Description

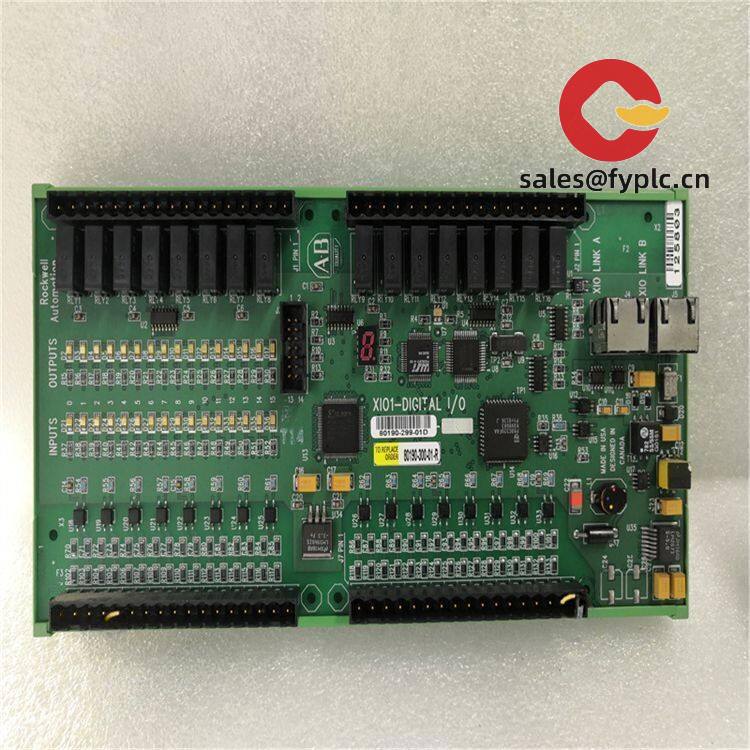

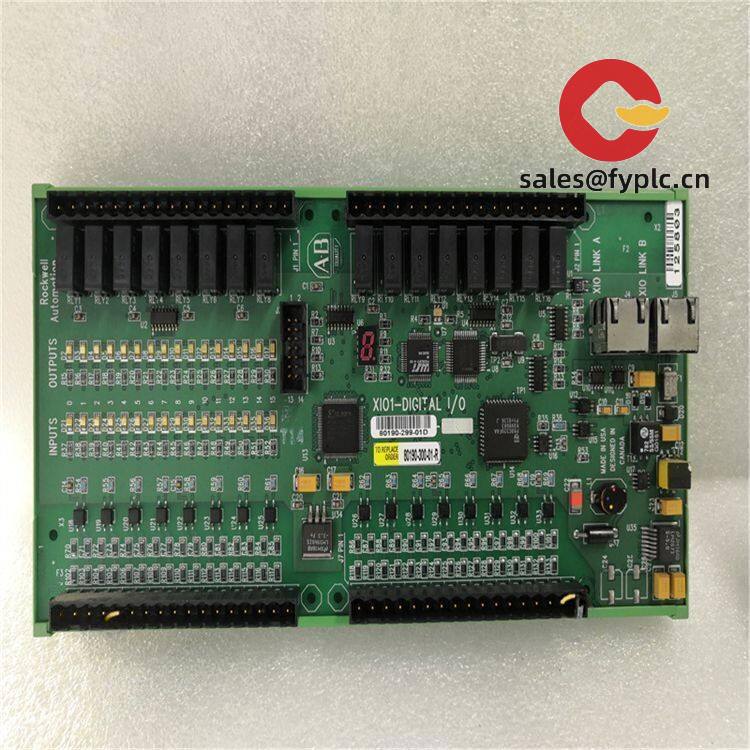

Allen-Bradley 80190-300-01-R – OEM Remanufactured Control Board for Motion/Drive Systems

The Allen‑Bradley 80190-300-01-R is an OEM remanufactured board-level assembly designed as a direct, drop‑in replacement inside Allen‑Bradley motion control and drive platforms. From my experience, this assembly is typically found in installed bases using Allen‑Bradley servo drive technology, and in many cases appears within Bulletin 1394 S‑Class multi‑axis systems. If you’re maintaining a production line and need a fast, like‑for‑like replacement to get a machine back online, this model is built for exactly that scenario—stable, compatible, and electrically vetted to OEM standards.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express Options: FedEx, UPS, DHL

You might notice that this process is set up for maintenance teams who need predictability—clear timelines, clear terms, and a warranty that actually covers a full production season in most cases.

Key Features

- OEM Remanufactured (-R) Assembly: Supplied to Allen‑Bradley standards for fit, form, and function; ideal as a like‑for‑like spare.

- Drop‑in Replacement: No mechanical modifications; aligns with the original mounting points and keyed connectors.

- Stable Integration: Interfaces with the host drive/controller backplane; no separate power supply required.

- Production‑Ready: Typically shipped ESD‑safe and function‑tested, reducing commissioning time on site.

- Traceability: Markings and revision details support maintenance records and audit needs.

- Serviceability: Board‑level swap can shorten downtime versus full unit replacement, especially on legacy lines.

Technical Specifications

| Brand / Model | Allen‑Bradley 80190-300-01-R |

| HS Code | 8538.90.00 (Parts for electrical control/switching apparatus) |

| Power Requirements | Powered internally by the host controller/drive backplane; typical logic rail includes +5 VDC (no external supply). |

| Dimensions & Weight | Board‑level OEM form factor; weight ≈ 0.45 kg (varies slightly by revision). |

| Operating Temperature | 0 to 55 °C (typical for Allen‑Bradley drive electronics in ventilated enclosures) |

| Signal I/O Types | Internal low‑voltage logic via backplane; feedback/command lines as defined by the host system (e.g., encoder/resolver feedback within the chassis, where applicable). |

| Communication Interfaces | Internal edge/ribbon connectors inside the host drive/controller; no external user port on the board itself. |

| Installation Method | Field‑replaceable module mounted inside the host unit; screw‑fixed with keyed connectors; observe ESD handling. |

Application Fields

This board is used as an internal control/processing assembly in Allen‑Bradley motion and drive systems—commonly seen in legacy and mid‑life assets. Typical applications include:

- Packaging and Converting: Web handling, tension control, and multi‑axis registration.

- Machine Tool & CNC: Precise axis control for milling, grinding, and routing cells.

- Material Handling: Coordinated servo axes for pick‑and‑place, palletizing, or gantry systems.

- Printing & Labeling: Synchronization of feeders, nip rolls, and cutters.

- Pharmaceutical & Food: Servo‑driven filling, capping, and inspection mechanisms.

One thing I appreciate is how maintenance teams often keep a spare like this on the shelf; when a line trips, a board swap can bring a cell back within an hour instead of waiting on a full drive replacement.

Advantages & Value

- Reliability: OEM reman with functional testing typically reduces the risk of recurring faults.

- Compatibility: Matches the original mechanical and electrical interface—no rewiring in most cases.

- Cost & Downtime Savings: Board‑level replacement is often more economical and faster than replacing an entire chassis.

- Traceable Lifecycle: Revision labeling helps align spares strategy across multiple lines/sites.

- Supportable: Works within established Allen‑Bradley platforms where documentation and field expertise are widely available.

Installation & Maintenance

- Environment: Install inside a clean, ventilated industrial enclosure (typically to NEMA/IEC cabinet standards) with ambient 0–55 °C and non‑condensing humidity.

- ESD Precautions: Use a grounded wrist strap and ESD mat; handle by edges only.

- Wiring/Connectors: Power down and lock out the host unit; verify keyed connectors and cable seating; check for damaged pins before power‑up.

- Cooling & Airflow: Keep filters clean and fans operational to maintain thermal margins.

- Routine Care: Every 6–12 months, gently remove dust with dry, oil‑free air; inspect connectors and standoffs; review event logs in the host controller.

- Firmware/Parameters: If the host platform uses board‑resident configuration, back up parameters before swap; restore and validate axis operation after installation.

Quality & Certifications

As an OEM remanufactured assembly, the 80190-300-01-R is built and tested to Allen‑Bradley quality practices. Compliance of the overall machine remains with the host system, which typically carries certifications such as CE and UL/cUL when installed per the manufacturer’s instructions. RoHS applicability may depend on the specific revision. Standard warranty is 365 days.

Notes on Compatibility and Supporting Components

This assembly is intended to be used within its designated Allen‑Bradley host. In many installed bases, it appears alongside multi‑axis servo modules, feedback interfaces, and internal backplane cabling. If you’re planning a maintenance window, it’s wise to have complementary spares on hand—such as the relevant internal ribbon cables, feedback/encoder leads, and cooling fans that serve the same bay. If you share the exact host catalog number, we can map this board to the slot location and confirm revision compatibility before shipment.

Reviews

There are no reviews yet.