Description

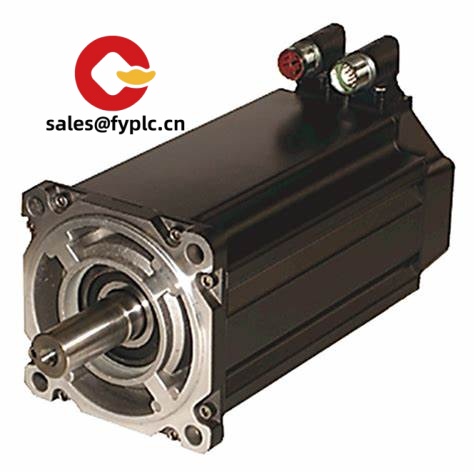

Allen‑Bradley MPL-B320P-HJ72AA – Low‑Inertia AC Servo Motor for High‑Response Kinetix Motion

The MPL‑B320P‑HJ72AA sits in Allen‑Bradley’s MP‑Series Low‑Inertia (MPL) family, the line you typically reach for when you need fast acceleration, tight speed regulation, and a compact 100 mm‑class frame. It pairs cleanly with Kinetix drives and 2090 cabling, so integrating into existing Rockwell architectures tends to be straightforward. One thing I appreciate is how the low‑inertia rotor helps machines snap to speed with less overshoot—packaging axes and pick‑and‑place heads are common beneficiaries. You might notice that the HJ72 option set indicates a factory‑fitted high‑resolution feedback and, in many cases, a 24 V dc holding brake—handy for vertical loads or e‑stops.

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express methods: FedEx, UPS, DHL

Key Features

- Low‑inertia rotor design – Enables quick start/stop and high dynamic response, especially on light‑to‑medium inertia loads.

- “P” winding (200 V‑class) – Suited for 230 V‑class Kinetix drives; sizing is typically simpler in multi‑axis machines using a common dc bus.

- HJ72 option set – Commonly configured with high‑resolution feedback and a 24 V dc brake, improving holding performance on Z‑axes.

- Compact 100 mm‑class frame – Good torque density in a small footprint; fits tight cabinets and machines where space is at a premium.

- IP‑rated housing – With the proper shaft seal and connectors installed, you typically get robust protection in dusty or oily environments.

- Rockwell ecosystem compatibility – Matched to Kinetix 350/5500/6000‑series drives and 2090 SpeedTec cabling for plug‑and‑run wiring.

- Integrated thermal sensing – Temperature feedback to the drive helps protect the motor under demanding duty cycles.

Technical Specifications

| Brand / Model | Allen‑Bradley MPL-B320P-HJ72AA (MP‑Series Low‑Inertia) |

| HS Code | 8501.52 (AC multi‑phase servo motors) |

| Power Requirements | 200 V‑class winding; powered via compatible Kinetix servo drive (typically 230 Vac class input to the drive) |

| Frame / Form Factor | 100 mm‑class MPL frame; low‑inertia rotor; medium stack length (B320 family) |

| Operating Temperature | 0…+40 °C ambient (non‑condensing), typical for MPL series |

| Signal I/O | U/V/W power phases; encoder/feedback via 2090 feedback cable; 24 V dc brake (as commonly configured with HJ72) |

| Communication Interfaces | N/A (interface through Kinetix drive power and feedback connections) |

| Installation Method | Face‑mount (IEC‑style metric flange); keyed shaft; connectorized power/feedback |

Note: Exact torque/speed values vary by winding and options. For sizing, match the motor to your Kinetix drive and duty cycle, or share the nameplate for a precise check.

Related & Supporting Products

- MPL-B310P-HJ72AA – Shorter stack, typically lower continuous torque; good where space and inertia matching favor a smaller rotor.

- MPL-B330P-HJ72AA – Longer stack variant for higher continuous torque in the same 100 mm‑class frame.

- MPL-B320K-HJ72AA – Alternate winding (K) for different base speed/voltage characteristics.

- Kinetix 350 (2097‑Vxxx), Kinetix 5500 (2198‑Hxxx), Kinetix 6000 (2093‑xxxx) – Compatible servo drives; select the axis module/drive rating based on continuous and peak current.

- 2090 Series SpeedTec Cables – Power/feedback wiring for MPL motors (e.g., 2090‑CPWM7DF‑xxAA power; 2090‑UXBN‑Sxx feedback). Lengths and bend‑radius options available.

- Accessories – Shaft seal kits for IP upgrade, mating connectors, and pre‑made cordsets for quick replacement in the field.

From my experience, a packaging OEM swapped to the B320P on a vertical axis with the brake option and saw cycle time improve by ~15% after a quick autotune on a Kinetix 5500. The low inertia made the difference on short move profiles.

Installation & Maintenance

- Mounting – Use the face‑mount flange on a flat, rigid surface; align couplings to minimize radial/axial loads. Verify shaft key engagement without forcing.

- Cabinet & Wiring – Route 2090 power and feedback cables separately (or with proper shielding) from high‑noise lines. Maintain protective earth bonding to the drive and machine frame.

- Cooling & Ventilation – Provide free air around the motor body; avoid enclosing the motor without forced ventilation, as it may derate in warm areas.

- Brake & Feedback – If equipped with a holding brake, supply a clean 24 V dc source. Handle encoder connectors carefully; contamination on pins can cause intermittent faults.

- Drive Setup – Import motor catalog data in Studio 5000/drive tools, run the tuning routine, and verify peak current limits to protect the mechanics.

- Routine Care – Periodically check connector tightness, cable strain relief, and shaft seal condition. Light exterior cleaning is fine; avoid solvents on nameplates or seals.

- Firmware & Logs – Keep your Kinetix drive firmware current and review fault logs; it seems to prevent most nuisance trips in many cases.

Quality & Certifications

- CE and cULus marking for industrial machinery, typical for MPL series

- RoHS compliance for restricted substances

- Manufacturer’s warranty is typically 12 months; our supply warranty is 365 days as stated above

Reviews

There are no reviews yet.