Description

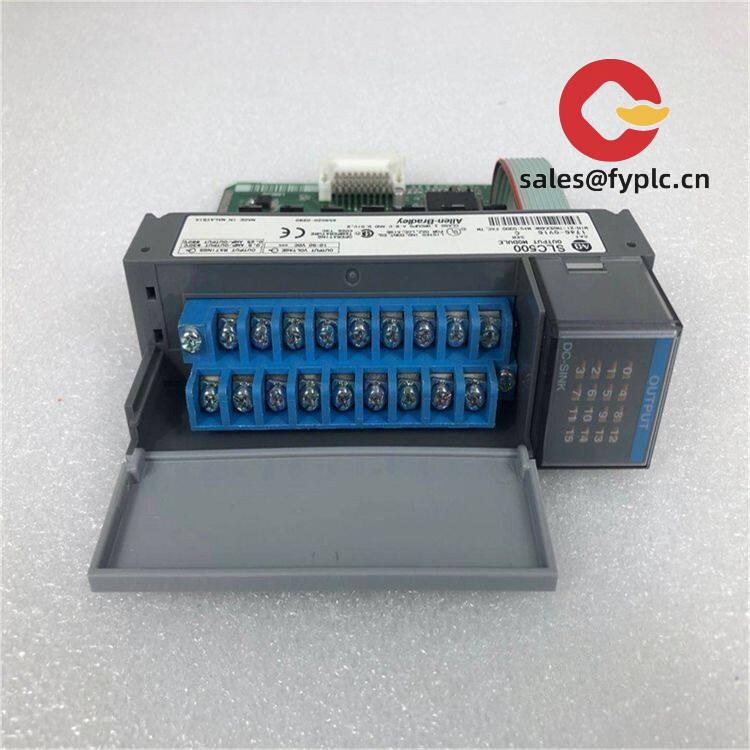

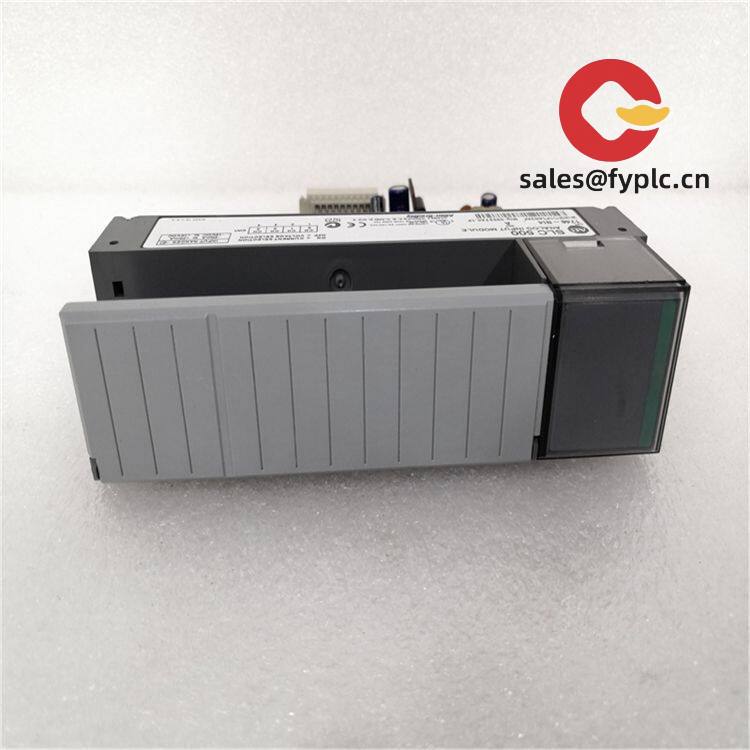

Allen‑Bradley 1746-NI4 – 4‑Channel Analog Input Module for SLC 500 Chassis

The Allen‑Bradley 1746-NI4 is a compact, dependable 4‑channel analog input module designed for the 1746 SLC 500 platform. From my experience, it’s a straightforward way to bring common process signals—like 4–20 mA loop transmitters or 0–10 V sensors—into an SLC 5/03, 5/04, or 5/05 system without fuss. One thing I appreciate is how quickly it drops into an existing 1746 chassis and starts reading stable values, especially in plants that still rely on proven SLC hardware.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- 4 analog input channels – Ideal for compact process skids and small machine upgrades.

- Current or voltage ranges – Typically supports 0–10 V, ±10 V, 0–20 mA, and 4–20 mA; easy to match common transmitters.

- Per‑channel configuration – In many cases you can mix ranges channel‑by‑channel to match field devices.

- Backplane‑powered – No separate supply required; it draws power from the 1746 chassis.

- Removable terminal block (RTB) – Speeds up maintenance and module swaps.

- Signal filtering – Input filtering helps smooth noisy readings coming from long cable runs.

- Status indication – Front LEDs make it easier to check module health at a glance.

Technical Specifications

| Brand / Model | Allen‑Bradley 1746-NI4 (SLC 500 analog input) |

| HS Code | 8537.10 (Programmable control equipment) |

| Power Requirements | Powered via 1746 SLC backplane (no external power supply required) |

| Signal Input Types | 4 analog inputs; typical ranges include 0–10 V, ±10 V, 0–20 mA, 4–20 mA |

| Communication Interfaces | Local SLC backplane only (no external comm ports on module) |

| Operating Temperature | Typically 0 to 60 °C (32 to 140 °F), 5–95% RH non‑condensing |

| Dimensions & Weight | Standard SLC 500 I/O module form factor; fits all 1746 chassis sizes |

| Installation Method | Slot‑mount into 1746 chassis; wiring via removable screw‑type terminal block |

Application Fields

You might notice this module most often in brownfield upgrades or expansions where SLC 500 is still the backbone. Typical uses include:

- Process skids measuring pressure, level, or flow via 4–20 mA transmitters

- Temperature monitoring using transmitter‑converted RTD/TC signals (4–20 mA)

- Packaging machines reading ±10 V feedback from servo/drive analog outputs

- Water/wastewater panels collecting analog signals from field instruments over long cable runs

- Utilities and facility monitoring (pressure, differential pressure, tank level)

Advantages & Value

- Reliability – Proven hardware for plants that prefer stable, long‑lifecycle components.

- Compatibility – Works seamlessly with 1746 chassis and SLC 5/03–5/05 processors; no new software learning curve.

- Cost control – Extends the useful life of SLC systems without a full platform migration.

- Serviceability – RTB wiring and front LEDs reduce downtime during maintenance.

- Support – From my experience, documentation and spare parts availability are still good in most regions.

Feedback from a packaging OEM: “Swapping a failed NI4 took under 10 minutes. Wiring stayed on the RTB, and signal scaling matched right up.”

Installation & Maintenance

- Cabinet & environment – Mount in a 1746 chassis inside a ventilated cabinet. Keep within the specified temperature and humidity range.

- Wiring practices – Use shielded twisted‑pair for analog runs; ground at one end only to minimize noise. Separate analog and high‑voltage wiring.

- Power & loop devices – For 4–20 mA loops, provide clean, isolated 24 VDC loop power where required by the field transmitter.

- Configuration – Set channel ranges to match each device; verify scaling in the SLC data files before going live.

- Routine care – Periodically check terminal tightness, clean dust from ventilation areas, and review readings for drift. Firmware updates are typically not applicable for this module class.

- Safety – De‑energize the chassis before inserting or removing modules unless your specific chassis supports and is configured for hot‑swap (most SLC setups are not).

Quality & Certifications

- Typically complies with CE and UL; CSA recognition common for North America

- RoHS status may vary by production series; we can check specific date codes upon request

- Manufactured to meet industrial control standards used across process and factory automation

- Warranty: 365 days

Practical Notes & Compatible Hardware

Works in 1746 chassis (e.g., 1746-A4/A7/A10/A13) with SLC 5/03–5/05 processors. For stable analog performance, I typically keep the NI4 away from high‑power output modules in the chassis, or insert a spacer if the cabinet heat load is high.

Reviews

There are no reviews yet.