Description

Allen-Bradley 1794-IT8 Thermocouple Input Module for Precision Temperature Monitoring

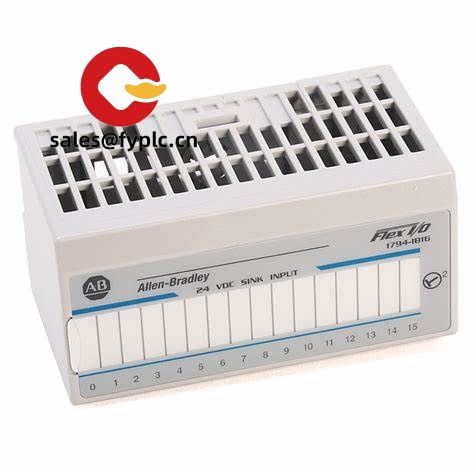

If you’re looking for a reliable solution to integrate thermocouple-based temperature monitoring into your industrial automation setup, the Allen-Bradley 1794-IT8 is worth considering. This module is part of the Flex I/O series and is designed to deliver accurate temperature readings in demanding environments. One thing I appreciate is its ability to handle up to eight thermocouple inputs, making it versatile for applications requiring multi-point temperature measurement.

Key Features

- Eight Thermocouple Inputs: Supports various types of thermocouples (J, K, T, E, R, S, B, N), giving you flexibility for different temperature ranges and materials.

- High Accuracy: The module provides precise temperature data with minimal signal drift, which seems to be a critical factor for process control systems.

- Integrated Cold Junction Compensation: Ensures reliable measurements by automatically compensating for ambient temperature changes at the terminal block.

- Compact Design: Its slim profile fits seamlessly into existing Flex I/O systems, saving valuable cabinet space.

- Diagnostics and Fault Detection: Built-in diagnostics help identify issues like open circuits or out-of-range temperatures, reducing downtime.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1794-IT8 |

| HS Code | 85389099 |

| Power Requirements | 24V DC Nominal (19.2 – 31.2V DC) |

| Dimensions & Weight | 3.5 x 2.5 x 3.0 inches, 0.6 lbs |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Signal Input/Output Types | Thermocouple Input (8 channels) |

| Communication Interfaces | DeviceNet, EtherNet/IP Compatible |

| Installation Method | DIN Rail Mountable |

Application Fields

The Allen-Bradley 1794-IT8 finds its place in industries where precision temperature control is paramount. For instance, in food processing plants, this module ensures that ovens and chillers maintain consistent temperatures to meet safety standards. Similarly, in chemical manufacturing, it helps monitor reaction vessels to prevent overheating or undercooling. From my experience, customers also use it in HVAC systems to optimize energy efficiency while maintaining comfort levels.

Advantages & Value

What sets the 1794-IT8 apart is its balance of performance and ease of integration. It typically integrates smoothly with other Allen-Bradley products, minimizing compatibility headaches. In most cases, users report significant cost savings due to reduced wiring needs compared to standalone thermocouple transmitters. Additionally, Rockwell Automation’s technical support network adds peace of mind, especially when troubleshooting complex installations.

Installation & Maintenance

For installation, ensure the module is mounted on a standard DIN rail inside an enclosure with adequate ventilation. Wiring should follow best practices for shielding and grounding to avoid noise interference. Routine maintenance includes periodic calibration checks using certified equipment and firmware updates via RSLogix 5000 or Studio 5000 software. Cleaning the terminals every six months can also extend the life of the device.

Quality & Certifications

This module carries key certifications such as CE, UL, and RoHS compliance, ensuring it meets global safety and environmental standards. The manufacturer offers a one-year warranty, covering defects in materials and workmanship under normal use conditions.

Order Placement Process and Guarantees: We guarantee delivery within one week for in-stock items and no more than one month for special orders. A 50% advance payment is required, with the remaining balance due before shipment. Express shipping options include FedEx, UPS, and DHL. All purchases come with a 365-day warranty.

Reviews

There are no reviews yet.