Description

ALSTOM 42011-106-00 A01 ITC_VIOM_VIOC VER.A01 – I/O Controller Module for Industrial Control Racks

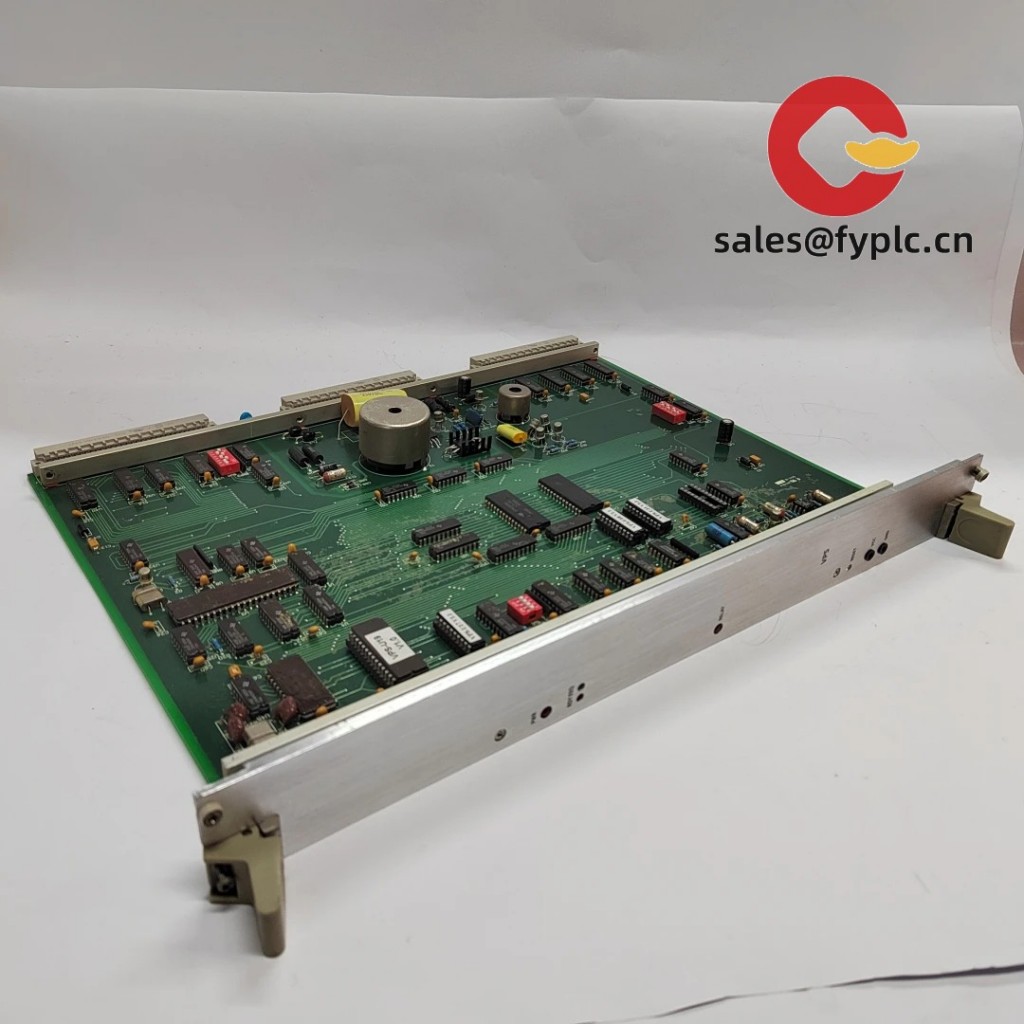

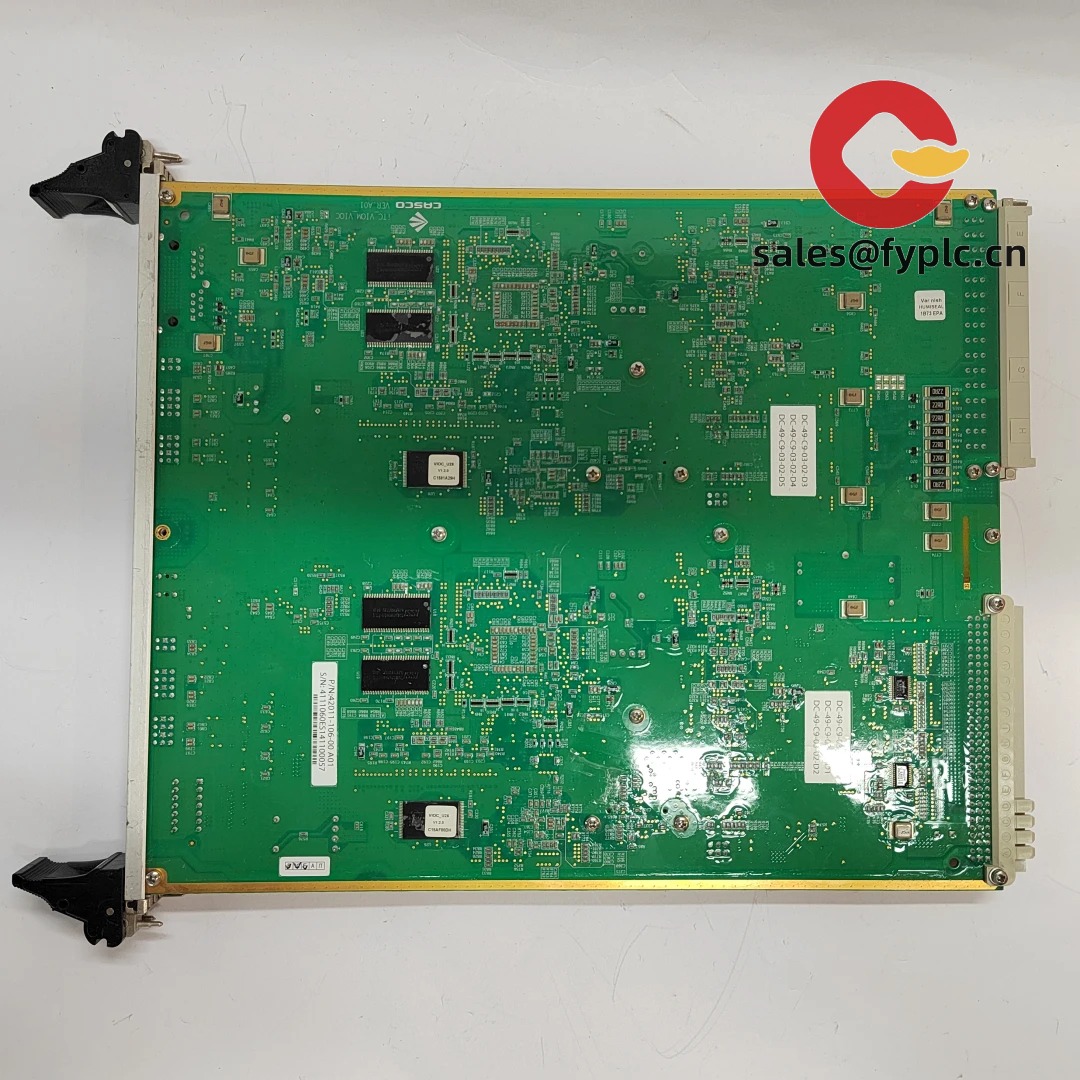

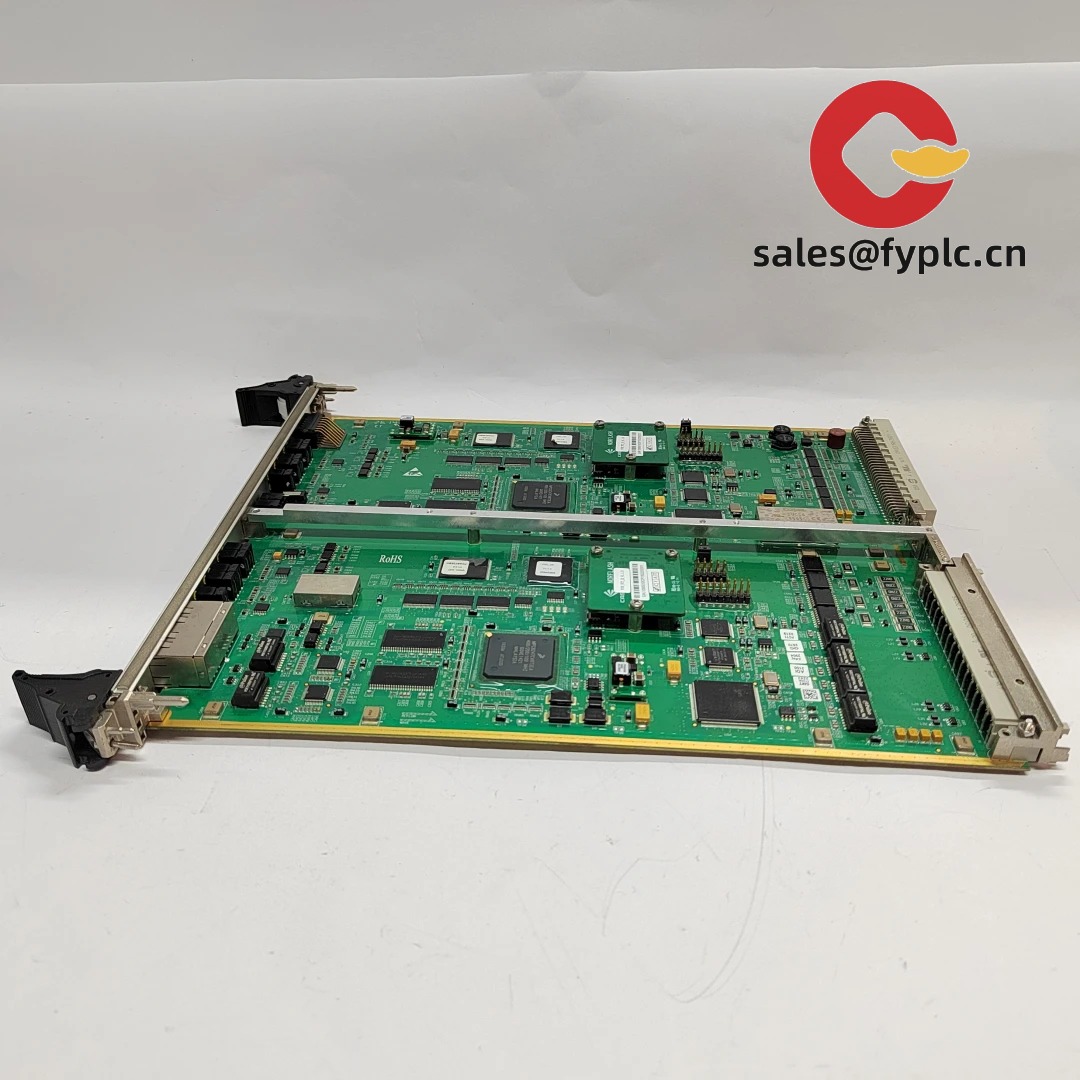

The ALSTOM 42011-106-00 A01 (ITC_VIOM_VIOC, VER.A01) is a rack-mounted I/O controller card used in ALSTOM ITC systems, typically paired with VIOM/VIOC backplanes and field termination boards. From my experience, this board serves as the bridge between the system processor and your field signals—coordinating discrete I/O and, in many cases, analog channels through companion interface modules. If you are maintaining legacy ALSTOM installations in power generation or heavy industry, this module is a practical, drop-in path to extend system life with minimal re-engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock items; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- ITC/VIOM/VIOC rack compatibility: Designed to operate within ALSTOM ITC frames using VIOM/VIOC backplanes for field I/O routing.

- Deterministic backplane communication: Stable real-time I/O scanning via the system bus, which typically means predictable response in closed-loop control.

- Industrial cabinet temperature range: In many cases specified for 0–55°C cabinet environments, suitable for power plants and process lines.

- Diagnostic indication: Front-panel LEDs usually provide quick health and status checks without opening the cabinet.

- Discrete and analog signal support: Discrete 24 VDC I/O is common; analog (4–20 mA or 0–10 V) is handled via companion I/O interface cards.

- Serviceability: Rack slide-in/out design simplifies replacement during planned outages and helps reduce downtime.

- Revision A01: Verified build level for sites matching VER.A01 across installed bases; helps ensure behavior consistency across redundant racks.

Technical Specifications

| Brand / Model | ALSTOM 42011-106-00 A01 ITC_VIOM_VIOC VER.A01 |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | Backplane-supplied logic power (commonly 5 VDC); field side typically 24 VDC via I/O interface cards |

| Dimensions & Weight | Approx. 6U Eurocard (about 233 × 160 mm); typically 0.6–0.8 kg depending on front hardware |

| Operating Temperature | 0 to +55 °C (typical control cabinet rating) |

| Signal Input/Output Types | Discrete 24 VDC DI/DO; optional analog 4–20 mA / 0–10 V via related VIOM/VIOC I/O cards |

| Communication Interfaces | System backplane bus (ITC/VIOM/VIOC); front terminal/connectors; some revisions include a service serial header |

| Installation Method | Rack-mounted card, slides into backplane; front-panel fastening screws for retention |

| Revision | A01 (VER.A01) |

Application Fields

- Gas/steam turbine control, balance-of-plant sequencing, and auxiliary systems

- Power generation substations and switching yards needing deterministic I/O handling

- Process industries (cement, metals, chemicals) with legacy ALSTOM ITC racks

- Rail and traction substations where VIOM/VIOC-based controls are still in service

Advantages & Value

- Drop-in compatibility: Keeps your existing ITC/VIOM/VIOC architecture intact—no rewiring or new software in most cases.

- Risk reduction: Proven hardware behavior helps stabilize scan times and reduce nuisance trips after replacement.

- Lifecycle extension: Ideal for fleets standardizing on ALSTOM ITC; defers costly platform migrations.

- Procurement efficiency: Fast lead times and a 365-day warranty simplify outage planning and spares strategy.

- Technical support: We can assist with part identification, revision matching, and compatible accessories (backplanes, VIOM terminal boards, harnesses).

A maintenance supervisor at a combined-cycle plant told us, “After swapping the VIOC controller card for the 42011-106-00 A01, the I/O scans settled immediately and we cleared several intermittent faults we’d been chasing for months.” That seems to be a common theme with well-matched revisions.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated 19-inch cabinet or OEM rack; maintain ambient within 0–55°C and avoid condensation.

- ESD handling: Use proper grounding and ESD protection when inserting/removing the card; power down the rack unless your site procedures specify otherwise.

- Backplane insertion: Align the card with the guides, seat firmly into the connector, then secure with the front-panel screws to the recommended torque.

- Wiring: Field wiring connects to VIOM/VIOC terminal boards; keep 24 VDC field loops and analog signals separated from noisy loads, and ensure shield terminations are consistent.

- Power checks: Verify backplane 5 VDC (logic) and any 24 VDC field supply are within tolerance before commissioning.

- Routine care: Quarterly visual checks for connector oxidation and dust; clean with dry, oil-free air. Firmware or configuration changes should be performed by qualified personnel and documented.

- Spares strategy: For critical services, keep at least one matched-revision spare; label with rack slot and configuration notes.

Quality & Certifications

- Manufacturer standards: ALSTOM hardware is typically produced under ISO 9001 quality systems.

- Compliance: CE marking is common for cabinet-installed control modules; UL recognition and RoHS status may vary by production year—please share your serial/revision for confirmation.

- Warranty: 365-day warranty coverage from us, with exchange/repair options if needed.

Related/Supporting Components

- VIOM/VIOC backplane and rack hardware compatible with ITC systems

- Field termination boards for discrete and analog signals (24 VDC, 4–20 mA, 0–10 V)

- Shielded ribbon or harness sets for rack-to-terminal board connections

- Redundant controller slots and power supplies where the application requires high availability

Reviews

There are no reviews yet.