Description

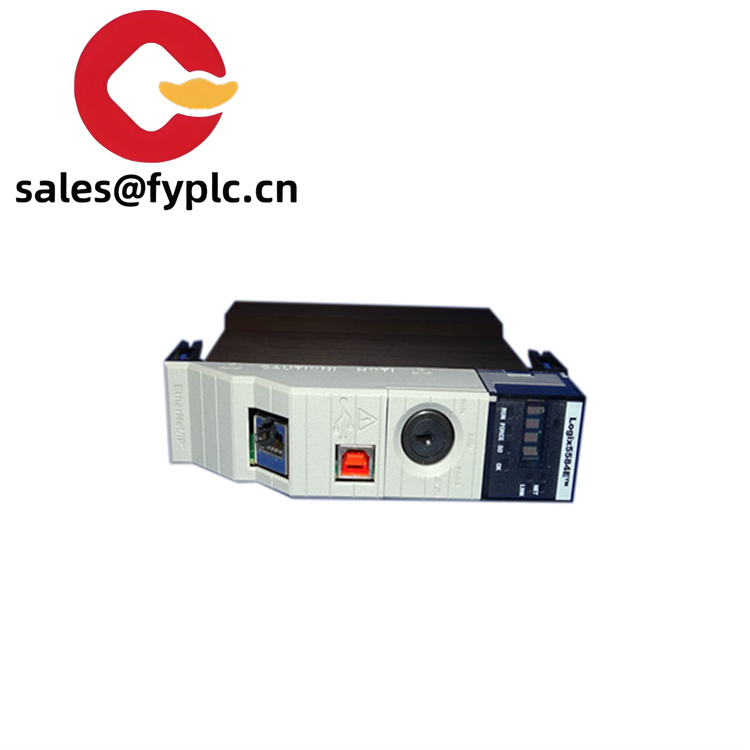

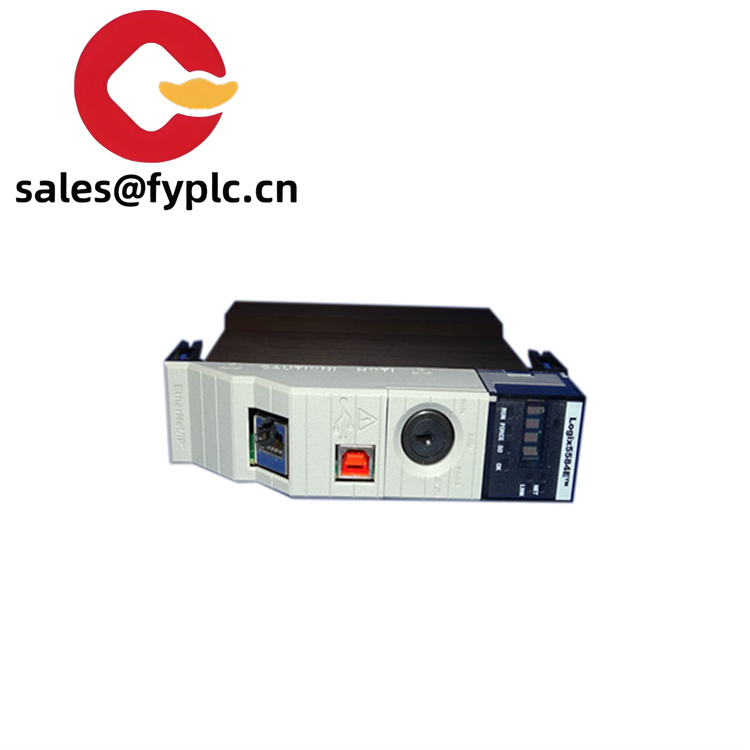

Allen Bradley 1756-L84E Programmable Automation Processor Controller Module

1756-L84ES-4

The 1756 – L84E is engineered to manage complex industrial automation applications across a wide array of industries. From the fast – moving production lines in automotive manufacturing to the precise processes in the pharmaceutical industry, this controller has the versatility to adapt. It can be the central command in a large – scale manufacturing plant, coordinating the movement of robotic arms, conveyor belts, and other machinery to ensure smooth production. In power generation facilities, it plays a crucial role in controlling turbines and generators, maintaining a stable power supply. Its presence in chemical processing plants helps in regulating reactions, ensuring safety and optimal product quality.

| Label |

Specification |

| Model Number |

1756 – L84E |

| Brand |

Allen – Bradley |

| Type |

Programmable Automation Controller |

| Input Voltage |

24 V DC |

| Operating Temp |

-40°C to +70°C |

| Communication Method |

Ethernet/IP, ControlNet, DeviceNet, Profinet (varies by configuration) |

| Mounting |

Rack – mountable in Controllogix 1756 chassis |

| Weight |

Approximately [X] kg (specify exact weight if available) |

| Certifications |

UL, cUL, CE, ATEX (if applicable) |

| Dimensions |

[Length] x [Width] x [Height] mm |

| IP Rating |

IP20 (protected against solid objects like dust) |

| Protocols Supported |

CIP Safety, EtherNet/IP, ControlNet, DeviceNet, and more depending on setup |

The Allen – Bradley 1756 – L84E offers a plethora of functional strengths that make it stand out in the industrial landscape. Its high – performance processor, combined with a substantial 20 MB of user memory, allows it to handle a vast amount of data and complex control algorithms in real – time. Whether it’s processing sensor inputs to make split – second decisions or executing control commands for actuators, the 1756 – L84E does so with remarkable speed and accuracy.

1756-L84E-3

This controller is a master of connectivity, boasting multiple communication interfaces. With options like Ethernet/IP, ControlNet, and DeviceNet, it can easily communicate with a wide range of industrial devices. This interoperability ensures seamless data transfer between the controller, sensors, actuators, and other components in the automation system. For example, in a smart factory setup, the 1756 – L84E can receive data from hundreds of sensors placed throughout the production floor, analyze this data, and then send out control signals to the relevant actuators, all in a matter of milliseconds.

The 1756 – L84E is built to last. Its modular design not only makes installation and maintenance a breeze but also ensures high reliability. The use of conformal coating protects the internal components from harsh environmental factors such as dust, moisture, and chemical vapors, making it suitable for use in even the most challenging industrial environments.

The 1756 – L84E has found its place in numerous industrial use cases, delivering significant value. In the automotive manufacturing industry, it’s the brain behind the highly – automated assembly lines. It controls the precise movements of robotic arms as they weld, paint, and assemble car parts. By integrating with other devices on the production line through Ethernet/IP, it enables real – time monitoring and adjustment of the manufacturing process. This not only improves production efficiency but also reduces the number of defective products, saving both time and money.

In the water and wastewater treatment sector, the 1756 – L84E is used to manage the entire treatment process. It controls pumps, valves, and other equipment to ensure the proper filtration, disinfection, and chemical dosing of water. With its ability to communicate with various sensors in the treatment plant, it can monitor water quality parameters in real – time and adjust the treatment process accordingly, providing a reliable and safe water supply.

Several models are related to the Allen – Bradley 1756 – L84E.

- 1756 – L81E – A more basic version with less memory and processing power, suitable for smaller – scale industrial applications where cost – effectiveness is a key factor.

- 1756 – L82E – Offers a balance between performance and cost, with a smaller user memory compared to the 1756 – L84E but still sufficient for many mid – sized industrial control tasks.

- 1756 – L83E – Features enhanced communication capabilities, such as additional Ethernet ports, which is beneficial for industrial setups that require extensive network connectivity.

- 1756 – L85E – Designed for applications with even more demanding processing requirements, offering increased memory and a faster processor.

- 1756 – L86E – A variant with advanced diagnostic features, allowing for quicker identification and resolution of any issues that may arise during operation, thus minimizing downtime.

Installing the Allen – Bradley 1756 – L84E requires careful attention to detail. When mounting it in the Controllogix 1756 chassis, ensure that the chassis is properly grounded to prevent electrical interference. All electrical connections should be made as per the provided wiring diagrams, and the power supply should be stable and within the specified 24 V DC range. For communication connections, use high – quality shielded cables to avoid signal loss and interference. When programming the 1756 – L84E, use Rockwell Automation’s Studio 5000 software, which provides an intuitive interface for creating and deploying control programs.

1756-L84E

For long – term maintenance, regular inspections are crucial. Check for any signs of physical damage, such as cracks in the enclosure or loose connections. Monitor the controller’s performance metrics, including processor load, memory usage, and communication error rates. Keep the controller’s firmware up – to – date to benefit from the latest features, bug fixes, and security enhancements. Periodically clean the controller to remove dust and debris, especially if it’s installed in a dusty environment. It’s also a good practice to perform regular backups of the control programs and data stored in the controller to prevent data loss in case of hardware failures.

Click below to learn more:

Reviews

There are no reviews yet.