Description

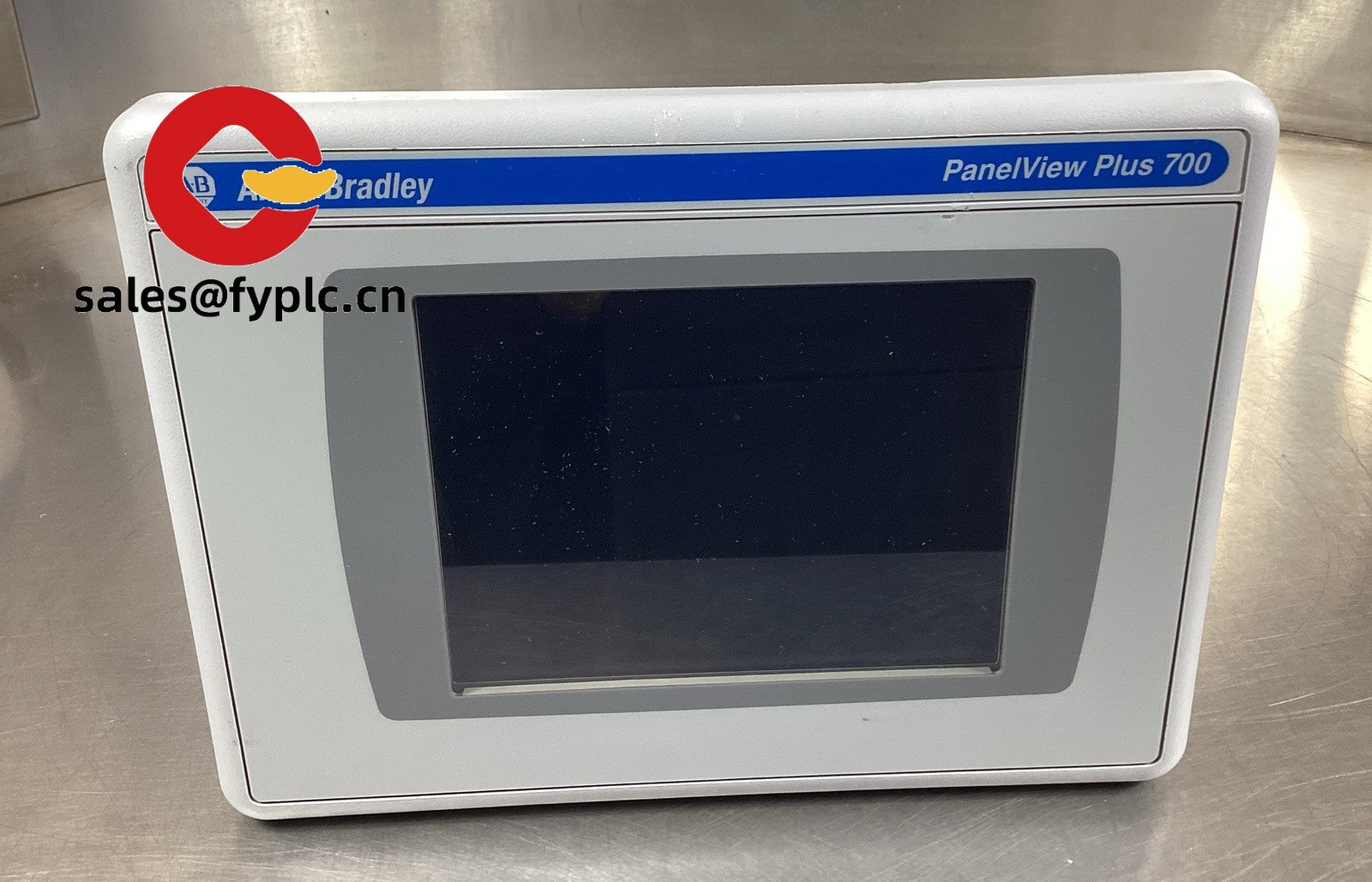

Allen‑Bradley 2711P-RDT7C – Replacement Color Touch Display Module for PanelView Plus 700

The Allen‑Bradley 2711P-RDT7C is the factory replacement display module for PanelView Plus 700 terminals. It’s the piece you swap in when a screen is cracked, dim, or the touch layer has worn out—without touching your logic module, application, or wiring. From my experience, this is the quickest way to recover an HMI that’s gone dark and avoid hours of revalidation.

You might notice that the “RDT7C” code says a lot: R for replacement module, D for display, T for touchscreen, and C for color. It’s a 6.5-inch (PanelView Plus 700 class) color TFT with a resistive touch overlay, designed to bolt in with the standard gasket and clips. In most cases it’s drop-in compatible with both PanelView Plus 700 and PanelView Plus 6 700 assemblies, which keeps spare parts planning simple.

Our Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Direct replacement for PV+ 700 front end: Keeps the existing logic module, firmware, and program intact to minimize downtime.

- Color TFT with resistive touch: Clear visualization and a proven, glove‑friendly touch layer that’s easy to calibrate.

- Front panel environmental rating: Typically NEMA 4X/12 and IP65 on the bezel when installed with the proper gasket and clips.

- Replaceable backlight: Backlight service life is typically long enough for multi‑year duty; field replacement is straightforward.

- Panel‑mount form factor: Same cutout as standard PanelView Plus 700, so no rework of the enclosure door.

- Modular service strategy: Swap just the failed display/touch section instead of replacing a complete terminal.

Technical Specifications

| Brand / Model | Allen‑Bradley 2711P-RDT7C |

| HS Code | 8537.10 (Operator interface for electric control) |

| Product Type | Replacement color display + resistive touchscreen module for PanelView Plus 700 |

| Power Requirements | Supplied by the attached PanelView Plus logic module (nominal 24 VDC system) |

| Display Size & Resolution | Approx. 6.5 in TFT color; typically 640 × 480 (VGA) |

| Touchscreen | Analog resistive, single‑touch; calibration via terminal settings |

| Operating Temperature | 0 to 55 °C (typical for PanelView Plus family) |

| Front Panel Rating | NEMA 4X/12, IP65 when properly installed on a flat, sealed panel |

| Signal I/O Types | Touch input only (no field I/O on display module) |

| Communication Interfaces | Provided by the logic module (e.g., Ethernet, RS‑232, USB vary by 2711P‑RPxx) |

| Installation Method | Panel‑mount with gasket and mounting clips; mates to 2711P logic module |

| Dimensions & Weight | Fits the standard PanelView Plus 700 cutout; weight varies by assembly |

| Compatibility | PanelView Plus 700 and, in many cases, PanelView Plus 6 700 terminals |

Application Fields

This module is used anywhere a PanelView Plus 700 front end needs service or an HMI screen upgrade. Typical examples:

- Packaging and converting lines where touch response has degraded from heavy glove use

- Water/wastewater panels with faded backlights after long runtime

- Material handling and intralogistics HMIs needing quick, like‑for‑like swaps

- Food & beverage lines that require NEMA 4X/12 front sealing in washdown areas (indoor)

- OEM machine upgrades keeping the logic module and program unchanged

“We replaced three 2711P-RDT7C screens during a planned stop—each took under 20 minutes and the operators were back running with no recipe reloading.” — Maintenance Supervisor, discrete manufacturing

Advantages & Value

- Reduced downtime: Swap the front module and keep your logic module and application as‑is.

- Lower total cost: Replace only what failed instead of a full HMI terminal.

- Compatibility headroom: Works with common 2711P‑RPxx logic modules, so your spares strategy stays consistent.

- Serviceable design: Field‑replaceable backlight and easy touch calibration.

- Proven ecosystem: Backed by widely used Rockwell Automation hardware and software toolchains.

Installation & Maintenance

- Mounting: Panel‑mount on a flat enclosure door using the supplied gasket and clips; tighten evenly for a uniform seal.

- Environment: Provide ventilation to keep the assembly within 0…55 °C; avoid direct spray and corrosives on the bezel.

- Wiring: All I/O/communications stay on the logic module; mate the display module to the logic module carefully to avoid bent connectors.

- Safety: Isolate 24 VDC and lock out power before service. Discharge static and handle the touch surface with clean gloves.

- Routine care: Clean the screen with a soft, non‑abrasive cloth; recalibrate touch if pointer drift is noticed.

- Backlight service: Replace the backlight when brightness falls (life is typically long; kit availability is standard for PV+ 700).

- Firmware: Firmware resides in the logic module; no display‑module updates are required.

Related / Supporting Components

- 2711P‑RP1 / 2711P‑RP2 logic modules: Common PanelView Plus 700 logic cores providing power and communications.

- 2711P‑RL7C backlight kit: Replacement backlight for the color display when brightness degrades.

- Panel gasket and clip sets: Ensure NEMA/IP sealing is maintained after front‑end service.

Quality & Certifications

- Certifications: CE, cULus Listed (industrial control equipment), RoHS compliant

- Manufacturing quality: Produced under ISO 9001 quality systems (typical for Rockwell facilities)

- Manufacturer warranty: As per Rockwell Automation policy; our after‑sales coverage is 365 days

One thing I appreciate is how consistent the mechanical design is across the PV+ 700 family—if your panel already accepts a standard PV+ 700, this module usually drops straight in, saving you from re‑cutting doors or chasing new gaskets.

Reviews

There are no reviews yet.