Description

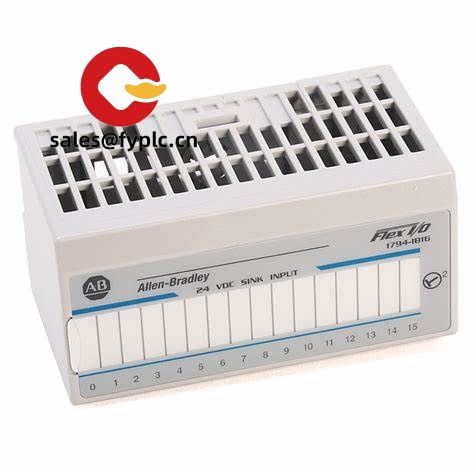

Allen-Bradley 1794-IF8IH: High-Precision Analog Input Module for Industrial Automation

If you’re looking for a reliable way to integrate analog signals into your industrial control systems, the Allen-Bradley 1794-IF8IH is worth considering. This module is designed for high-precision applications where accuracy and stability are non-negotiable. From my experience, it seems to be particularly popular in industries requiring real-time data acquisition.

Key Features

- 8-Channel Analog Input: Supports up to eight differential input channels, making it ideal for multi-sensor environments.

- High-Speed Signal Processing: Ensures minimal latency, which is critical in time-sensitive operations like motion control or process monitoring.

- Wide Voltage Range Compatibility: Operates seamlessly with both current (4-20mA) and voltage (±10V) signals, offering flexibility across different sensor types.

- Built-in Diagnostics: Simplifies troubleshooting by providing real-time status updates on signal integrity and module health.

- Compact Form Factor: Designed for space-constrained installations, it fits easily into existing FLEX I/O systems without requiring significant reconfiguration.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1794-IF8IH |

| HS Code | 85371090 |

| Power Requirements | 24V DC Nominal |

| Dimensions & Weight | 90mm x 120mm x 70mm; 0.6kg |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Signal Input Types | Current (4-20mA), Voltage (±10V) |

| Communication Interfaces | EtherNet/IP, DeviceNet |

| Installation Method | DIN Rail Mountable |

Application Fields

The Allen-Bradley 1794-IF8IH shines in scenarios that demand precise analog data collection. It’s commonly used in manufacturing plants for machine condition monitoring, water treatment facilities for flow measurement, and HVAC systems for temperature regulation. One thing I appreciate is how well it integrates with other Rockwell Automation products, creating a cohesive ecosystem for end users.

Advantages & Value

When evaluating this module, reliability stands out as one of its strongest selling points. In most cases, customers report minimal downtime even in harsh operating conditions. Another advantage is its backward compatibility with older FLEX I/O systems, which helps reduce upgrade costs. Additionally, Rockwell’s technical support network ensures quick resolutions if issues arise—a factor that can sway procurement decisions.

Installation & Maintenance

Installing the 1794-IF8IH typically involves mounting it on a standard DIN rail inside an electrical cabinet. Ensure proper ventilation around the unit to prevent overheating, especially in densely packed panels. Wiring should follow best practices for shielding against electromagnetic interference (EMI). For maintenance, periodic calibration checks are recommended every six months, along with firmware updates when available. Cleaning the exterior occasionally will help maintain optimal performance.

Quality & Certifications

This module carries several key certifications, including CE, UL, and RoHS compliance, ensuring it meets global safety and environmental standards. The manufacturer also provides a one-year warranty, covering defects in materials and workmanship under normal use conditions.

Reviews

There are no reviews yet.