Description

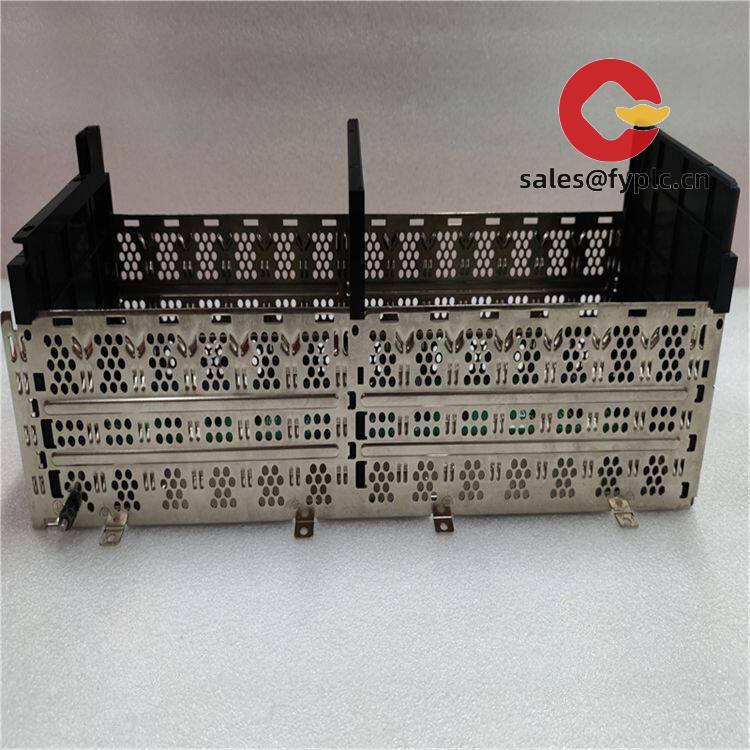

Allen-Bradley 1756-A13 ControlLogix 13‑Slot Chassis – A solid, scalable base for large ControlLogix systems

The Allen‑Bradley 1756-A13 is the 13‑slot ControlLogix chassis that many plant teams pick when they need room to grow without redesigning the cabinet. From my experience, it’s the “set it and forget it” backbone: passive backplane, reliable grounding, clean airflow, and straight‑forward panel mounting.

You might notice that it gives you plenty of flexibility—standard or redundant power supplies, any mix of 1756 controllers, communications, and I/O modules—so expansion typically stays painless.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- 13-slot standard-depth chassis – Ample space for controllers, communication modules, safety, and specialty I/O without reworking your enclosure.

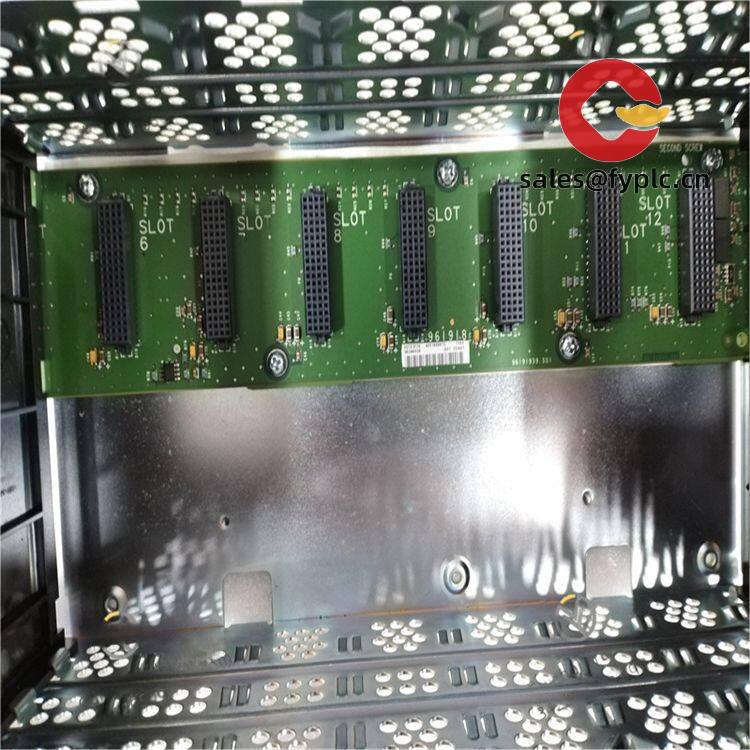

- Passive backplane, high reliability – No moving parts; the backplane simply distributes power and data between 1756 modules for long service life.

- Power supply flexibility – Works with standard or redundant 1756 power supplies (e.g., 1756-PA72/PA75 AC, 1756-PB72/PB75 DC, 1756-PA75R/PB75R redundant).

- Backward/forward compatibility – Typically supports legacy 1756 controllers and newer Logix 5570/5580 series modules in the same frame.

- Panel-mount simplicity – Straightforward installation in industrial cabinets; good cable access and grounding points help keep EMC in check.

- Built for harsh plant environments – Normal operation across typical 0…60 °C ranges; designed for industrial shock/vibration levels when properly mounted.

Technical Specifications

| Item | Specification |

|---|---|

| Brand / Model | Allen-Bradley 1756-A13 (ControlLogix 13-slot chassis) |

| HS Code | 8538.90 (Parts for switching/protection/control apparatus) |

| Power Requirements | Requires external 1756 series power supply; supports standard and redundant supplies (e.g., 1756-PA72/PA75 AC, 1756-PB72/PB75 DC, 1756-PA75R/PB75R) |

| Slots | 13 module slots (1 slot reserved for power supply bay on the left) |

| Operating Temperature | 0 to 60 °C (32 to 140 °F), non-condensing humidity per ControlLogix specs |

| Signal I/O Types | Backplane only; accepts 1756 discrete, analog, safety, motion, and specialty I/O modules |

| Communication Interfaces | None on chassis; communications via installed 1756 modules (e.g., EtherNet/IP, ControlNet, DeviceNet) |

| Installation Method | Panel mount in industrial enclosure; provides grounding points and mounting slots |

| Dimensions & Weight | Standard ControlLogix 13-slot chassis; approx. 517 mm (W) × 178 mm (H) × 145 mm (D); ≈ 3.5–3.9 kg (typical) |

Application Fields

The 1756-A13 is a good fit when the system needs more than a handful of modules or when future expansion seems likely. I’ve seen it widely used in:

- Process industries (chemicals, oil & gas, pharma) where redundant power and multiple network cards are common.

- Water & wastewater plants consolidating analog, discrete, and networked instrumentation in one frame.

- Food & beverage and packaging OEMs, often combining motion, safety, and high-speed I/O in a single chassis.

- Automotive and material handling lines that routinely add stations or networks over the lifecycle.

- Energy and utilities with large I/O counts and segmented network architectures.

Advantages & Value

- Capacity with headroom – 13 slots reduce the need for additional enclosures and wiring rework, which saves both panel space and labor.

- Compatibility that lowers risk – In many cases you can mix legacy and current 1756 modules, easing phased upgrades.

- Reliable lifecycle – Passive chassis design contributes to fewer field failures and predictable maintenance windows.

- Redundancy-ready – Support for redundant power supplies helps improve uptime in critical applications.

- Total cost control – Fewer cabinets, cleaner wiring, and simpler expansion typically cut total installed and lifecycle cost.

Installation & Maintenance

- Cabinet & environment – Mount on a rigid backplate inside an industrial enclosure (NEMA/IP rated as needed). Keep clear airflow; avoid conductive dust and corrosive atmospheres.

- Grounding & wiring – Bond the chassis to panel ground using the provided lug. Route power and network cabling with proper segregation to minimize electrical noise.

- Power sizing – Select a 1756 power supply with adequate backplane power for all installed modules and foreseeable expansion; consider redundant supplies for critical systems.

- Clearances – Allow service clearance top/bottom for module insertion/removal and air movement; secure all module latches firmly.

- Routine care – Periodically check mounting fasteners and ground connections; vacuum dust (no compressed air). Keep controller/module firmware current during planned downtime.

- Spare strategy – It appears that keeping at least one spare chassis per site helps shorten recovery time after panel incidents.

Quality & Certifications

- Conformity: CE, cULus Listed, RoHS (typical for ControlLogix chassis)

- Manufacturer warranty: typically 12 months limited (factory)

- Our warranty: 365 days

Recommended Compatible Components

- Power supplies – 1756-PA72 / 1756-PA75 (AC), 1756-PB72 / 1756-PB75 (DC), 1756-PA75R / 1756-PB75R (redundant).

- Controllers – 1756-L7x (Logix 5570), 1756-L8xE (Logix 5580) series.

- Communications – 1756-EN2T/EN3TR (EtherNet/IP), 1756-CNB(C) (ControlNet), 1756-DNB (DeviceNet), and others.

- I/O modules – 1756 discrete (IB/OB), analog (IF8/OF8), safety (1756-IB16S/OBV8S), motion interface modules.

Quick customer note: a packaging OEM recently moved from a 10‑slot to a 1756-A13 to add an extra EtherNet/IP card, a safety output module, and two analog inputs for a new recipe skid—no cabinet redesign, no new backplane wiring. That kind of incremental upgrade is where this chassis usually shines.

Reviews

There are no reviews yet.