Description

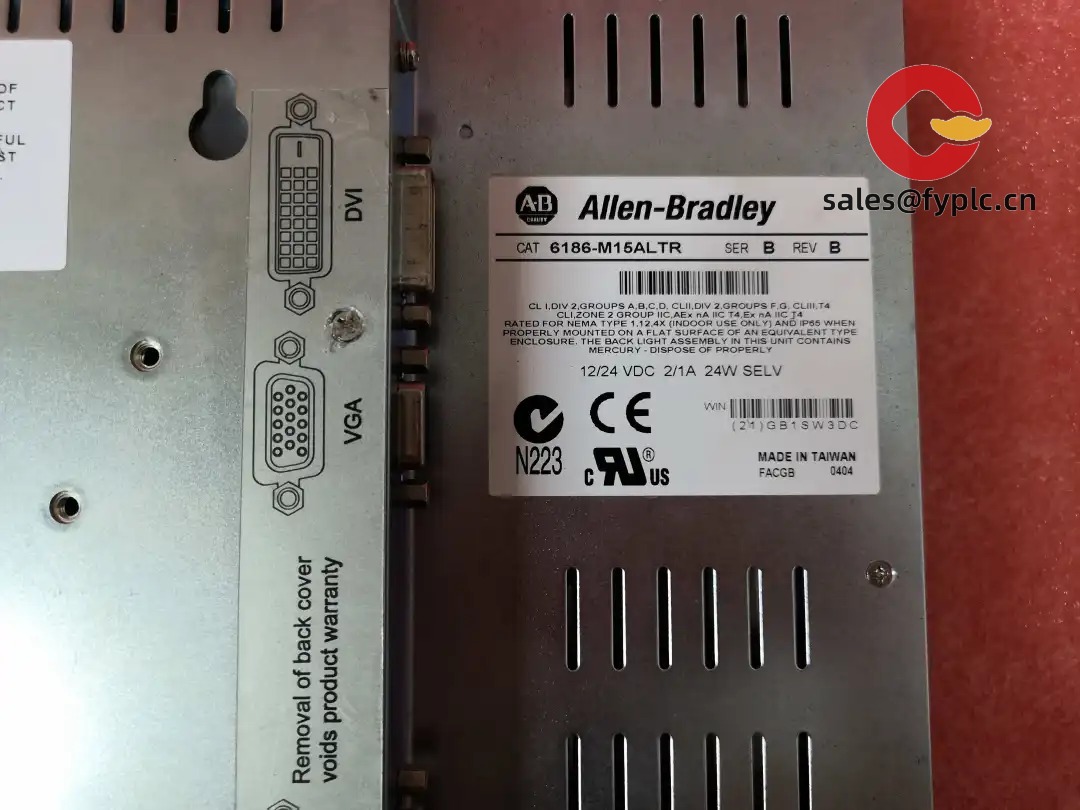

Allen‑Bradley 6186-M15ALTRB Industrial Monitor – 15-inch panel-mount touchscreen for rugged HMI duty

The Allen‑Bradley 6186‑M15ALTRB is part of the 6186 industrial monitor family. Based on the model code, it appears to be a 15‑inch panel‑mount unit with an aluminum front bezel and a resistive touchscreen—exactly the style many plants prefer for glove‑friendly HMI workstations. From my experience, these 6186 monitors are a solid fit when you want a straightforward screen driven by an industrial PC or PLC‑based HMI, with standard video and a simple USB touch interface rather than a proprietary panel.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- 15-inch resistive touchscreen

– Glove‑friendly single‑touch control; typically supplied with USB touch controller for easy PC/HMI integration. - Panel‑mount, aluminum bezel

– Clean, robust front with gasketed seal; well suited to NEMA/IP rated enclosures when properly installed. - Standard video connectivity

– Works with common industrial PCs via VGA/DVI‑D in many cases; keeps spares and cabling simple. - Industrial‑temperature design

– Built for control cabinets and shop‑floor environments where 24/7 duty is the norm. - LED‑backlit LCD

– Stable brightness and lower heat, which typically helps with enclosure thermal management. - Serviceable in minutes

– Front panel access and standard mounting hardware make replacements straightforward during outages.

Technical Specifications

| Brand / Model | Allen‑Bradley 6186‑M15ALTRB (15-inch Industrial Monitor) |

|---|---|

| HS Code | 852852 (Flat panel monitors, of a kind used with ADP systems) |

| Power Requirements | 100–240 VAC, 50/60 Hz (integrated power supply, typical for 6186 series) |

| Operating Temperature | Typically 0 to +50 °C in a non‑condensing cabinet environment |

| Signal Input/Output Types | Video: VGA and/or DVI‑D (typical); Touch: USB (resistive single‑touch) |

| Communication Interfaces | USB for touch controller; standard video connectors for PC/HMI sources |

| Dimensions & Weight | 15-inch panel‑mount form factor; panel cutout per series drawing (request if needed) |

| Installation Method | Front panel mount with gasket and clips; rated front when installed to spec |

Application Fields

This model is typically used as the operator interface in cabinets where a separate industrial PC or PLC‑based HMI drives the screen:

- Packaging and material handling – HMI stations on lines where gloves and frequent cleaning are common.

- Water/Wastewater – SCADA panels with fanless box PCs and simple resistive touch HMIs.

- Power, oil & gas, chemicals – MCC and process skids using industrial PCs for runtime software.

- Machine retrofits – Replace aging CRTs or proprietary panels with standard video monitors.

- Utilities & infrastructure – Local control stations tied to plant networks.

Advantages & Value

- Straightforward integration – Standard video and USB touch keep the setup simple with most industrial PCs.

- Glove‑friendly operation – Resistive touch works reliably where capacitive screens can be finicky.

- Serviceability – Panel‑mount format and familiar hardware mean faster swaps during tight outages.

- Lifecycle practicality – Using a monitor plus PC avoids lock‑in to a single HMI platform.

- Compatibility – Plays nicely with Rockwell software stacks and typical third‑party HMI runtimes.

Installation & Maintenance

- Cabinet & sealing – Follow the panel cutout and torque pattern; fit the gasket evenly to maintain the front rating.

- Ventilation – Provide airflow or heat dissipation for the PC and monitor; avoid hot spots near VFDs.

- Wiring – Use quality shielded video cables; keep video/USB away from power runs; secure strain reliefs.

- Touch setup – Install the USB touch driver where required; run a quick 4‑ or 9‑point calibration.

- Cleaning – Use non‑abrasive cleaners on the bezel/screen; avoid solvents that can haze the touch layer.

- Spare strategy – Keep one spare monitor per line or area; it typically prevents extended downtime after a screen fault.

Quality & Certifications

- Compliance – Typically CE and UL/cUL for industrial monitors in this family; RoHS conformance is common.

- Front rating – NEMA/IP style sealing when correctly panel mounted with the supplied gasket (verify against your enclosure spec).

- Warranty – 365 days from delivery.

A maintenance tech on a packaging line told me, “We swapped in a 6186 monitor during lunch—USB touch synced right up and production didn’t even notice.” That’s usually what teams are after: predictable behavior without a lot of rework.

Reviews

There are no reviews yet.