Description

Allen-Bradley 2085-IF8: Compact Analog Input Module for Industrial Automation

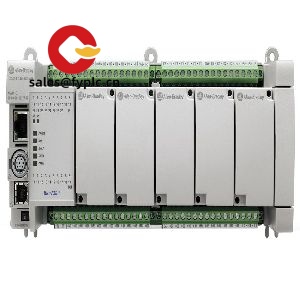

The Allen-Bradley 2085-IF8 is a compact analog input module designed to seamlessly integrate into Micro800 PLC systems. It provides reliable performance in industrial environments where precision and flexibility are critical. From my experience, this module seems to be a go-to choice for engineers looking to expand their system’s analog capabilities without overcomplicating setup or breaking the budget.

Key Features

- 8 Analog Inputs: Supports up to eight differential or single-ended inputs, making it versatile for various sensor types like temperature probes or pressure transducers.

- High Resolution: Offers 16-bit resolution, ensuring accurate data acquisition even in demanding applications.

- Wide Voltage Range: Compatible with both current (0–20 mA) and voltage (±10 V) signals, giving you flexibility in connecting field devices.

- Plug-and-Play Design: Simplifies installation by integrating directly into Micro800 controllers without additional configuration tools.

- Diagnostics Support: Built-in diagnostics help identify wiring issues or signal anomalies quickly, reducing downtime.

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 2085-IF8 |

| HS Code | 85371090 |

| Power Requirements | 24V DC (nominal) |

| Dimensions & Weight | 90mm x 70mm x 65mm, ~250g |

| Operating Temperature | -20°C to +65°C |

| Signal Input Types | Voltage (±10V), Current (0–20mA) |

| Communication Interfaces | Embedded via Micro800 backplane |

| Installation Method | DIN rail mounting |

Application Fields

This module finds its niche in industries that demand precise monitoring and control of analog signals. You might notice that it’s particularly well-suited for HVAC systems, water treatment plants, and manufacturing lines where sensors measure variables such as flow rates, temperatures, or pressures. In many cases, customers use the 2085-IF8 alongside other Micro800 modules to create scalable solutions tailored to their specific needs.

Advantages & Value

One thing I appreciate about the 2085-IF8 is how it balances cost-effectiveness with reliability. Its compatibility with Micro800 systems ensures minimal integration headaches, while the plug-and-play design saves on engineering time. For procurement teams, this translates into lower upfront costs and reduced long-term maintenance expenses. Additionally, Rockwell Automation’s robust technical support network can be a lifesaver if you ever run into challenges during deployment.

Installation & Maintenance

Installing the 2085-IF8 typically involves DIN rail mounting inside an electrical cabinet. Ensure proper ventilation around the unit to prevent overheating, especially in high-temperature environments. Wiring should follow standard practices, but double-check polarity for current loops to avoid misconfigurations. Routine maintenance includes periodic firmware updates through Connected Components Workbench software and inspecting terminal connections for corrosion or looseness.

Quality & Certifications

The Allen-Bradley 2085-IF8 carries certifications like CE, UL, and RoHS compliance, underscoring its adherence to global safety and environmental standards. The manufacturer offers a standard one-year warranty, which aligns with our company’s guarantee policy. If any issues arise within the warranty period, we’ll work closely with you to resolve them promptly.

Reviews

There are no reviews yet.