Description

Allen‑Bradley 80190-580-01-R – OEM Controller PCB Assembly for Reliable Legacy PLC Maintenance

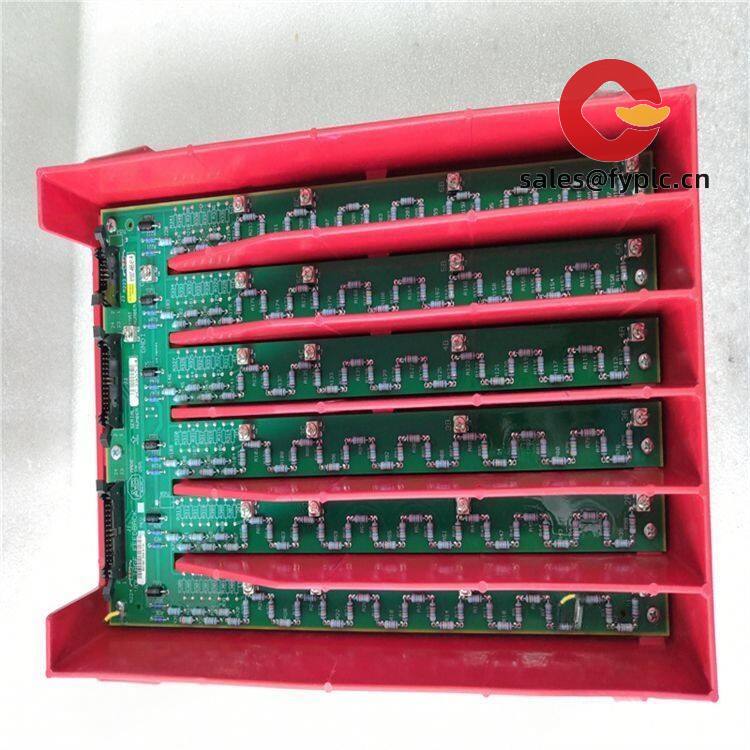

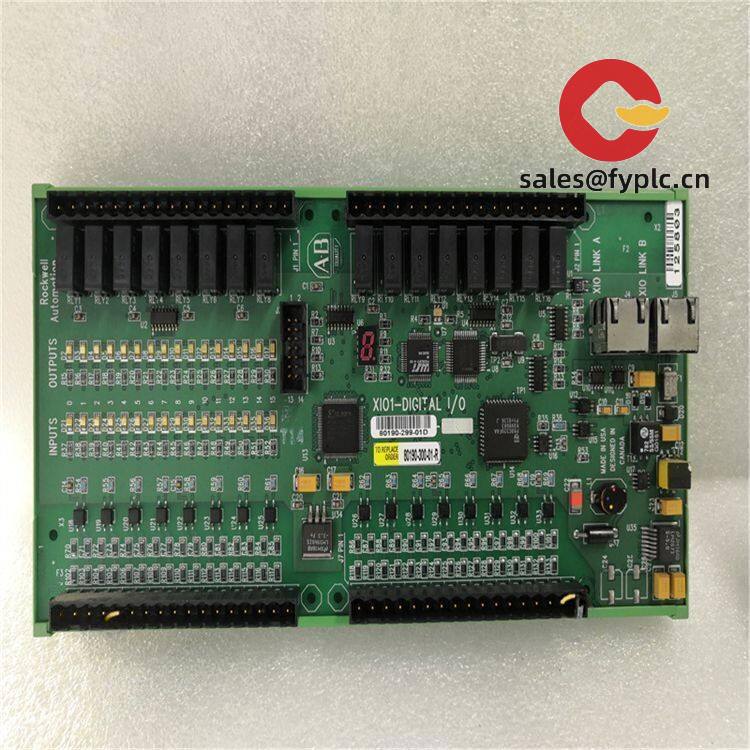

The Allen‑Bradley 80190-580-01-R is an OEM printed circuit board assembly typically used inside legacy Rockwell Automation controllers and racks. From my experience, plants keep this part on the shelf as an MRO spare to shorten unplanned downtime—especially where a full migration isn’t on the table this year. It’s designed to be backplane-powered, with no field wiring, making it a straightforward board-level replacement when you need to get a system back online quickly.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- OEM board-level assembly – Allen‑Bradley part number 80190-580-01-R, intended for use inside compatible Rockwell Automation controller hardware.

- Backplane powered – No separate power input; the host controller supplies the logic rails, which simplifies replacement.

- Drop-in service part – Fits into the original mechanical points (standoffs/edge connector) for fast swap during maintenance windows.

- Revision-conscious sourcing – Matching hardware revisions can be arranged, which in many cases helps avoid firmware mismatch or requalification headaches.

- ESD-safe handling and packaging – Shipped in antistatic protection to maintain board integrity during transit.

- Focused on uptime – Ideal for plants extending the lifecycle of legacy Allen‑Bradley PLC platforms while planning structured migrations.

Technical Specifications

| Brand / Model | Allen‑Bradley 80190-580-01-R |

| Product Type | OEM controller PCB assembly (board-level spare) |

| HS Code | 8538.90 – Parts suitable for apparatus of 8535/8536/8537 |

| Power Requirements | Backplane powered by host controller; typically logic-level rails (e.g., 5 VDC) |

| Operating Temperature | Follows host controller specification; typically 0 to 60°C, non‑condensing |

| Signal I/O Types | Internal signals only via edge/backplane; no direct field I/O terminals |

| Communication Interfaces | Proprietary backplane interface to the host controller/rack |

| Installation Method | Internal board replacement; secured by standoffs/screws and backplane connector per service manual |

Application Fields

Plants with a sizable installed base of Allen‑Bradley legacy PLC hardware typically use the 80190-580-01-R as a maintenance spare. You might notice it most in:

- Utilities and water/wastewater – controller board swap to restore a treatment line

- Oil & gas and chemicals – rapid replacement during a turnaround to keep units on spec

- Food & beverage and packaging – minimizing downtime on critical packaging PLCs

- Metals, mining, pulp & paper – lifecycle extension where migration windows are tight

A maintenance manager recently shared that having a matched‑revision board on hand saved them a weekend of troubleshooting after a controller fault—simple swap, quick boot, and the line was back up within an hour.

Advantages & Value

- Reliability – Genuine Allen‑Bradley hardware tends to integrate cleanly with the host system.

- Compatibility – Revision-conscious supply helps in most cases to align with existing firmware and rack configurations.

- Cost savings – Extends system life without immediate capex for a full migration.

- Lead time – In-stock units ship in about a week, with a clear latest-ship commitment.

- Support – Assistance with part identification and cross-revision selection upon request.

Installation & Maintenance

- Power down the system and follow lockout/tagout. Observe ESD precautions (wrist strap, antistatic mat).

- Open the host controller/rack enclosure, remove the failed board, and inspect the backplane edge connector for oxidation or debris.

- Seat the 80190-580-01-R firmly on the connector and secure with standoffs/screws as originally installed.

- If the board interacts with firmware or NVRAM, verify revision alignment and load the appropriate image or configuration, if applicable.

- Restore power and run controller diagnostics; confirm normal status indicators and process signals.

Preventive tips: keep cabinets ventilated and within the host controller’s rated temperature (typically 0–60°C), avoid moisture/condensation, clean dust with dry air periodically, and verify backplane connectors remain tight. Having a known‑good spare on site often pays for itself after a single unplanned outage.

Quality & Certifications

- Designed for use within Allen‑Bradley controller families that are CE and UL listed as complete assemblies.

- Manufacturer quality systems are typically ISO 9001 compliant.

- RoHS status can vary by hardware revision for legacy parts; we can check specific lots on request.

- Warranty: 365 days from delivery.

Reviews

There are no reviews yet.