Description

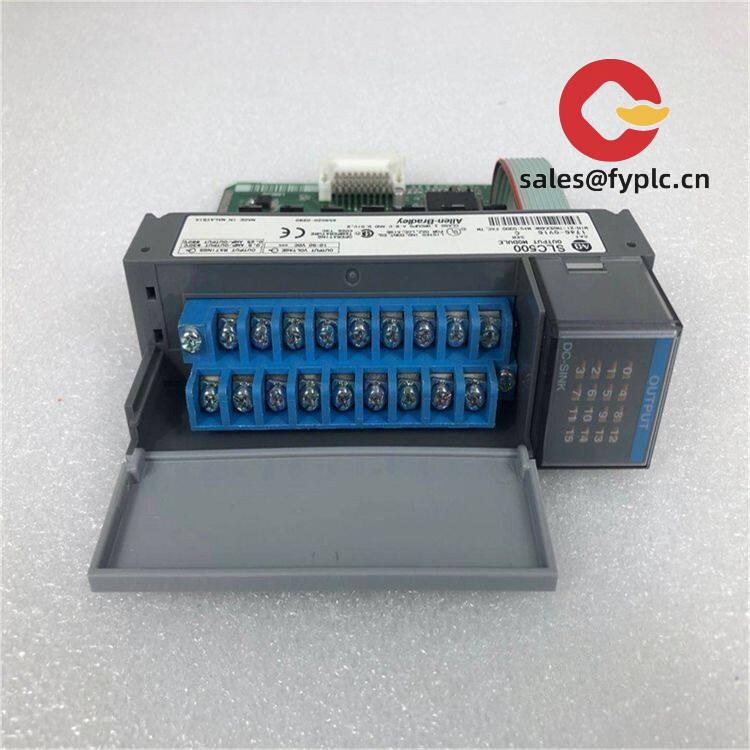

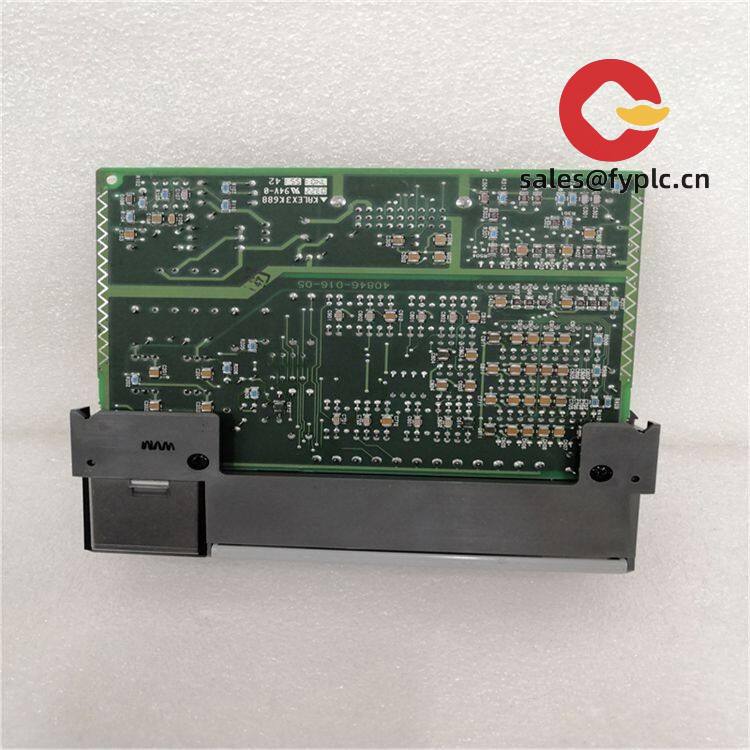

Allen‑Bradley 1746-OV16 – 16‑Point DC Sinking Output Module for SLC 500 Control

The Allen‑Bradley 1746-OV16 is a 16‑channel DC output module designed for the SLC 500 platform. It provides NPN (sinking) transistor outputs for 10–30 VDC loads, which is typically what you want when your field devices are PNP (sourcing). From my experience, it’s a straightforward drop‑in for expanding digital outputs on 1746 chassis without reworking the control architecture. You might notice that it balances easy wiring, clear status indication, and rugged performance that suits most panel environments.

Order Placement Process and Guarantees

- Warranty: 365 days on the supplied unit

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 16 DC sinking outputs (NPN) – Works with sourcing (PNP) field devices in the 10–30 VDC range.

- SLC 500 backplane integration – Plugs into 1746 chassis alongside existing input/output cards; no special adapters.

- Per‑channel status LEDs – Quick diagnostics at the panel; you can confirm output state at a glance.

- External DC supply for loads – Separates field power from backplane power, which typically improves noise immunity.

- Rugged, panel‑friendly design – Suitable for standard control cabinets; seems to be stable in most factory temperature ranges.

- Compatible with existing SLC 500 installs – A practical way to extend or service legacy systems without redesigning I/O maps.

Technical Specifications

| Brand / Model | Allen‑Bradley 1746-OV16 |

| HS Code | 8538.90 (Parts for electrical control equipment) |

| Module Type | Digital Output, 16 points, DC sinking (NPN) |

| Signal I/O Types | Outputs: 16 x transistor outputs, sinking, 10–30 VDC |

| Power Requirements | Backplane powered (1746 chassis); external 10–30 VDC field supply required for loads |

| Communication Interfaces | 1746 SLC backplane interface (no front‑port comms) |

| Installation Method | Single‑slot module for 1746 chassis; panel or DIN‑rail mount via chassis |

| Operating Temperature | Typically 0 to 60 °C (32 to 140 °F) in a ventilated cabinet |

| Dimensions & Weight | Standard SLC 500 single‑slot form factor; approx. 145 × 35 × 140 mm; ~0.25 kg |

Application Fields

The 1746-OV16 fits well in brownfield and mid‑life SLC 500 plants where additional digital outputs are needed:

- Discrete machine control – solenoids, DC contactor coils, gates, diverters, and interlocks.

- Packaging and conveying – divert arms, pushers, brake/stop controls, and lamp towers.

- Water/Wastewater – valve actuation, dosing pump enable, and panel annunciation.

- Automotive and metals – fixture clamps, part present indicators, and e‑stop auxiliary signaling.

- Food & Beverage – low‑voltage actuators and wash‑down safe devices powered by external DC supplies.

A maintenance lead recently mentioned that swapping to 1746‑OV16s kept their legacy I/O map intact while moving field power to a cleaner 24 VDC supply—small change, big reliability gain.

Advantages & Value

- Proven reliability – SLC 500 modules have a strong track record in continuous‑duty plants.

- Form‑fit compatibility – No rework to chassis or controllers; minimizes risk and commissioning time.

- Clear diagnostics – Channel LEDs typically cut troubleshooting time during changeovers and maintenance.

- Cost control – Extends life of existing SLC assets; avoids early migration when expansion is the priority.

- Supportable – Documentation and replacement parts remain accessible for most installed bases.

Installation & Maintenance

- Cabinet & environment – Install in a properly grounded 1746 chassis within a ventilated control cabinet. Keep ambient 0–60 °C and avoid excessive vibration or moisture.

- Wiring – Use an external 10–30 VDC supply for loads. Because outputs are sinking (NPN), connect load to +V and return through the module’s output channel to 0 V.

- Inductive loads – Add flyback diodes or surge suppressors on solenoids, relays, and coils to protect transistors and reduce noise.

- Grounding & segregation – Separate DC power, I/O, and communication wiring where possible to limit interference.

- Routine checks – Periodically inspect terminal tightness, clean dust with dry air, and review output LED states during functional tests.

- Firmware & spares – No firmware on this I/O card; keep a spare module on hand for critical lines to minimize downtime.

Quality & Certifications

- Certifications: CE, UL, cUL (typical for SLC 500 I/O)

- Manufacturer’s warranty: typically 12 months from Rockwell Automation (model/region dependent)

- Supplied warranty from us: 365 days

Reviews

There are no reviews yet.