Description

Allen‑Bradley 1336F-MCB-SP2G – Main Control Board (MCB) for 1336 FORCE AC Drives

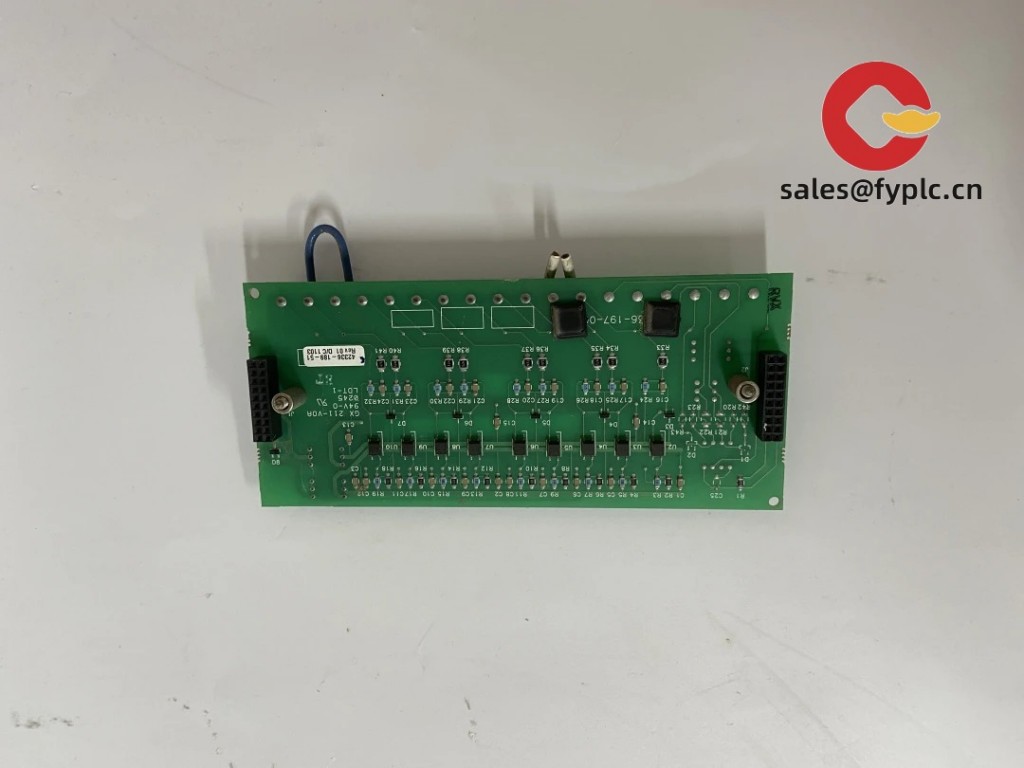

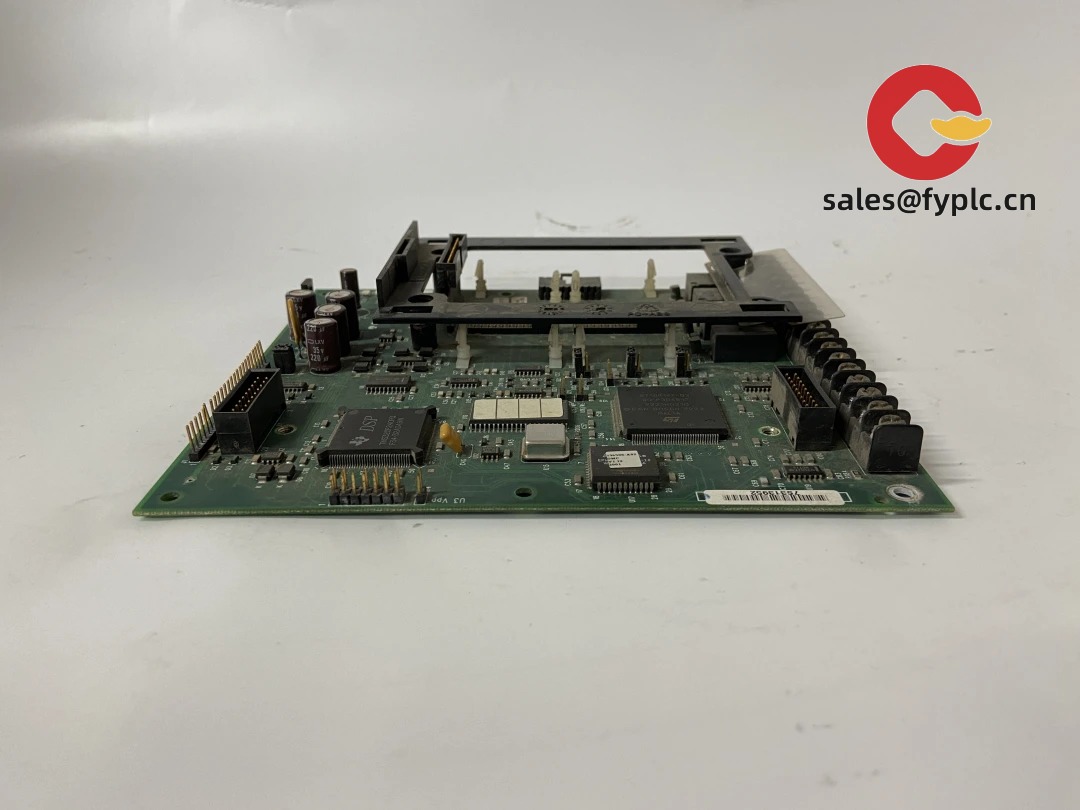

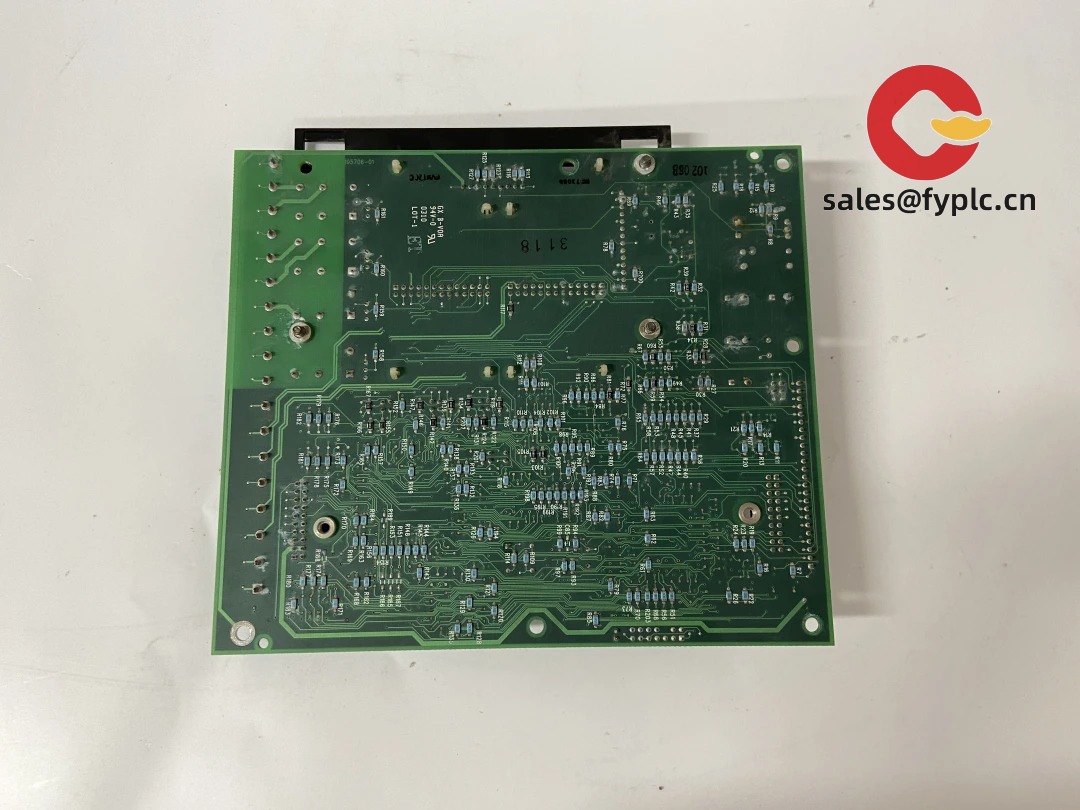

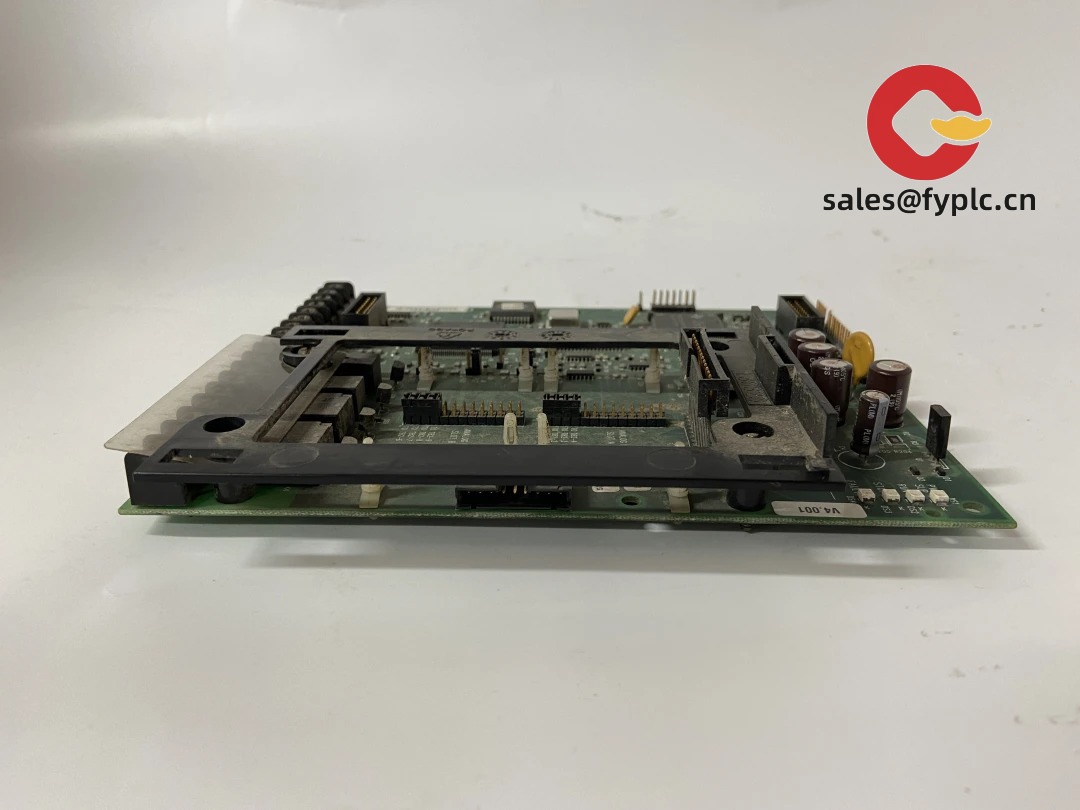

The Allen‑Bradley 1336F-MCB-SP2G is a Main Control Board used inside 1336 FORCE series variable‑frequency drives. From my experience, this is the board maintenance teams reach for when a drive powers up but won’t run, loses its I/O logic, or shows persistent control faults. Swap the MCB, reseat the ribbon cables, and—if the power section is healthy—the drive typically comes back with minimal rework. You might notice the robust connector set and test points; those details make a quick, confident changeout much easier during a short outage.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and connector integrity check; ESD‑safe, shock‑resistant packing

Key Features

- Like‑for‑like control core – Restores the logic/control section of 1336 FORCE drives without changing cabinet wiring or parameters (when backups are available).

- Fast swap mechanics – Standoff mounts and keyed ribbon connectors keep the change predictable; typically a single‑window maintenance job.

- I/O and feedback handling – Interfaces power stage gating, drive I/O, keypad/HIM, and speed/torque feedback (tach/encoder) depending on drive build.

- Noise‑tolerant design – Built for electrically harsh VFD enclosures running 24/7.

- Data retention support – Works with the drive’s parameter storage; cloning via HIM or software typically shortens commissioning.

Technical Specifications

| Brand / Model | Allen‑Bradley 1336F-MCB-SP2G |

| Product Type | Main Control Board (MCB) for 1336 FORCE AC drives |

| Compatible Family | A‑B 1336F (FORCE) VFDs; compatibility is variant‑dependent—confirm by drive catalog/series |

| HS Code (reference) | 8504.90 – Parts of static converters (final classification may vary by country) |

| Power Requirements | Supplied by drive low‑voltage rails (e.g., +5 VDC and ±15 VDC from the drive’s internal PSU) |

| Signal I/O Types | Ribbon/board headers for gating control, analog refs/feedback, digital I/O, keypad/HIM; exact mix by drive option set |

| Communication Interfaces | Internal to drive; external comms (e.g., DPI/fieldbus) handled by option cards/HIM, not the bare MCB |

| Dimensions & Weight (approx.) | PCB class ~300 × 180 mm; ~0.35–0.6 kg |

| Operating Temperature | Drive‑enclosure environment, typically 0…+50 °C; non‑condensing |

| Installation Method | Internal board replacement; mount on standoffs, engage keyed ribbons, verify ground bonding and connector seating |

Application Fields

A straightforward way to recover 1336 FORCE drives in:

- Metals and converting lines – fast return to service after a logic‑side fault.

- Pulp & paper – restoring section drives where downtime costs build quickly.

- Water & wastewater – blowers/pumps where spare drives are scarce.

- Material handling and packaging – conveyors and winders that run nonstop.

One maintenance tech told me, “We swapped the MCB, cloned parameters from the HIM, and the 1336F was back on speed before lunch.” That’s been the pattern in many cases when the power section and fans are healthy.

Advantages & Value

- Reliability – Factory‑spec control hardware for stable speed/torque control.

- Compatibility – Designed for the 1336F family; preserves cabinet wiring and accessory ecosystem.

- Cost savings – A board‑level repair often avoids a full drive replacement and re‑engineering.

- Support – We can help confirm revision/firmware alignment and cloning steps to shorten downtime.

- Clear logistics – Practical lead times and pre‑shipment checks fit outage windows.

Installation & Maintenance

- Safety & ESD: Lock out incoming power; wait for DC bus to discharge; handle board with a grounded wrist strap.

- Board swap: Photograph cable routing; move one connector at a time; verify all standoffs and grounds are tight.

- Parameter handling: Use the HIM/tool to back up and restore parameters; confirm motor data and scaling.

- EMC & wiring: Keep signal ribbons clear of high‑current paths; secure harnesses to avoid vibration wear.

- Post‑start checks: Monitor current, thermal status, and fault logs; confirm fan operation and enclosure airflow.

- Routine care: Quarterly dust cleaning and connector re‑torque; trend heatsink temps and fault history.

Quality & Certifications

- Built to Rockwell Automation quality standards (ISO 9001 aligned manufacturing).

- System compliance (CE/UL) is maintained at the drive level; this is a drive spare component.

- RoHS status depends on production lot; we can confirm by part/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.