Description

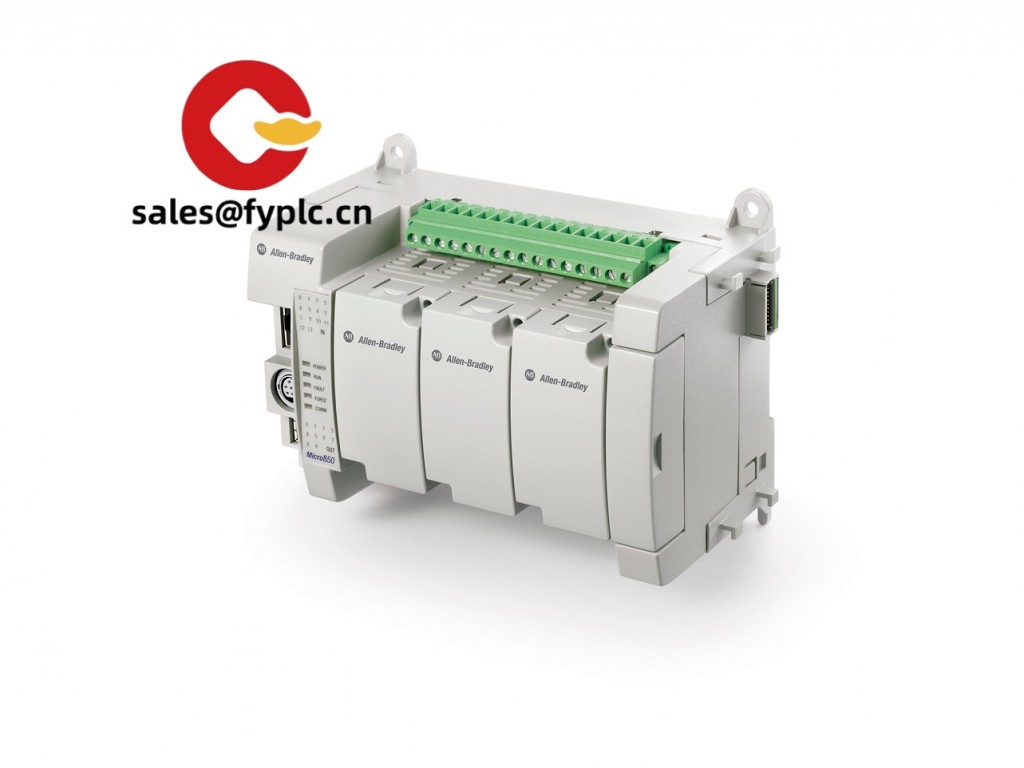

Allen-Bradley 2080-LC50-48QWB Micro850 Programmable Logic Controller

The Allen-Bradley 2080-LC50-48QWB is a versatile Micro850 PLC designed for small to medium-sized automation projects. With its robust feature set and compact design, it seems to strike a balance between performance and affordability. From my experience, this model works particularly well in applications like packaging lines, material handling systems, and HVAC control.

Key Features

- 48 I/O Points: This PLC offers 28 inputs and 20 outputs, making it ideal for applications requiring precise control over multiple devices.

- Built-In Ethernet Port: Enables seamless integration with other networked devices and supports protocols like EtherNet/IP for real-time communication.

- Pulse Train Outputs: Perfect for controlling stepper motors or servos in positioning tasks, which you might notice is a standout feature compared to similar models.

- Expandable Design: Supports up to seven expansion modules, allowing you to scale your system as your needs grow.

- User-Friendly Software: Compatible with Connected Components Workbench, simplifying programming and diagnostics.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 2080-LC50-48QWB |

| HS Code | 85371090 |

| Power Requirements | 24V DC (Nominal) |

| Dimensions & Weight | 128 x 90 x 70 mm, ~0.4 kg |

| Operating Temperature | 0°C to 55°C (32°F to 131°F) |

| Signal Input/Output Types | Digital Inputs, Relay Outputs |

| Communication Interfaces | EtherNet/IP, RS-232 Serial Port |

| Installation Method | DIN Rail Mounting |

Application Fields

This PLC typically finds its place in industries where precision and flexibility are key. For instance, it’s widely used in conveyor systems to manage sorting operations efficiently. In food processing plants, the controller’s ability to handle high-speed digital signals ensures accurate timing for filling machines. One thing I appreciate is how well it performs in environments that require frequent firmware updates—its Ethernet connectivity makes maintenance hassle-free.

Advantages & Value

For procurement teams, reliability is often top of mind, and the Micro850 doesn’t disappoint. Its compatibility with existing Rockwell Automation ecosystems reduces integration headaches, while the expandable architecture means fewer replacements down the road. Cost savings come into play too—fewer components mean less wiring and lower installation costs. Plus, Rockwell’s technical support team has always been responsive when troubleshooting issues.

Installation & Maintenance

Installing the 2080-LC50-48QWB is straightforward if you follow a few guidelines. It requires a standard DIN rail setup inside an electrical cabinet with adequate ventilation to prevent overheating. Wiring should comply with local regulations, especially since relay outputs can generate heat during prolonged use. Routine maintenance includes periodic cleaning of dust from vents and ensuring all connections remain secure. Firmware updates through the software keep the system running smoothly, though they’re not something you’ll need to do very often.

Quality & Certifications

The Allen-Bradley 2080-LC50-48QWB carries certifications such as CE, UL, and RoHS compliance, ensuring it meets global safety and environmental standards. The manufacturer backs it with a one-year warranty, which provides peace of mind for critical applications. If anything goes wrong within the warranty period, replacement or repair services are available without unnecessary delays.

Reviews

There are no reviews yet.