Description

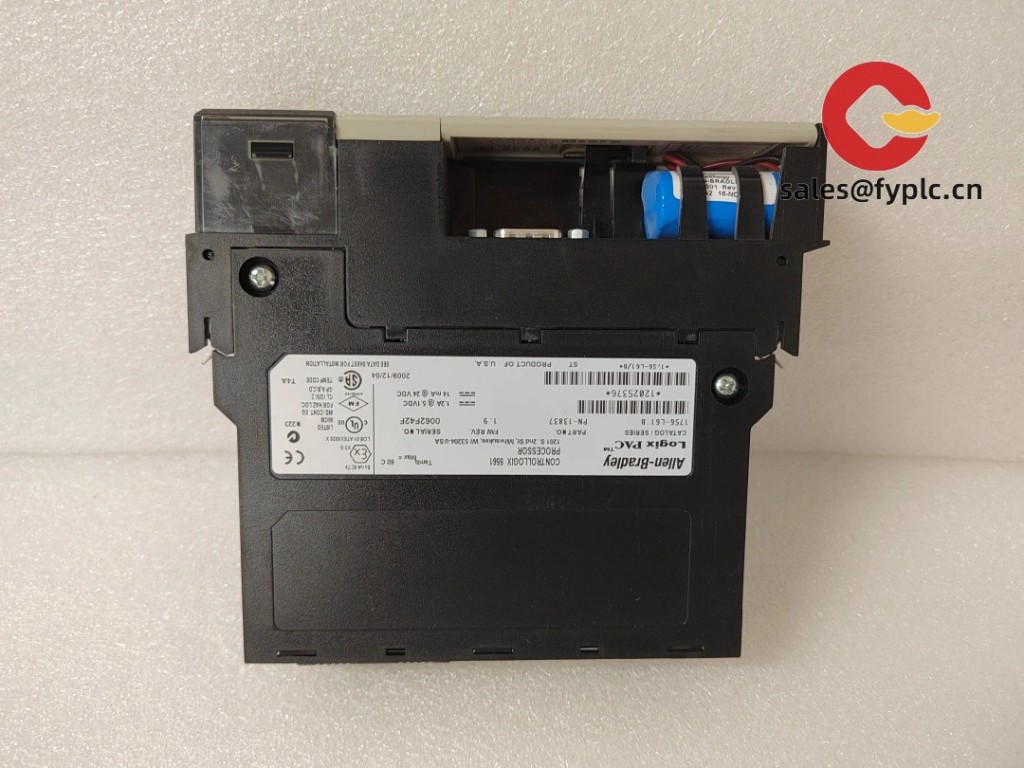

Allen‑Bradley 1756-ENBTA – ControlLogix EtherNet/IP Bridge (commonly the ENBT Series A variant) for PLC Networking

The A‑B 1756-ENBTA is an EtherNet/IP communication bridge for ControlLogix racks. In practical terms, it links your 1756 backplane to plant Ethernet for I/O, HMI/SCADA, and peer controllers. From my experience, the “ENBTA” designation typically corresponds to the 1756‑ENBT Series A hardware, which many plants still run reliably day in and day out. You might notice the straightforward single‑port layout and clear status LEDs—addressing via BootP/DHCP or a static IP is fast, and health checks are pretty predictable during short outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification, port integrity check; ESD‑safe, shock‑resistant packing

Key Features

- EtherNet/IP backplane bridge – Connects ControlLogix controllers and I/O to standard Ethernet networks for I/O, HMI, and peer messaging.

- 10/100 Mbps single port – Simple RJ‑45 copper connection that plays well with managed switches.

- Predictable commissioning – Static IP or BootP/DHCP addressing; built‑in status LEDs and web diagnostics on typical builds.

- Producer/consumer data model – Supports implicit I/O connections and RPIs for steady update rates.

- Drop‑in maintenance – In most cases, a straight swap in a 1756 slot with minimal cabinet changes.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756-ENBTA (ControlLogix) |

| Function | EtherNet/IP bridge between 1756 backplane and plant Ethernet |

| Network Interface | 1 × RJ‑45 (10/100Base‑T), managed switch recommended (IGMP Snooping/Querier for multicast) |

| Backplane | ControlLogix 1756 backplane data exchange to controller/I/O modules |

| Addressing / Setup | Static IP or BootP/DHCP; configured in Studio 5000/Logix; web pages on typical variants |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment |

| Power Requirements | Powered via 1756 chassis backplane; no separate external power on the module |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | Single‑slot 1756 module; ~145 × 35 × 140 mm; ~0.3–0.5 kg |

| Installation Method | Insert into 1756 chassis slot; connect RJ‑45 to managed switch; follow grounding/EMC best practices |

Application Fields

This model shows up wherever stable EtherNet/IP connectivity is the aim and a straightforward single‑port bridge is enough:

- Remote EtherNet/IP I/O islands on packaging, material handling, and OEM skids.

- HMI/SCADA links to ControlLogix controllers across segmented control networks.

- Drive communications and MCC panels where 10/100 performance is sufficient.

- Brownfield replacements for legacy bridges with minimal cabinet rework.

A controls tech told me recently, “We set the IP with BootP, mapped the I/O path, and the connections went green in one pass.” That’s been typical when switches are set up with IGMP Snooping and the cabling is tidy.

Advantages & Value

- Reliability – Proven 24/7 duty with clear LEDs and simple troubleshooting.

- Compatibility – Native to ControlLogix; works with standard managed switches and EtherNet/IP devices.

- Cost control – Keeps installed systems productive without a cabinet redesign.

- Maintainability – Familiar Logix workflows and web diagnostics cut outage time.

- Scalability – A common spare you can standardize across multiple panels.

Installation & Maintenance

- Networking: Use managed switches with IGMP Snooping/Querier for multicast; segregate control VLANs to keep jitter low.

- Cabling: Shielded CAT5e/6; keep away from VFD motor leads; maintain bend radius and proper bonding.

- Addressing: Reserve IPs; disable BootP after setting a static address; document in the panel folder.

- Firmware: Align module firmware with controller/project expectations; ControlFLASH/Studio 5000 handles updates cleanly.

- Routine care: Periodic dust removal, chassis mounting check, and a quick review of port counters and error logs.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE/UL/cUL markings apply at the module/system level when installed per Rockwell guidance.

- RoHS status depends on series/lot; we can confirm by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.