Description

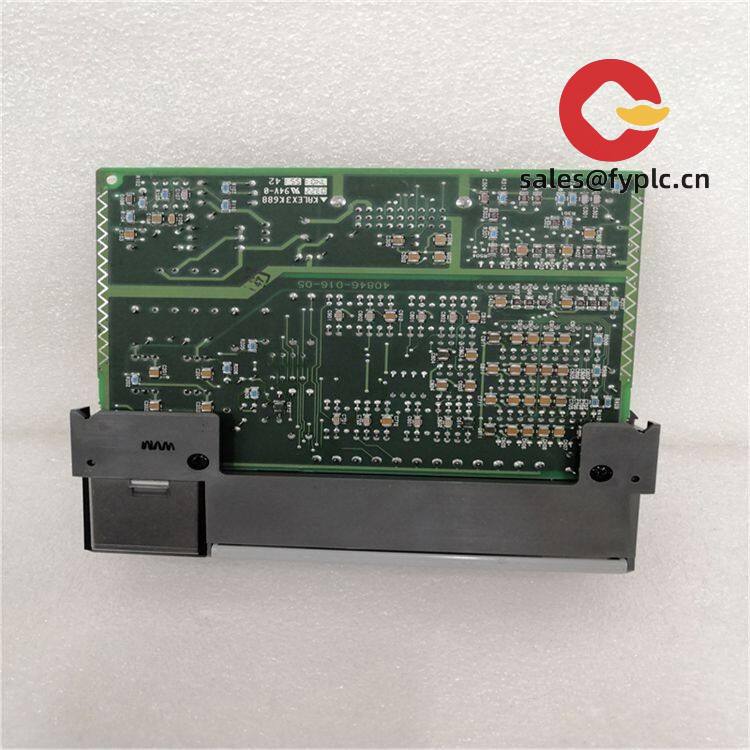

Allen-Bradley 1746-IV16 – 16-Point 24 VDC Sourcing Input Module for SLC 500 Systems

The Allen‑Bradley 1746-IV16 is a 16-channel, 24 VDC sourcing input module designed for the SLC 500 platform. From my experience, it’s a straightforward drop‑in choice when you need reliable digital inputs and clean diagnostics in compact machinery or legacy line expansions. It accepts sinking (NPN) field devices and typically drops into any 1746 chassis without extra power wiring, which keeps panel work simple and tidy.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- 16 DC inputs (24 VDC nominal): Two groups of 8 channels with separate commons for flexible field wiring.

- Sourcing input type: Works with sinking (NPN) sensors and contacts; ideal in systems standardized on NPN field devices.

- Status diagnostics: Individual channel LEDs help technicians spot wiring or sensor issues quickly.

- Backplane powered: No external module power required; power is provided by the 1746 chassis backplane.

- SLC 500 ecosystem: Seamless with 1746 chassis, SLC 5/01–5/05 CPUs, and common power supplies (e.g., 1746-P1/P2).

- Noise‑tolerant filtering: Typical input filtering reduces bounce and electrical noise in real plant environments.

Technical Specifications

| Brand / Model | Allen‑Bradley 1746-IV16 |

| HS Code | 853890 (Parts for apparatus of heading 8537) |

| Power Requirements | Supplied via 1746 SLC backplane (no external module power) |

| Input Voltage Category | 24 VDC nominal (typically 10–30 VDC operating range) |

| Channels / Grouping | 16 inputs; 2 groups of 8 with separate commons |

| Signal Input Type | Sourcing inputs (for sinking/NPN sensors and contacts) |

| Input Response | Debounced; on/off delay typically around 8 ms per channel |

| Communication Interface | 1746 backplane to SLC 500 CPUs (e.g., 5/03, 5/04, 5/05) |

| Installation Method | Single‑slot 1746 chassis module; screw‑terminal field wiring |

| Operating Temperature | 0 to 60°C (32 to 140°F), typical for SLC 500 I/O |

Application Fields

You might notice that the 1746-IV16 shows up in a lot of brownfield upgrades and OEM machines where NPN sensors are the norm. Common uses include:

- Packaging and material handling lines (photoeyes, part present, jam detect)

- Automotive fixtures and assembly stations with NPN proximity sensors

- Water/wastewater skids monitoring float switches and dry contacts

- Food & beverage conveyors with distributed 24 VDC sensing

- General machine control for OEMs standardizing on SLC 500

Advantages & Value

- Dependable in legacy fleets: In many cases it’s a plug‑and‑run replacement, minimizing downtime on established SLC lines.

- Compatibility: Matches sinking/NPN sensors many plants already stock, simplifying spares and standards.

- Serviceability: Channel LEDs and grouped commons make troubleshooting quicker during shifts.

- Cost control: Extends the life of SLC 500 assets without a full platform migration.

- Ecosystem support: Works cleanly with common chassis like 1746-A4/A7/A10 and power supplies such as 1746-P2.

Installation & Maintenance

- Panel/cabinet: Install in a properly grounded 1746 chassis with adequate ventilation; avoid high‑noise power cabling in the same ducting.

- Wiring: Use the two input commons to separate noisy and clean signals where possible; follow sensor polarity (NPN to sourcing input).

- Protection: Add appropriate field fusing and suppression on inductive devices; keep input voltage within the 24 VDC category (typically 10–30 VDC).

- Commissioning: Verify each channel LED and input state in the controller; a quick jog test usually catches mis‑wires fast.

- Routine checks: Re‑torque terminals periodically, clean dust from vents, and inspect for loose conductors or nicked insulation.

- Spare strategy: Many maintenance teams keep at least one spare per line because swap time is just a few minutes.

Quality & Certifications

- Certifications: CE, UL/cUL, CSA (typical for this series)

- RoHS: Current production variants are generally RoHS compliant; legacy stock may vary by date code.

- Manufacturer: Allen‑Bradley / Rockwell Automation

- Warranty: 365 days (provided by us)

One thing I appreciate is how forgiving the 1746-IV16 is during retrofits—status LEDs save time when a sensor is reversed or a common is mixed, which seems to be the typical hiccup during late‑night startups. If your sensors are PNP instead, a complementary option would be the 1746-IB16 (sinking input type) to keep wiring conventions consistent.

Reviews

There are no reviews yet.