Description

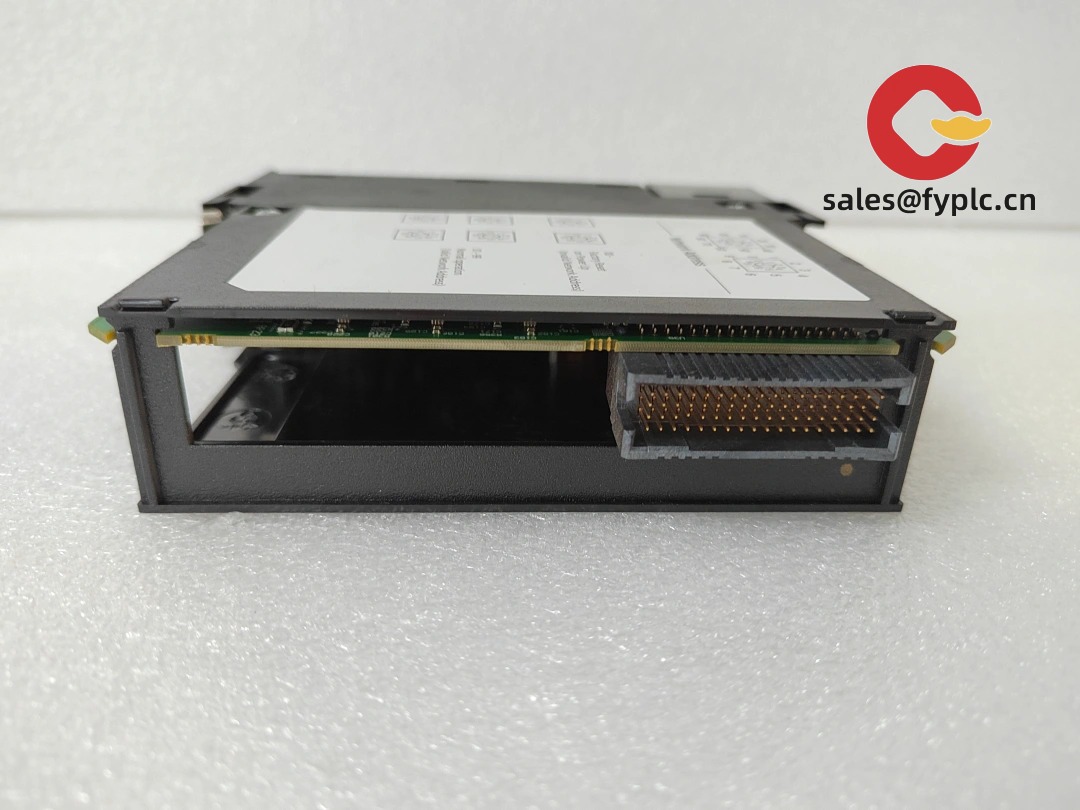

Allen‑Bradley 1756‑CN2R_B – ControlLogix ControlNet Module with Redundant Media (Series B)

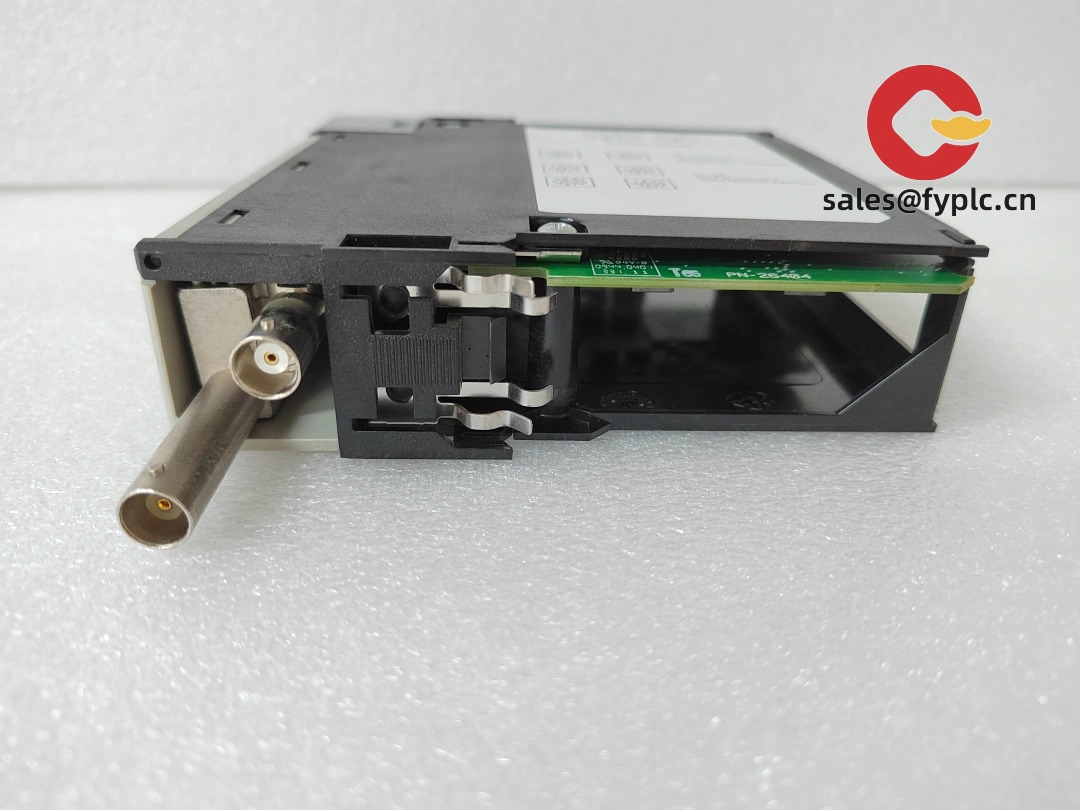

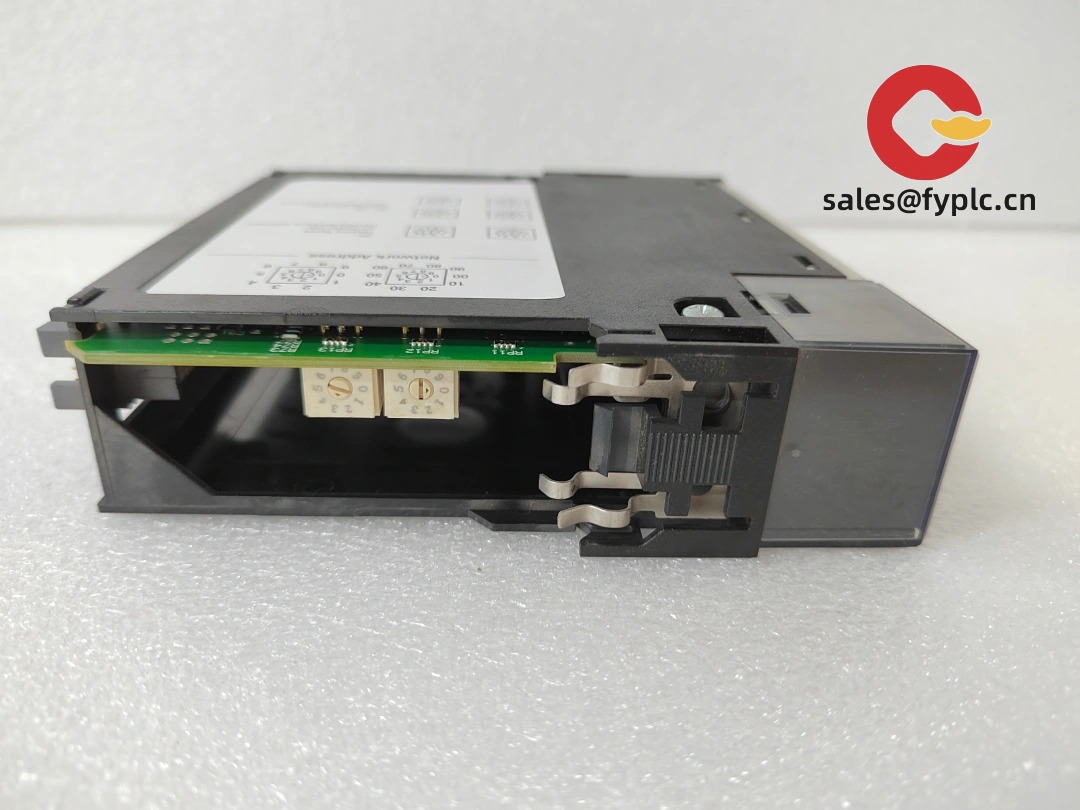

The 1756‑CN2R_B is a ControlNet communication module for ControlLogix that supports redundant media (Channel A/B) on coax. From my experience, teams choose this Series B version when they need deterministic, scheduled ControlNet for remote I/O or peer control—and want the extra resilience of dual-media paths. You might notice the front BNC connectors and the rotary node switches; that combination typically makes addressing and commissioning pretty predictable during a short outage.

Company’s Order Placement Process and Guarantees

- The warranty period is 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification and port integrity; ESD‑safe, shock‑resistant packing

Key Features

- Redundant ControlNet media – Dual BNC (Channel A/B) for higher availability on 75 Ω RG‑6 coax runs.

- Deterministic scheduled updates – Supports ControlNet’s scheduled/unscheduled traffic for time‑critical I/O and coordination.

- Simple addressing – Rotary node switches on the front simplify swaps and keep addressing consistent.

- Backplane bridge – Routes data between ControlNet and the 1756 backplane for controllers, remote I/O, or peer modules.

- Proven in 24/7 duty – Series B mechanics and status LEDs make diagnostics straightforward in the field.

- 5 Mbit/s speed – Standard ControlNet throughput for predictable, time‑sliced transfers.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756‑CN2R_B (ControlLogix, Series B) |

| Function | ControlNet communication module with redundant media (A/B) for ControlLogix racks |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment |

| Power Requirements | Powered via 1756 backplane (no separate external power input on the module) |

| Communication Interfaces | ControlNet coax, BNC connectors for Channel A and Channel B; 5 Mbit/s |

| Signal I/O Types | Scheduled/unscheduled ControlNet data; backplane interface to controller and I/O modules |

| Cabling | 75 Ω RG‑6 quad‑shield coax with approved ControlNet taps/terminators (redundant media capable) |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | Standard 1756 single‑slot module; ~0.3–0.5 kg |

| Installation Method | Plug into 1756 chassis slot; set node address via rotary switches; wire ControlNet A/B with proper taps/terminators |

Application Fields

I tend to see the 1756‑CN2R_B in plants that want deterministic, high‑uptime ControlNet segments:

- Remote I/O for process skids and MCCs where scheduled updates matter.

- Peer‑to‑peer ControlLogix coordination on redundant A/B media.

- Drive and motion islands that still rely on ControlNet determinism.

- Brownfield expansions where ControlNet is standard and uptime is critical.

A maintenance lead told me, “We set the node on the rotaries, landed both A and B, and the scheduled connections went green on the first scan.” That’s been typical when taps and terminations are tidy.

Advantages & Value

- Reliability – Redundant media and clear status LEDs reduce nuisance downtime.

- Compatibility – Native to ControlLogix; works with established ControlNet infrastructure and devices.

- Cost control – Drop‑in replacement that preserves existing topology and cabinet wiring.

- Maintainability – Rotary addressing and predictable diagnostics shorten outage windows.

- Support – We can help confirm node plans, tap types, and basic scheduling checks before your window.

Installation & Maintenance

- Cabling & topology: Use approved 75 Ω RG‑6 quad‑shield coax, ControlNet taps, and terminators; keep stubs short; maintain both A and B paths if using redundancy.

- Addressing: Set node with front rotary switches; document node IDs on the panel door for quick reference.

- Grounding/EMC: Bond shields per Rockwell guidance; route coax away from VFD motor leads to reduce noise.

- Scheduling: Validate the network schedule in RSNetWorx for ControlNet (or equivalent); check connection status bits after download.

- Routine care: Periodic visual inspection, re‑torque of BNC/tap connections, and a quick review of link health and error counters.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE/UL/cUL markings apply at the system/module level per Rockwell documentation.

- RoHS status depends on series/lot; we can confirm by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.