Description

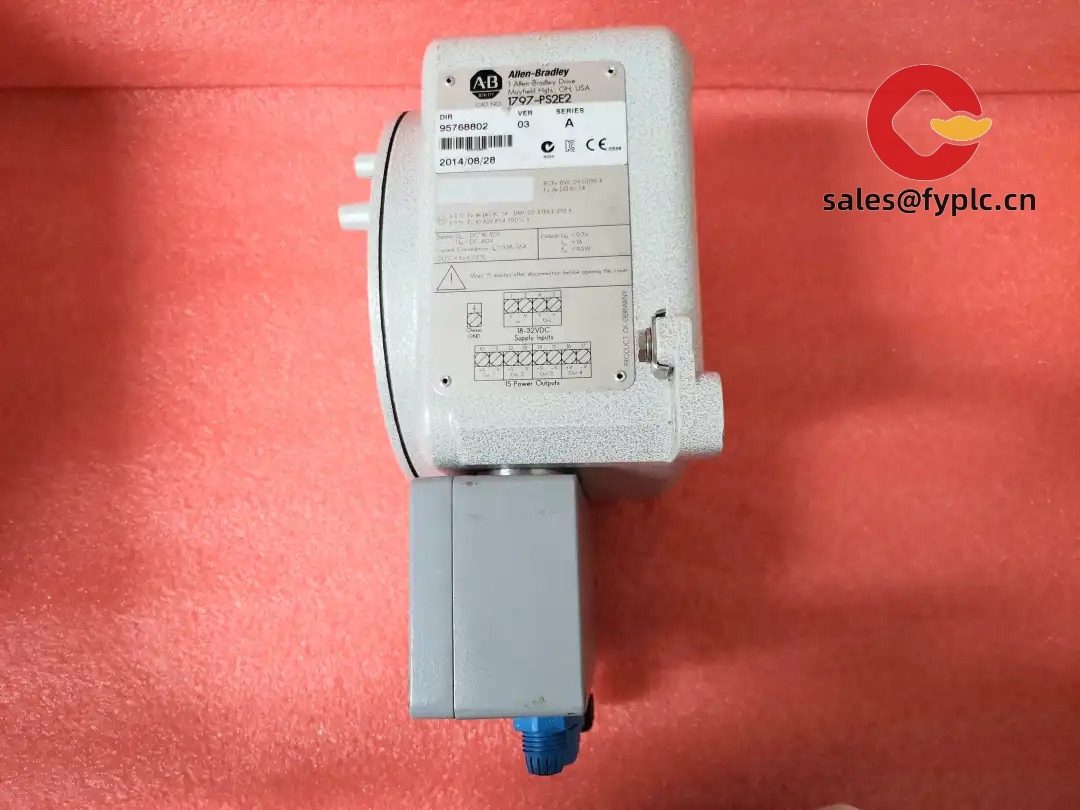

Allen‑Bradley 1797‑PS2E2A – FLEX Ex Power Supply Module for Hazardous‑Area I/O Racks (Series A)

The Allen‑Bradley 1797‑PS2E2A is a FLEX Ex power supply module used to provide stable bus power to 1797 (FLEX Ex) intrinsically safe I/O assemblies. From my experience, plants choose this unit when they want a straightforward, like‑for‑like way to energize FLEX Ex nodes in hazardous‑area projects—typically Zone/Div applications where clean bus power and predictable diagnostics matter. You might notice the robust terminaling and front LEDs; those details tend to make commissioning and swap‑outs fast during tight outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and terminal/LED check; ESD‑safe, shock‑resistant packing

Key Features

- FLEX Ex bus power – Supplies regulated power to 1797 intrinsically safe I/O assemblies for hazardous‑area projects.

- Diagnostics at a glance – Front status LEDs (input/bus) help you confirm power health in seconds.

- 24 V DC plant integration – Typically accepts standard control‑panel DC input and conditions it for the FLEX Ex bus.

- Redundancy‑friendly – In many cases can be paired/configured to support higher availability architectures.

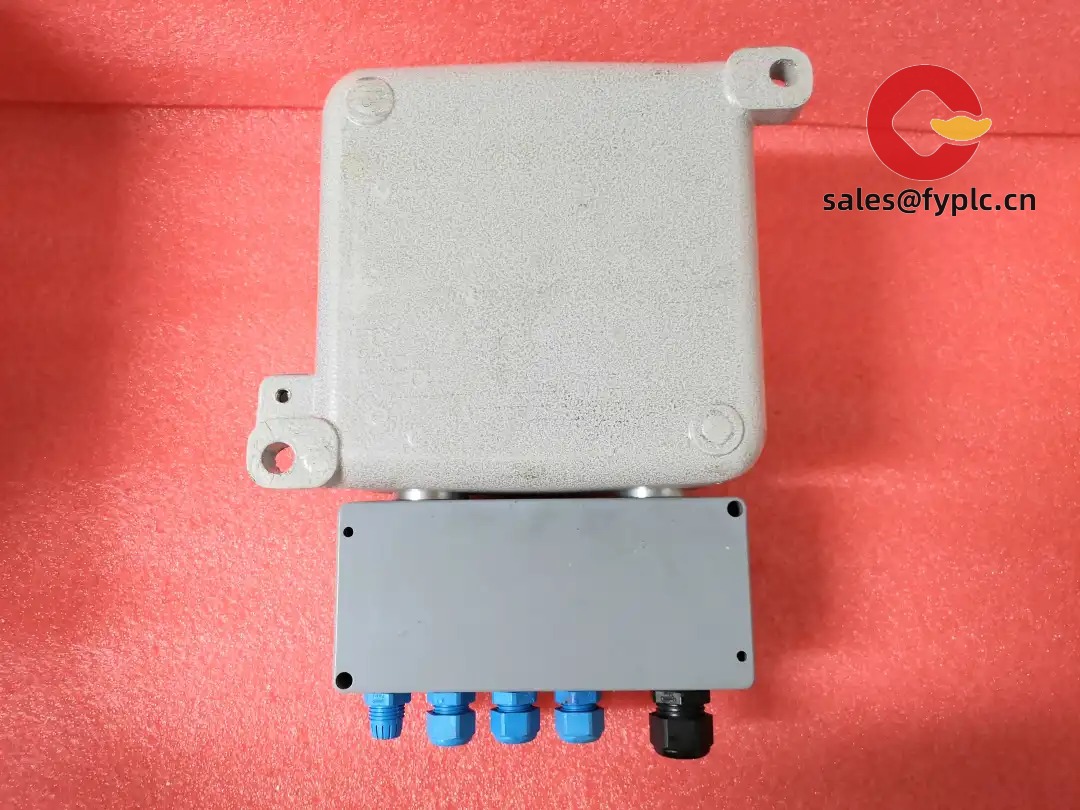

- Service‑friendly mechanics – DIN‑rail mounting and clear terminaling make swap‑outs predictable during short outages.

Technical Specifications

| Brand / Model | Allen‑Bradley 1797‑PS2E2A (Series A) |

| System Family | FLEX Ex (1797) – intrinsically safe I/O platform power supply |

| HS Code (reference) | 8504.40 – Static converters / power supplies (final classification may vary by country) |

| Power Requirements (input) | 24 V DC nominal (typical control‑panel supply; consult nameplate for range) |

| Outputs | FLEX Ex bus power for 1797 I/O assemblies; front LED status indication |

| Communication Interfaces | None (power module; no network ports) |

| Operating Temperature | Typically 0…+55 °C (enclosure‑installed; non‑condensing) |

| Installation Method | DIN‑rail in a grounded enclosure; wire DC input and FLEX Ex bus per hazardous‑area design |

Application Fields

You’ll typically see the 1797‑PS2E2A wherever intrinsically safe I/O is deployed with FLEX Ex:

- Oil & gas and petrochem – Zone/Div rated process areas with IS instrumentation.

- Chemicals & refining – hazardous skids where clean IS bus power is essential.

- Utilities & power – boiler or fuel‑handling areas with IS field devices.

- Pharma and F&B – solvent rooms or classified spaces using FLEX Ex I/O.

One thing I appreciate is how predictable the diagnostics are. A field tech told me, “We landed 24 V DC, watched the bus LED go healthy, and the Ex node came online right away.” That mirrors what I usually see when the wiring and classification paperwork are tidy.

Advantages & Value

- Reliability – Stable bus power designed for continuous duty around IS I/O.

- Compatibility – Native to FLEX Ex; keeps cabinet layout and drawings consistent.

- Maintainability – Clear LED status and straightforward terminals shorten outage windows.

- Cost control – Like‑for‑like replacement that avoids re‑engineering hazardous‑area I/O.

- Support – We can help review input rating, IS loop considerations, and basic power budgeting before your window.

Installation & Maintenance

- Panel practices: DIN‑rail mount in a clean, ventilated enclosure; bond to ground; keep ambient typically 0…55 °C.

- Wiring: Use a stable 24 V DC source; route IS bus wiring per hazardous‑area design; maintain shield and earth continuity.

- Classification: Install and operate according to the certified area ratings and the site dossier (Zone/Div documentation).

- Redundancy (if used): Follow the FLEX Ex guide for pairing and load sharing; verify both modules’ LED status.

- Routine care: Periodic dust cleaning, terminal re‑torque, and quick LED checks during PMs; log input voltage and bus health.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- Hazardous‑area approvals are variant/installation dependent; we can verify by part/serial.

- CE/UL/cUL applicability per system configuration; RoHS status confirmable by lot.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.