Description

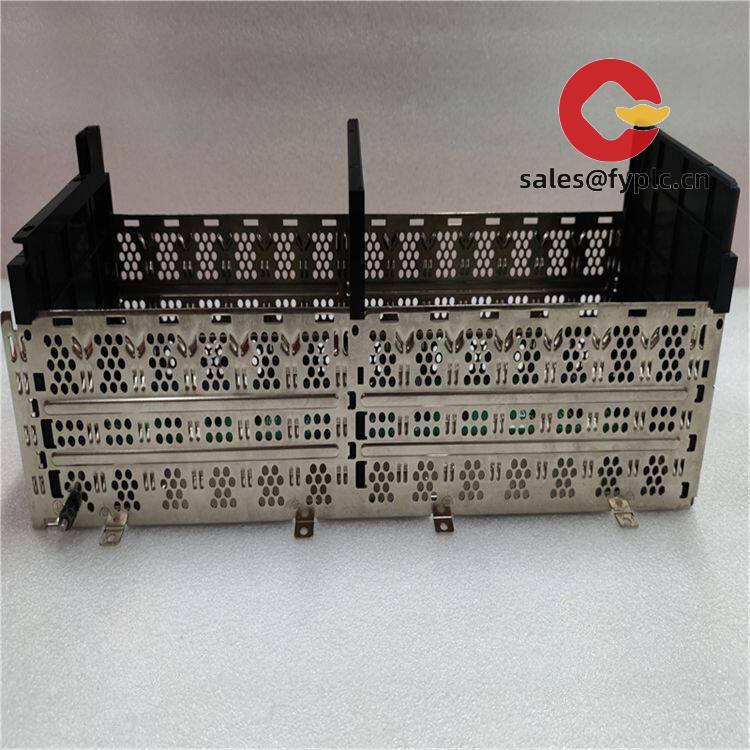

Allen‑Bradley 1756‑2WS – ControlLogix Wiring/Termination Accessory for Faster, Cleaner Panel Builds

The Allen‑Bradley 1756‑2WS sits within the ControlLogix 1756 ecosystem and is typically used as a wiring/termination accessory to simplify field connections around 1756 I/O. From my experience, maintenance teams pick it when they want consistent terminations across cabinets, less panel clutter, and quicker module swaps. It keeps your build neat and serviceable without forcing changes to your existing ControlLogix architecture.

You might notice that part numbers ending with “WS” in the 1756 family are often associated with wiring system components. That’s why many project BOMs call 1756‑2WS alongside standard 1756 chassis, power supplies, and I/O. If your goal is to streamline field wiring and reduce marshalling time, this accessory tends to pay for itself in saved labor and fewer wiring errors.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: fedex, UPS, DHL

Key Features

- ControlLogix fit – Works within the 1756 family, so it integrates cleanly with standard 1756 chassis and I/O practices.

- Faster terminations – Designed to simplify field wiring; typically shortens panel build time and reduces rework.

- Service-friendly layout – Clear labeling and consistent termination patterns make troubleshooting quicker for technicians.

- Robust industrial build – Suited for cabinet environments common to packaging, process, and material handling lines.

- Lifecycle support – Backed by the broad availability of Allen‑Bradley spares and documentation, which helps multi-plant standardization.

- Clean cable management – Helps keep wiring density under control, especially when I/O counts grow across multiple modules.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756‑2WS (ControlLogix wiring/termination accessory) |

| HS Code | 8537.10 (Programmable controller equipment and related assemblies) |

| Power Requirements | Not externally powered; used as a wiring/termination accessory in the 1756 system |

| Dimensions & Weight | Standard 1756 single‑slot footprint; typically ~145 × 35 × 140 mm, ~0.4 kg (varies slightly by revision) |

| Operating Temperature | 0 to 60 °C (cabinet installation; follow 1756 chassis derating and ventilation guidelines) |

| Signal Input/Output Types | N/A (wiring/termination accessory; pairs with ControlLogix I/O modules) |

| Communication Interfaces | N/A (uses the standard 1756 I/O connection scheme; no network port on the accessory) |

| Installation Method | Cabinet installation with ControlLogix 1756 chassis; single‑slot accessory format with standard module clearances |

Application Fields

The 1756‑2WS is well‑suited to installations where wiring density and uptime matter: high‑speed packaging machines, bottling and food lines, automotive body/assembly cells, water/wastewater plants, building materials, and general machine building. In many cases, engineering teams use it to standardize I/O terminations across lines, making migrations and expansions less disruptive.

Feedback from a packaging OEM: “We shaved roughly 20% off our panel wiring time after moving to the 1756 wiring accessory set. More importantly, weekend swap‑outs got easier for the maintenance crew.”

Advantages & Value

- Reliability – Industrial build quality aligned with ControlLogix practices; fewer loose conductors and less wiring stress.

- Compatibility – Works alongside standard 1756 modules, chassis, and power supplies without special hardware.

- Cost savings – Reduced installation hours and lower error rates typically offset the accessory cost on the first project.

- Maintainability – Clear labeling and consistent layout simplify troubleshooting and cut MTTR.

- Sourcing confidence – Mature 1756 platform with strong documentation and multi‑region availability.

Installation & Maintenance

- Cabinet & environment: Install in a 1756 chassis within an industrial control cabinet (IP54 or better is common). Keep ambient 0–60 °C with adequate airflow; avoid vibration and condensation.

- Clearances: Maintain standard ControlLogix module spacing; do not obstruct ventilation paths.

- Wiring: Use ferruled conductors where possible; follow torque specs and conductor size limits specified for 1756 accessories.

- Grounding & shielding: Route shield drains consistently to reduce noise; separate high‑voltage and signal cabling.

- Routine care: Periodically inspect terminals for loosening due to thermal cycling; dust off with dry, oil‑free air; verify labeling matches the project documentation.

- Firmware: Not applicable to the accessory itself; if used with smart I/O, keep module firmware current per your site’s change control.

Quality & Certifications

- Certifications: CE, c‑ULus listed; RoHS compliant (typical for 1756 family components)

- Manufacturer quality: Produced under ISO‑certified processes

- Warranty: 365‑day warranty from us; manufacturer’s standard policy also applies where applicable

Compatible and Supporting Components (Common Pairings)

- 1756‑A4/A7/A10/A13 – ControlLogix chassis, choose slot count to match system size.

- 1756‑PA72 / 1756‑PB72 – AC/DC power supplies that feed the 1756 backplane.

- 1756‑EN2T / 1756‑EN2TR – EtherNet/IP communication modules for controller and I/O networking.

- 1756‑TBS6H / 1756‑TBCH – Terminal bases often paired with I/O for spring‑clamp or screw terminations.

- 1756‑L7x controller family – Compact, high‑performance ControlLogix CPUs for mid‑to‑large machines.

If your project spec lists 1756‑2WS for cabinet builds or I/O panel standardization, we can align shipment to your FAT dates. Where drawings or photos are available, a quick cross‑check typically confirms compatibility within minutes.

Reviews

There are no reviews yet.