Description

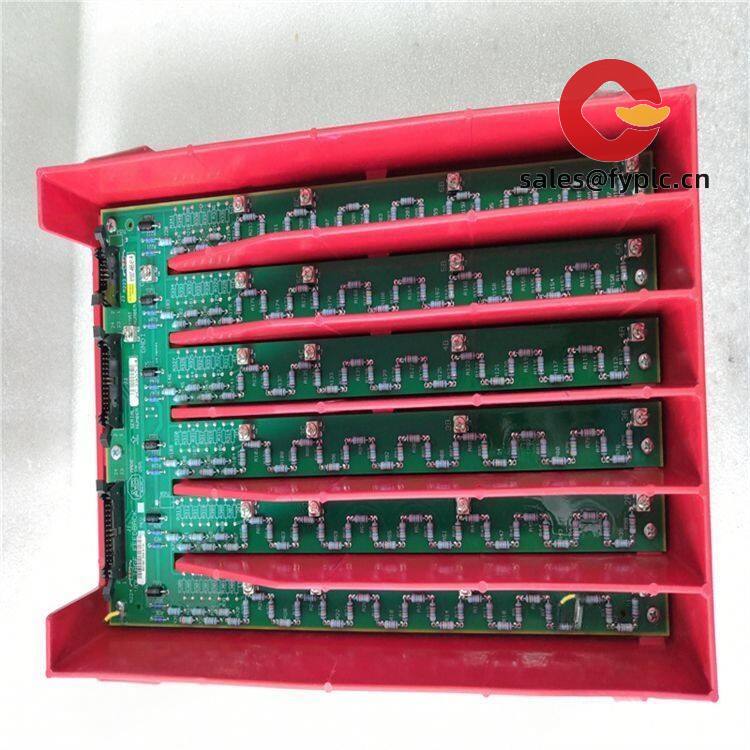

Allen‑Bradley 81007-465-51-R Industrial Control Board – Reliable OEM replacement for legacy Rockwell systems

The Allen‑Bradley 81007-465-51-R appears to be an OEM board-level assembly used inside selected Rockwell/Allen‑Bradley control equipment. From my experience, the “-R” suffix typically indicates a factory-repaired or remanufactured variant, and the “-51” portion points to a particular build or revision level. If you’re maintaining installed Allen‑Bradley assets and need a drop‑in board to restore a down line, this model is the kind of spare that gets equipment running again without re-engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage, parts and workmanship.

- Lead time: In‑stock items ship in about 1 week; no more than 1 month at the latest.

- Payment: 50% advance payment; full payment prior to delivery.

- Express options: FedEx, UPS, DHL.

Key Features

- OEM form‑fit replacement: Designed to seat in the original Allen‑Bradley mounting points and connectors, so you avoid mechanical rework.

- Backplane‑powered: Receives operating power from the host equipment—no external power supply required in typical installations.

- Revision traceability: “-51” denotes a specific build level, helping maintenance teams match revisions across their installed base.

- Professionally tested: Units are function‑checked prior to shipment to reduce on‑site trial‑and‑error and cut commissioning time.

- Service life extension: A practical way to extend legacy Rockwell platforms where system replacement is costly or time‑consuming.

- Drop‑in recovery: You might notice that swapping this board often restores faulted drives or controllers without touching field wiring.

Technical Specifications

| Brand / Model | Allen‑Bradley 81007-465-51-R |

| Part Type | Board‑level control assembly (internal spare), remanufactured (“-R”) |

| HS Code | 8538.90 (Parts suitable for use with electrical control gear) |

| Power Requirements | Powered from host backplane/internal connector; no separate supply |

| Signal I/O Types | Board‑to‑board/backplane connectors; logic‑level signaling within host unit |

| Communication Interfaces | Internal interface to the host controller/drive (no user‑facing ports) |

| Operating Temperature | Follows host equipment rating; typically within 0…55 °C when mounted in a compliant cabinet |

| Installation Method | Internal replacement board; mounts to standoffs/guides and mates to existing headers/backplane |

Application Fields

This model is typically used inside Allen‑Bradley industrial control products—such as legacy drives, controllers, or option assemblies—where a board swap restores normal operation. You’ll commonly see it in:

- Discrete manufacturing lines (packaging, material handling, assembly cells)

- Process equipment retrofits where downtime must be minimized

- Maintenance programs for mature Rockwell installations

A maintenance manager at a food‑and‑beverage plant told us a like‑for‑like board swap on a legacy panel brought a conveyor back within an hour—no PLC project edits or re‑wiring needed, which seems to be the real cost saver here.

Advantages & Value

- Reduced downtime: Direct replacement keeps production moving while you plan larger upgrades.

- Compatibility: Revision‑matched boards help avoid firmware mismatches and parameter drift.

- Budget control: Extends asset life without the immediate CAPEX of a full system changeout.

- Technical support: From part identification to revision matching and packaging advice, we assist through installation.

Installation & Maintenance

- Environment: Install inside a suitable enclosure (NEMA 12/IP54 or better, as required), with proper ventilation and clearance for airflow.

- Safety: Lockout/tagout, discharge stored energy, and follow ESD precautions (ground strap, ESD mat). Photograph cabling before removal.

- Mounting: Seat on original standoffs or card guides; check that all headers fully mate and fasteners are snug but not over‑torqued.

- Checks: After power‑up, verify status indicators on the host, load defaults if required, and confirm interlocks and I/O before returning to service.

- Upkeep: Periodically inspect connectors for oxidation, remove dust with dry air, and keep firmware of the host equipment current where applicable.

Quality & Certifications

- Manufacturing pedigree: Genuine Allen‑Bradley component; conforms to the host system’s CE/UL compliance when installed correctly.

- Quality system: Supplied from ISO 9001‑managed processes in most cases, with functional testing prior to shipment.

- RoHS/Environmental: Compliance may vary by revision and production year; we can help verify per lot if needed.

- Warranty: 365‑day warranty, with responsive support for diagnostics and replacement coordination.

If you need help confirming that 81007-465-51-R matches your installed revision, send a quick photo of your current board and the host model plate. Matching the revision label is, in many cases, the fastest way to ensure a plug‑and‑run outcome.

Reviews

There are no reviews yet.