Description

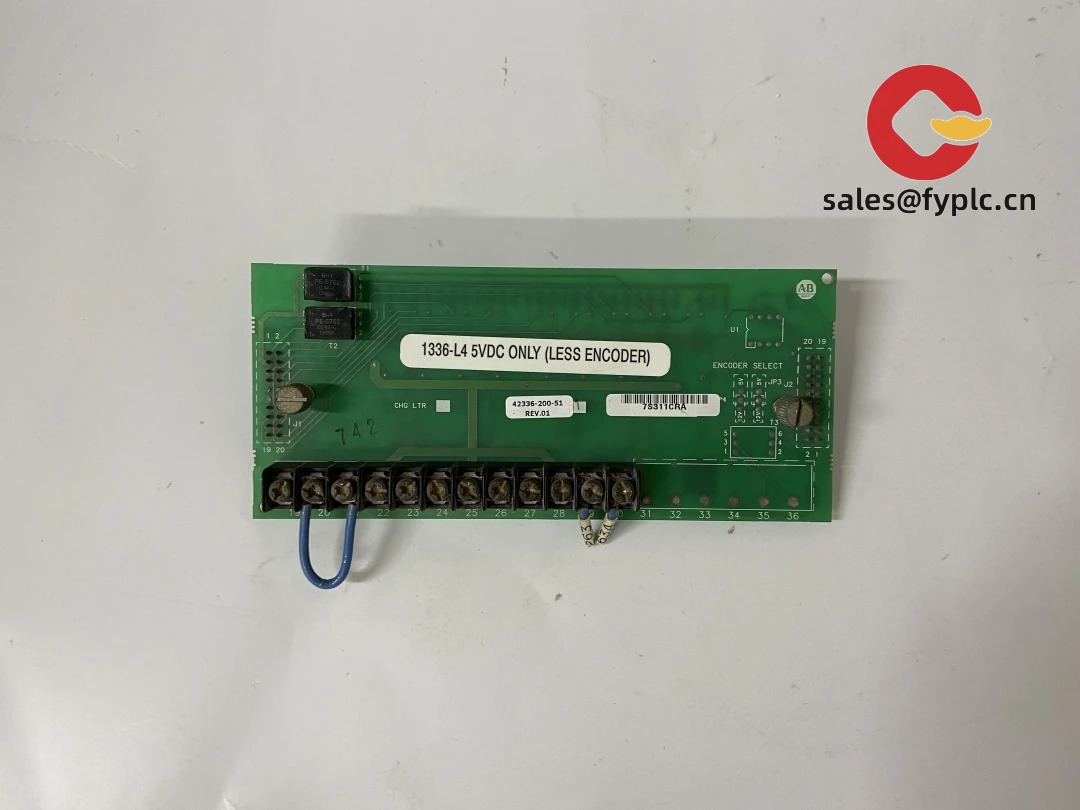

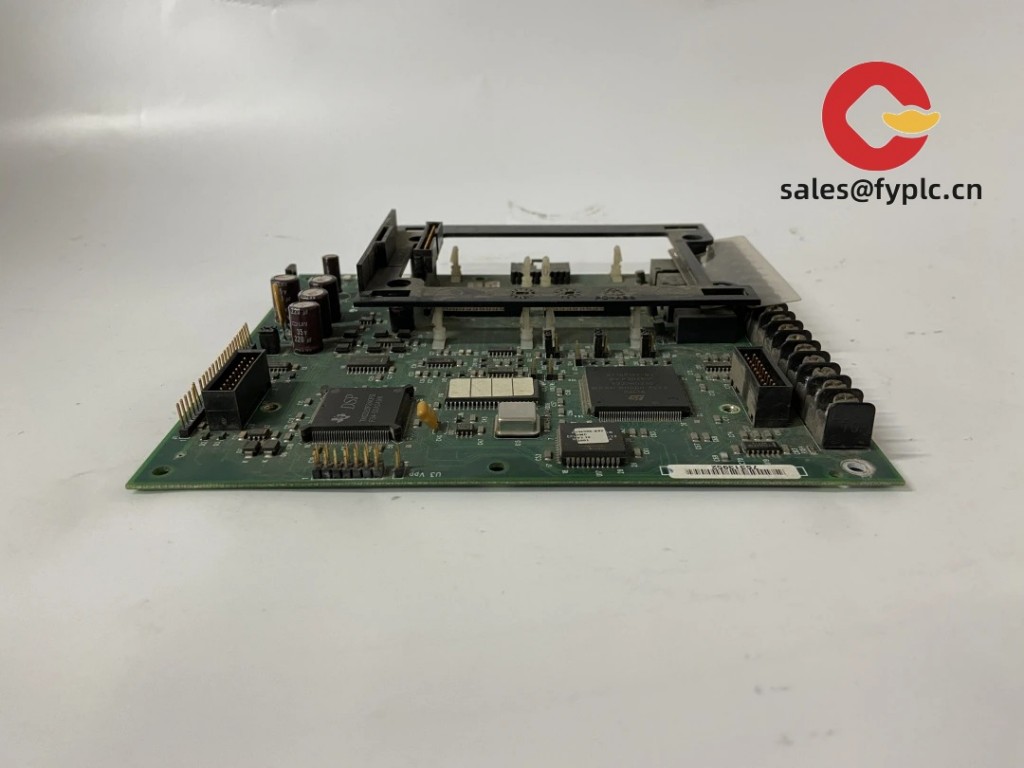

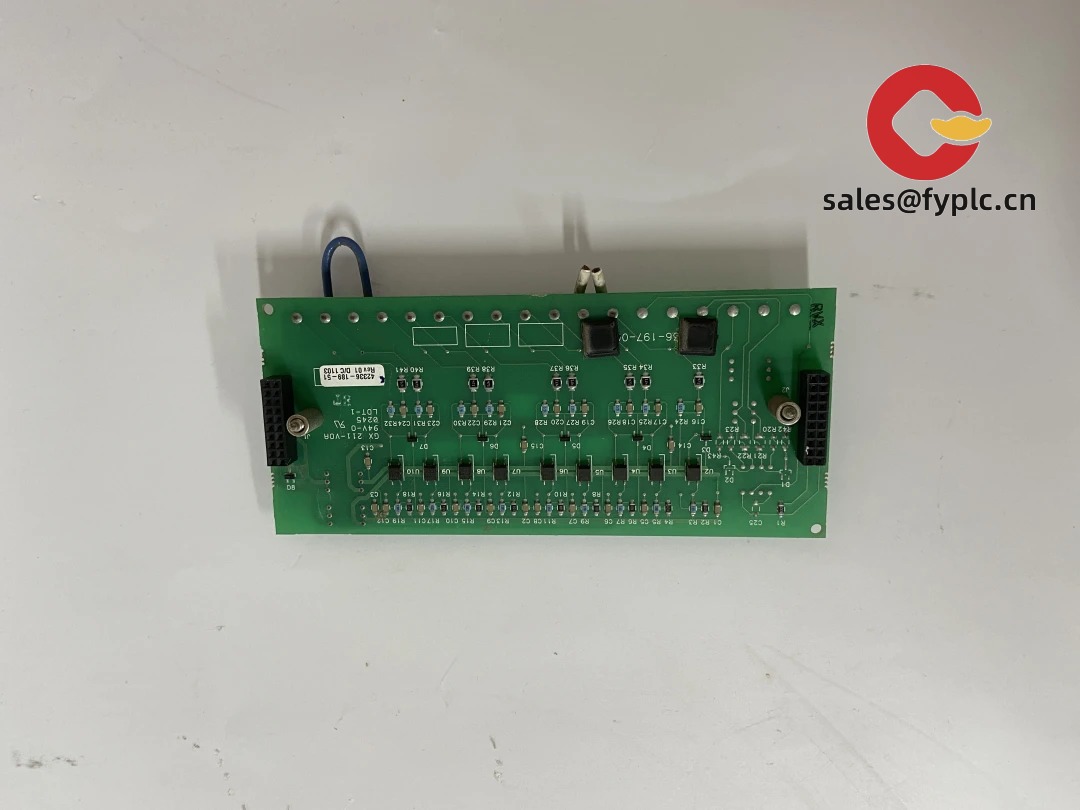

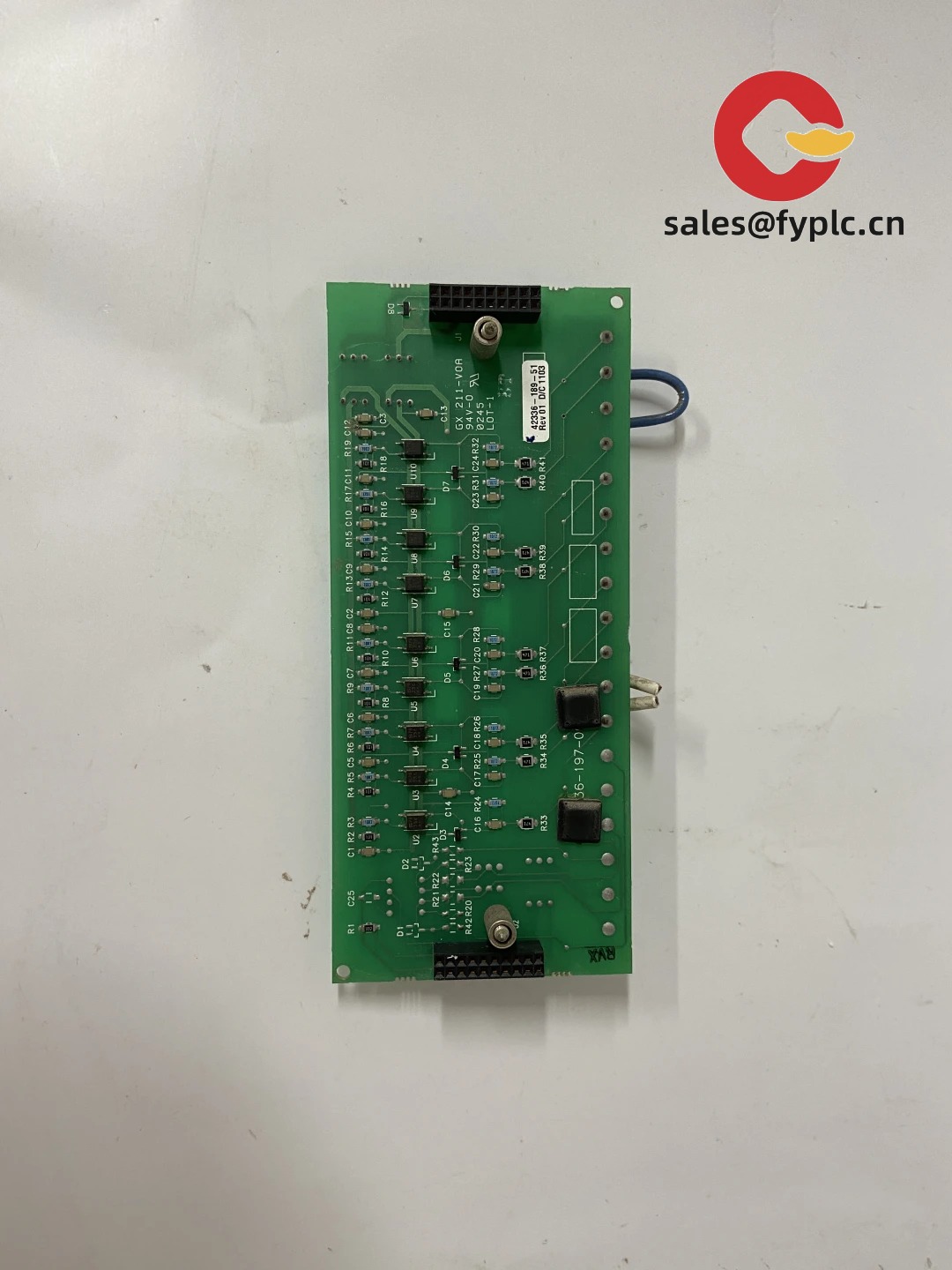

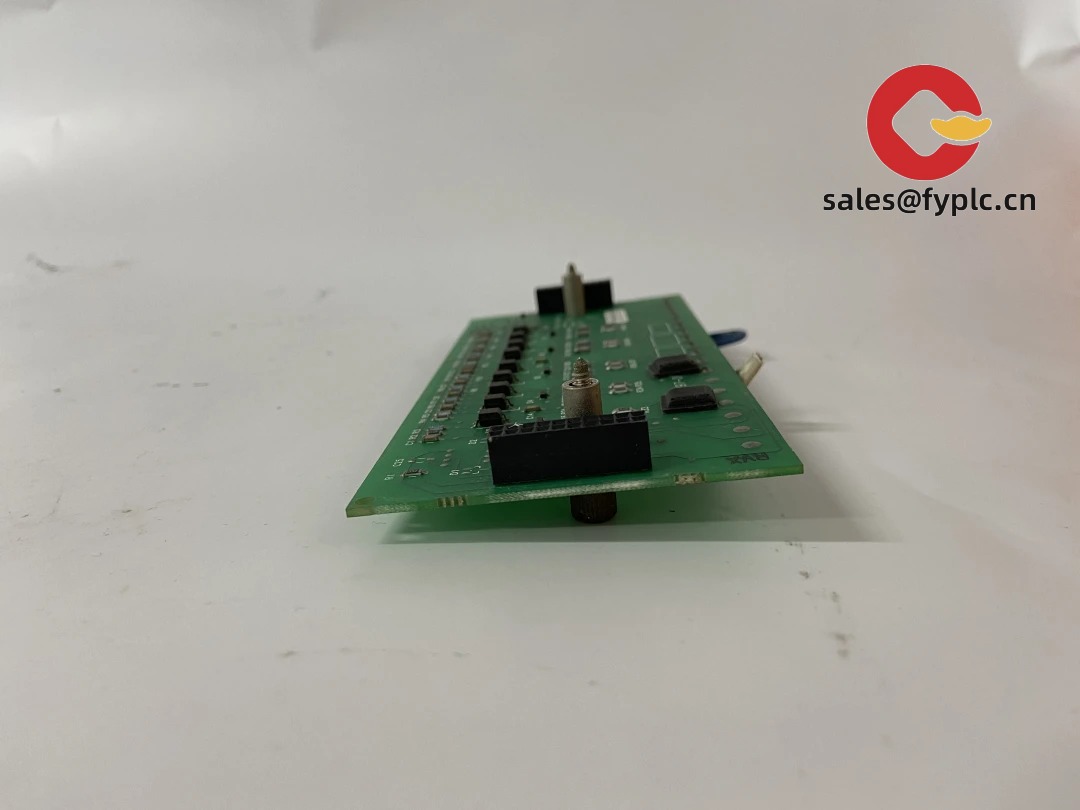

Allen‑Bradley 1336-L4 – Local Operator Interface/Keypad Assembly for 1336 Plus/Force Drives

The Allen‑Bradley 1336-L4 is a local operator interface (LOI) / keypad assembly used on Bulletin 1336 Plus/Force variable‑frequency drives. From my experience, plants keep this part as a straight drop‑in for failed or weathered keypads—especially when the drive still runs but the local display or keys are unreliable. You might notice that the module connects to the drive’s low‑voltage control board with a short ribbon harness; that makes a swap fast during a short outage, with no cabinet rewiring.

Company’s Order Placement Process and Guarantees

- The warranty period is 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification and keypad/display integrity check; ESD‑safe, shock‑resistant packing

Key Features

- Drop‑in keypad/display – Restores local start/stop, speed adjust, status viewing, and parameter editing on 1336 drives.

- Fast swap mechanics – Front‑panel mounting with a keyed ribbon to the control board keeps changeovers predictable.

- Clear status readout – Segment/LCD display (series‑dependent) for drive status, faults, and parameter values.

- Service‑friendly keys – Tactile membrane keys for navigation and entry; labeling matches the 1336 user workflow.

- Built for 24/7 use – Robust faceplate and gasketed bezel (where fitted) to handle cabinet environments.

Technical Specifications

| Brand / Model | Allen‑Bradley 1336-L4 |

| Compatible Family | Bulletin 1336 Plus / 1336 FORCE VFDs (confirm by drive catalog number and series) |

| HS Code (reference) | 8538.90 – Parts for electrical control equipment (final classification may vary by country) |

| Power Requirements | Powered by drive low‑voltage rails via ribbon/board connector (no external supply) |

| Signal I/O Types | Keypad matrix and display interface to the drive control board; no field I/O terminals on the module |

| Communication Interfaces | Internal to the drive; external fieldbus handled by separate option cards |

| Operating Temperature | Typically 0…+50 °C inside the drive enclosure (non‑condensing) |

| Dimensions & Weight (approx.) | Panel module form factor; ~120 × 90 × 35 mm; ~0.15–0.3 kg |

| Installation Method | Front‑panel mount on the 1336 drive; connect keyed ribbon to the control board; secure screws/clips |

Application Fields

A simple, effective fix whenever local drive operation and diagnostics matter:

- Packaging and material handling – quick setpoint tweaks and fault resets at the cabinet.

- Pulp & paper, textiles – on‑machine parameter edits without a laptop.

- Water & wastewater – clear alarm codes for blowers and pump drives in MCCs.

- Metals and converting – fast recovery when the original keypad display fades or keys fail.

A maintenance tech told me last week, “We clipped in the L4 keypad, moved the ribbon, and the 1336 responded right away—no parameter drama.” That’s been typical when the drive series matches and the connector is seated firmly.

Advantages & Value

- Reliability – Restores a solid, tactile interface for 24/7 operation.

- Compatibility – Native fit for 1336 Plus/Force; preserves cabinet layout and wiring.

- Cost control – Board‑level repair avoids full drive replacement and re‑engineering.

- Support – We can help confirm series compatibility and any bezel/ribbon variations before shipment.

- Lead‑time clarity – Practical deliveries aligned with outage planning.

Installation & Maintenance

- Safety & ESD: Lock out the drive; wait for DC bus discharge; handle with a grounded wrist strap.

- Swap steps: Photograph routing; disconnect old ribbon; mount new keypad; seat the keyed connector fully; tighten fixings evenly.

- Checks: Power up and verify display, key response, and local control enable; review fault history for confirmation.

- Care: Keep the faceplate clean and dry; inspect ribbon and clips during PMs; confirm gasket condition if panel‑mounted.

Quality & Certifications

- Built to Rockwell Automation/Allen‑Bradley quality standards (ISO 9001 aligned).

- System compliance (CE/UL) is maintained at the drive level; this is a spare component.

- RoHS status depends on build lot; we can confirm by part/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.