Description

Allen‑Bradley 1746-A7 – 7‑Slot SLC 500 Chassis for Modular PLC Systems

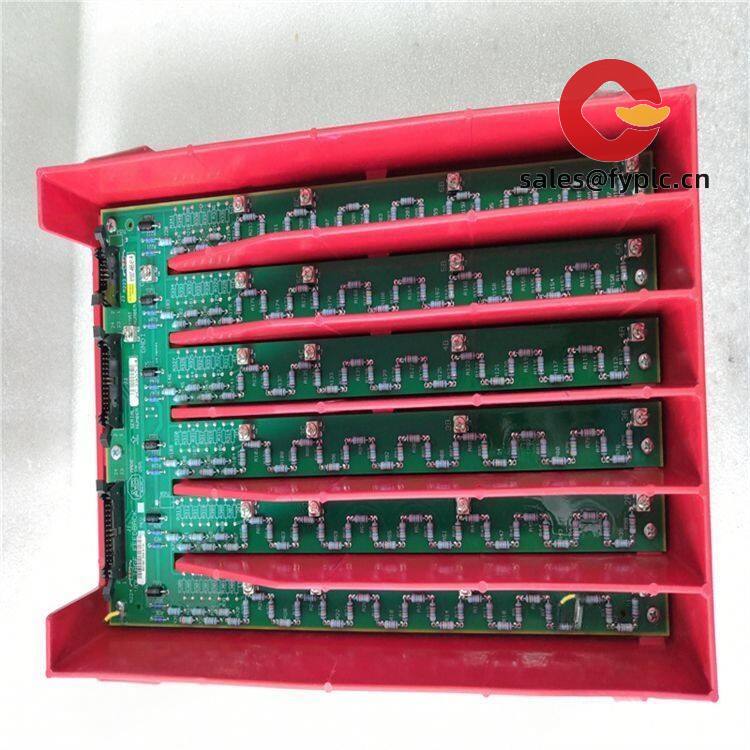

The Allen‑Bradley 1746-A7 is the 7‑slot chassis in the SLC 500 family, built for compact, modular control systems where you need the right balance of capacity and panel space. It houses your SLC processor, 1746 I/O modules, and the left‑side 1746-Px power supply on a robust backplane. From my experience, the A7 hits a sweet spot for most OEM machines and mid-size process skids—enough slots for CPU, comms, and mixed I/O without forcing a larger enclosure.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: Typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

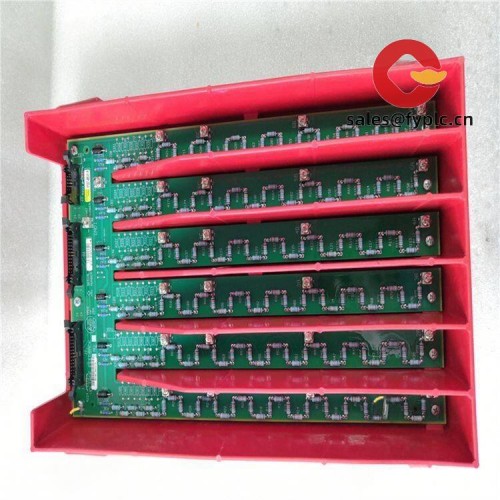

- 7‑slot modular backplane – Room for an SLC 5/0x CPU plus a practical mix of digital, analog, and specialty I/O.

- Power on the left – Accepts 1746-Px power supplies; quick swap without disturbing the I/O stack.

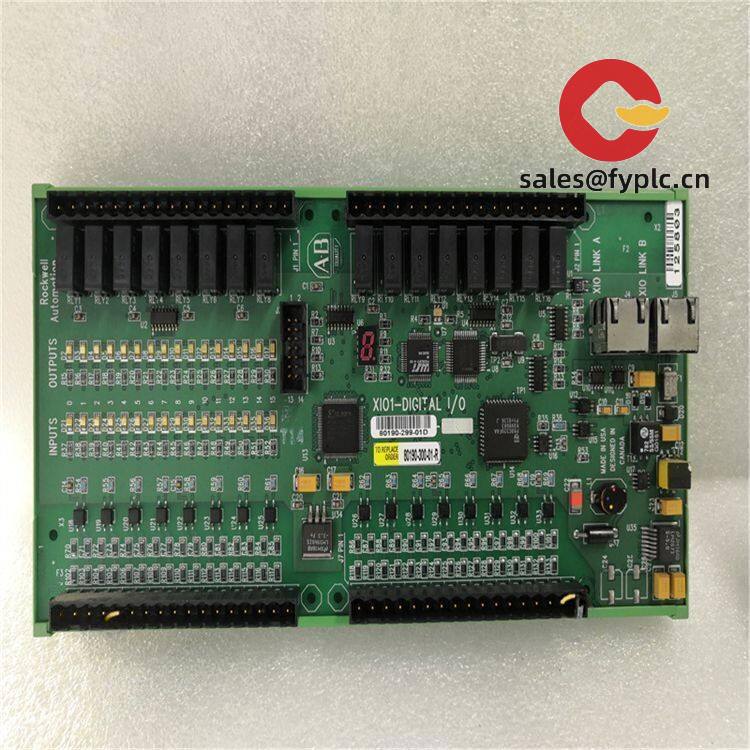

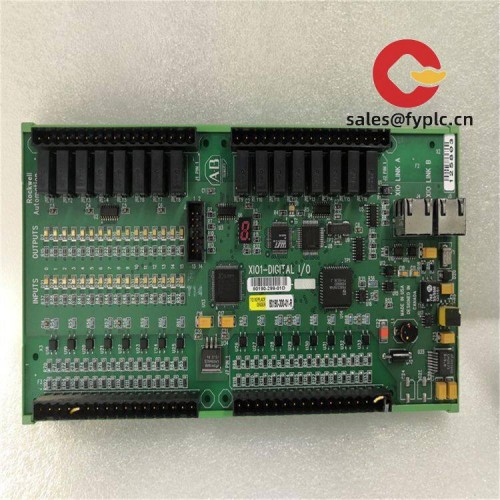

- Full 1746 I/O compatibility – Supports standard 1746 digital (AC/DC), analog, high‑speed, and specialty modules.

- Processor flexibility – Works with SLC 5/01…5/05 controllers, including Ethernet-enabled SLC 5/05 for plant‑wide integration.

- Rugged, panel‑mount design – Mechanical stability for continuous industrial service.

- Serviceability – Front access for module latching and wiring; you might notice how fast module changeouts go during downtime.

Technical Specifications

| Brand / Model | Allen‑Bradley 1746-A7 (SLC 500 series) |

| HS Code | 8538.90 (Parts suitable for apparatus of heading 8537) |

| Power Requirements | Powered via left‑mounted 1746-Px power supply (AC: 1746-P1/P2; DC: 1746-P3, etc.); no direct chassis input |

| Slot Count | 7 module slots (supports CPU, comms, and I/O) |

| Dimensions & Weight | Typical H 140 mm (5.5 in) × W ~370–375 mm (~14.6–14.8 in) × D ~140–150 mm (~5.5–5.9 in); approx. 1.8–2.2 kg |

| Operating Temperature | 0 to 60 °C (32 to 140 °F); 5–95% RH, non‑condensing |

| Signal Input/Output Types | Backplane only; accepts 1746 I/O modules (digital AC/DC, analog, counter/pulse, specialty) |

| Communication Interfaces | None on chassis; comms via installed CPU/modules (e.g., RS‑232/485, DH+, Ethernet on SLC 5/05 or add‑ons) |

| Installation Method | Panel mounting (horizontal), secure at four points; allow ventilation clearance |

| Supported Controllers | SLC 5/01 through SLC 5/05 (1747‑L5x series) |

Application Fields

The 1746-A7 is typically chosen for machines and lines that need a solid, serviceable PLC platform without a big rack footprint:

- Discrete manufacturing and packaging skids (labelers, fillers, cartoners)

- Material handling and conveyor zones (merge/divert, accumulation)

- Water/Wastewater compact panels (pumps, blowers, chemical dosing)

- HVAC and utilities controls inside process plants

- OEM equipment upgrades where SLC compatibility is a must

A maintenance lead told me, “The 7‑slot makes our life easier—CPU, two comms cards, and a mix of I/O with a spare slot. We’ve kept spares on the shelf and swaps are quick.”

Advantages & Value

- Reliability – Proven SLC 500 hardware that, in many cases, runs for years with minimal intervention.

- Compatibility – Drop‑in fit with existing 1746 I/O and SLC processors; protects your installed base investment.

- Cost control – 7 slots keeps the panel compact and avoids oversizing power supplies or enclosures.

- Service support – Widely supported by technicians; documentation and spares are easy to source.

Installation & Maintenance

- Panel mounting – Mount horizontally on a rigid backplate; keep adequate side/top clearance for airflow and wiring.

- Power supply selection – Choose 1746-Px based on total module load (5V and 24V loads add up fast with analog/specialty modules).

- Grounding and wiring – Bond the panel ground properly; route low‑level analog separately from high‑voltage and inductive loads.

- Environment – 0…60°C ambient; avoid dust and corrosives; add enclosure ventilation or filtering if needed.

- Routine care – Periodically re‑seat modules, inspect the backplane connector fingers, and clean with dry air. Firmware updates apply to the CPU/comms modules, not the chassis itself.

- Expansion – If you foresee expansion, leave a slot free or plan a local expansion chassis; verify cable/module requirements for your SLC CPU.

Quality & Certifications

- CE and UL/cUL listed (SLC 500 family)

- Manufactured under ISO 9001 quality systems

- RoHS status can vary by production date; we typically verify on a per‑lot basis if required

- Manufacturer warranty policies apply; our coverage: 365‑day warranty from delivery

Recommended Supporting Components

- 1746-P1 / 1746-P2 – AC power supplies; pick based on total 5V/24V backplane load and slot count.

- 1746-P3 – 24 VDC power supply option for DC-only panels.

- 1747-L5x – SLC 5/01…5/05 processors (select SLC 5/05 for Ethernet connectivity when needed).

- 1746 I/O modules – Digital (AC/DC), analog (current/voltage), specialty (HSC, temperature, motion interface).

Reviews

There are no reviews yet.