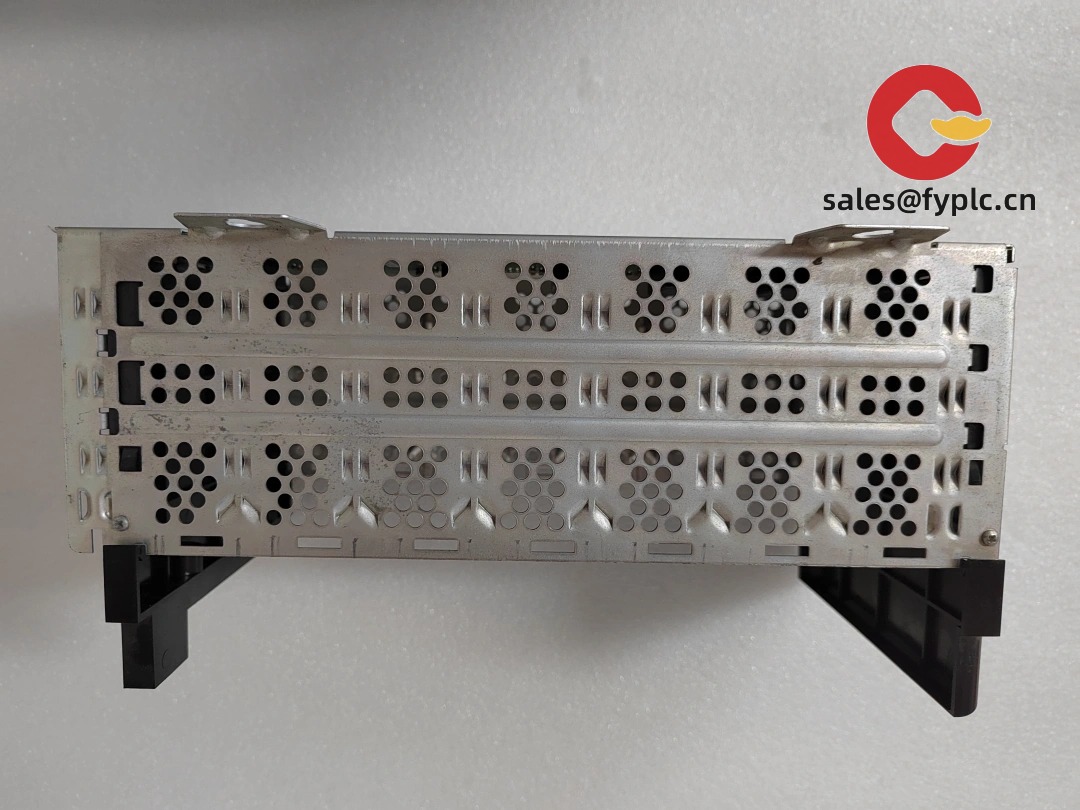

- Cabinet & grounding: Mount in a clean, ventilated enclosure; bond the chassis to panel ground; maintain clear airflow above/below.

- Powering: Use a compatible 1756 power supply on the left end; budget backplane load per Rockwell’s power sizing guidance.

- Wiring & EMC: Route low‑level signals away from VFD leads; maintain shield continuity at the panel side.

- Module handling: De‑energize when practical; use ESD precautions; seat modules fully until the latches click.

- Labeling & docs: Keep slot addresses and module catalog numbers on the door; it typically cuts troubleshooting time in half.

- Routine care: Periodic dust removal and quick re‑torque of mounting hardware; review diagnostics in the controller during PMs.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE marking and UL/cUL listing apply at the system/module level when assembled per Rockwell instructions.

- RoHS compliance depends on series/lot; we can confirm by part/serial if required.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.