Description

Allen-Bradley 1900-65A: Compact and Reliable Industrial Control Solution

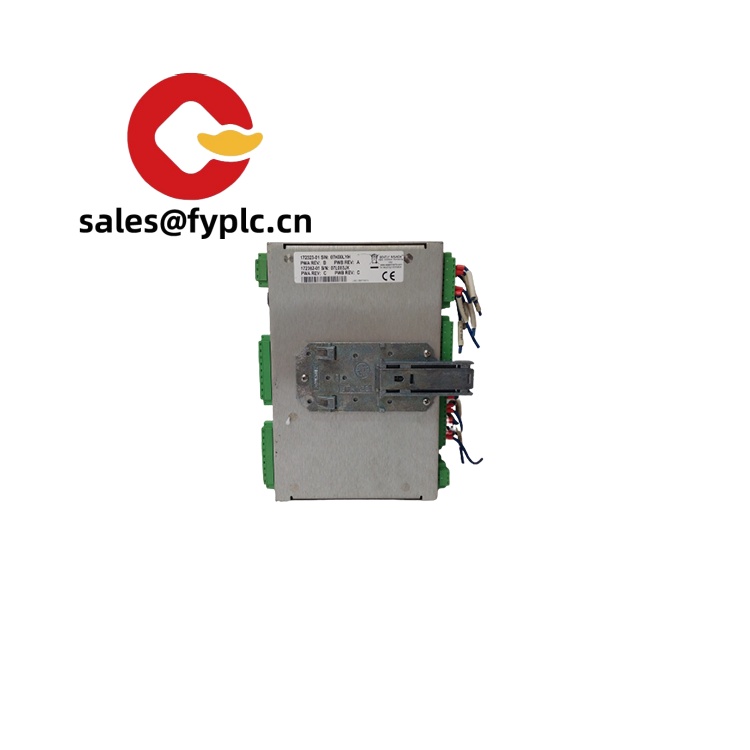

The Allen-Bradley 1900-65A is a versatile control module designed for industrial automation systems requiring precision, durability, and seamless integration. From my experience, this model is particularly well-suited for applications where space is limited but performance cannot be compromised.

Key Features

- Compact Design: Its small form factor makes it ideal for tight cabinet installations without sacrificing functionality.

- High-Speed Processing: The 1900-65A ensures rapid signal processing, which is critical for time-sensitive operations like conveyor belt control or robotic arm coordination.

- Robust Communication Interfaces: Equipped with Ethernet/IP and serial ports, it supports diverse connectivity options for modern industrial networks.

- User-Friendly Configuration: With intuitive software tools, setup and troubleshooting are straightforward, even for less experienced technicians.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1900-65A |

| HS Code | 85371090 |

| Power Requirements | 24V DC (±10%) |

| Dimensions & Weight | 120mm x 80mm x 40mm, 0.8kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Digital I/O, Analog I/O |

| Communication Interfaces | Ethernet/IP, RS-232 |

| Installation Method | DIN Rail Mounting |

Application Fields

The Allen-Bradley 1900-65A finds its place in various industries, including automotive manufacturing, food processing, and packaging lines. For instance, it seems to excel in scenarios requiring precise motion control, such as synchronizing multiple axes on assembly machines. In many cases, customers also deploy it in HVAC systems for energy-efficient building management.

Advantages & Value

One thing I appreciate about the 1900-65A is its balance between cost-effectiveness and performance. While not the cheapest option on the market, its reliability reduces downtime, which translates into long-term savings. Additionally, compatibility with existing Allen-Bradley ecosystems means you won’t need to overhaul your entire infrastructure—a significant advantage if you’re already invested in their platform.

Installation & Maintenance

For installation, ensure the cabinet meets standard DIN rail requirements and provides adequate ventilation to prevent overheating. Wiring should comply with local electrical codes, and it’s wise to double-check connections before powering up. Routine maintenance typically involves firmware updates (available via the manufacturer’s portal) and periodic cleaning of dust from vents. Calibration checks every six months can help maintain optimal performance.

Quality & Certifications

This product carries certifications such as CE, UL, and RoHS compliance, ensuring safety and environmental responsibility. The manufacturer offers a one-year warranty, covering defects in materials and workmanship under normal use conditions. You might notice that their technical support team responds promptly, which adds peace of mind during implementation.

Our Order Placement Process and Guarantees:

- Warranty period: 365 days

- Delivery time: Typically within 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment, full payment upon delivery

- Express delivery methods: FedEx, UPS, DHL

Reviews

There are no reviews yet.