Description

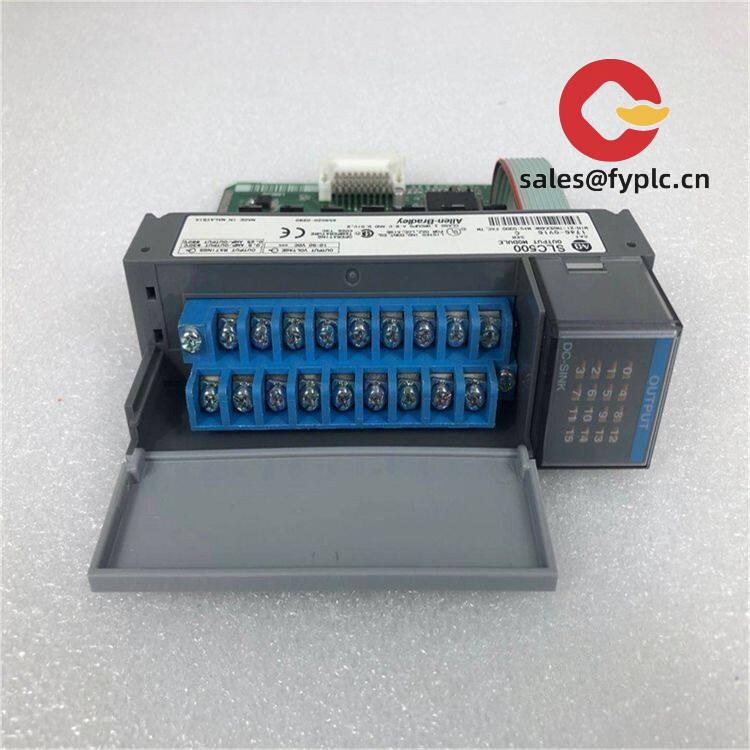

Allen‑Bradley 2098-DSD-020X Ultra3000 Servo Drive – Fast, Accurate Motion at 200–240 VAC

The Allen‑Bradley 2098-DSD-020X is part of the Ultra3000 family—a robust digital servo drive that’s typically chosen for high-repeatability indexing, pick‑and‑place, packaging axes, and retrofit projects where reliability matters. One thing I appreciate is how straightforward it is to commission with UltraWare over RS‑232, while still giving you flexible control modes (position, velocity, torque) and familiar I/O for real‑world machines.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In‑stock items typically ship in 1 week; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Digital servo control, Ultra3000 platform – Stable, proven design that fits many legacy and current machine upgrades.

- Flexible control modes – Position, velocity, and torque modes; well‑suited for indexing conveyors, feeders, and cut‑to‑length lines.

- Indexing capability – Handles point‑to‑point moves without a full PLC motion module in many cases, reducing system cost.

- RS‑232 setup with UltraWare – Quick parameterization, trending, and diagnostics; you might notice commissioning time drops on repeat jobs.

- Versatile I/O – Step/Direction command support, ±10 V analog reference, registration (marker) input, and encoder emulation (A/B/Z) for host devices.

- Encoder feedback compatibility – Supports incremental encoder feedback typical of Allen‑Bradley MPL/MPF servo motors.

- 200–240 VAC operation – Common plant power, typically single‑ or three‑phase input depending on installation.

- Panel‑mount, compact footprint – Fits standard enclosures; from my experience, heat dissipation is manageable with modest spacing and airflow.

Technical Specifications

| Brand / Model | Allen‑Bradley 2098-DSD-020X (Ultra3000 Digital Servo Drive) |

| HS Code | 8504.40 (Static converters – AC motor drives/servo drives) |

| Power Requirements | 200–240 VAC, 50/60 Hz; single‑ or three‑phase input (per installation) |

| Operating Temperature | 0 to +50 °C (cabinet‑mounted), non‑condensing environment |

| Signal Input/Output Types | Step/Direction, ±10 V analog command, digital I/O for enable/limits/home, registration input, encoder emulation (A/B/Z) |

| Communication Interfaces | RS‑232 for configuration/diagnostics via UltraWare (no fieldbus on “‑X” variant) |

| Installation Method | Panel/cabinet mounting, vertical orientation; IP20 (enclosed), provide top/bottom clearance for cooling |

| Dimensions & Weight | Approx. 311 × 90 × 184 mm (H×W×D); approx. 3.6–4.0 kg (typical for this frame size) |

Application Fields

This model seems to be a good fit for mid‑power axes where smooth positioning and quick setup matter. Typical uses:

- Packaging: indexing belts, seal‑jaw axes, rotary knives

- Electronics assembly: pick‑and‑place, feeders, labelers

- Printing & converting: registration control, slitting, unwinds/rewinds

- General machinery: test stands, small machine tools, material handling

Advantages & Value for Procurement

- Reliable and familiar – Widely deployed Ultra3000 platform; technicians often know it, which shortens downtime.

- Compatibility – Works well with Allen‑Bradley MPL/MPF servo motors and 2090 series power/feedback cables.

- Cost‑effective retrofits – In many cases you keep existing I/O and wiring, avoiding a full motion system redesign.

- Clear diagnostics – RS‑232 with UltraWare makes tuning and fault tracing practical on the shop floor.

Installation & Maintenance

- Cabinet & ventilation – Mount vertically in a clean, dry enclosure; allow top/bottom clearance, and provide airflow or a fan plate if ambient approaches 50 °C.

- Wiring practices – Use shielded motor/feedback cables (2090 series). Keep feedback and signal wiring separate from mains to reduce noise.

- Grounding & safety – Bond PE ground with low impedance. Verify STO/enable circuits before energizing. De‑energize and wait for DC bus discharge before servicing.

- Tuning & calibration – Run basic autotune in UltraWare, then fine‑tune gains under load. Check encoder direction and scaling.

- Routine care – Quarterly dust removal, terminal retorque checks, and event log review. Firmware updates via RS‑232 where applicable.

Quality & Certifications

- Typically CE marked and UL/cUL recognized for industrial control equipment

- RoHS compliance may depend on production revision; documentation can be provided upon request

- Standard warranty: 12 months (365 days)

Commonly Paired Accessories (for smoother commissioning)

- 2090 series power and feedback cables (e.g., 2090-XXNP… for power, 2090-UXNFB-… for feedback)

- MPL/MPF servo motors sized to the 020X current class

- Panel cooling fans or filter fans where cabinet ambient is high

From my experience, the 2098-DSD-020X is a dependable mid‑range Ultra3000 option. If you’re replacing an existing unit, share your motor model and supply details—matching feedback and cable sets up front typically prevents 90% of commissioning hiccups.

Reviews

There are no reviews yet.