Description

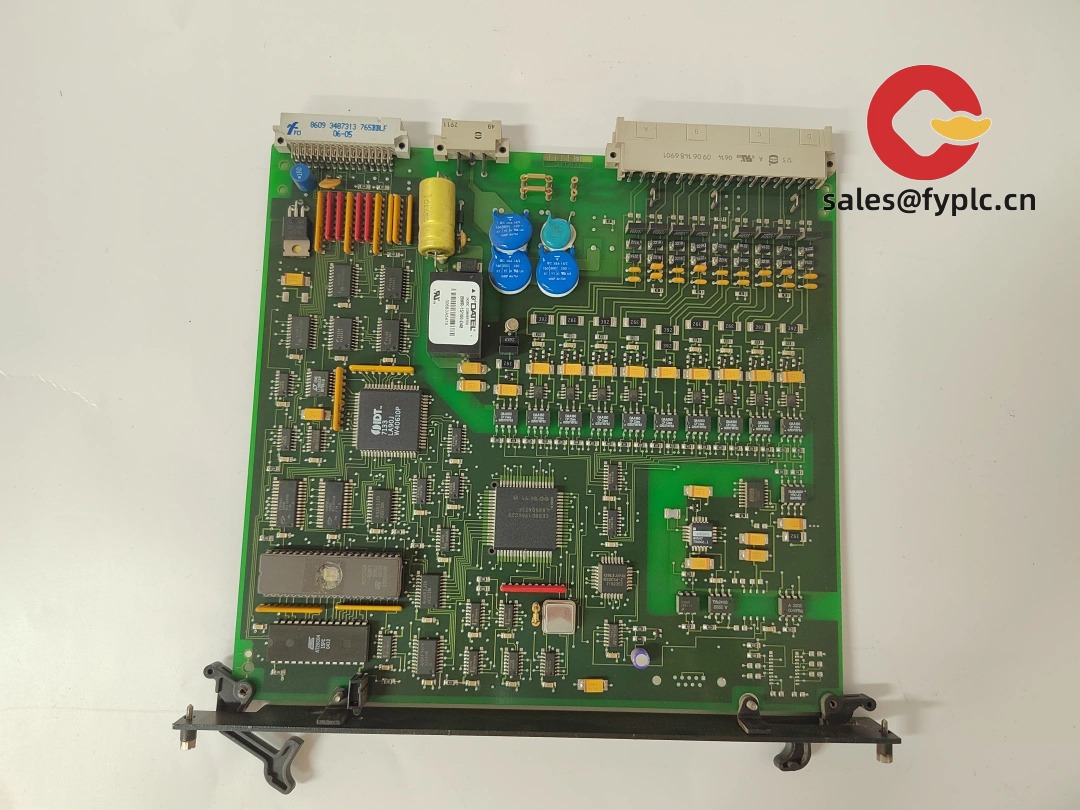

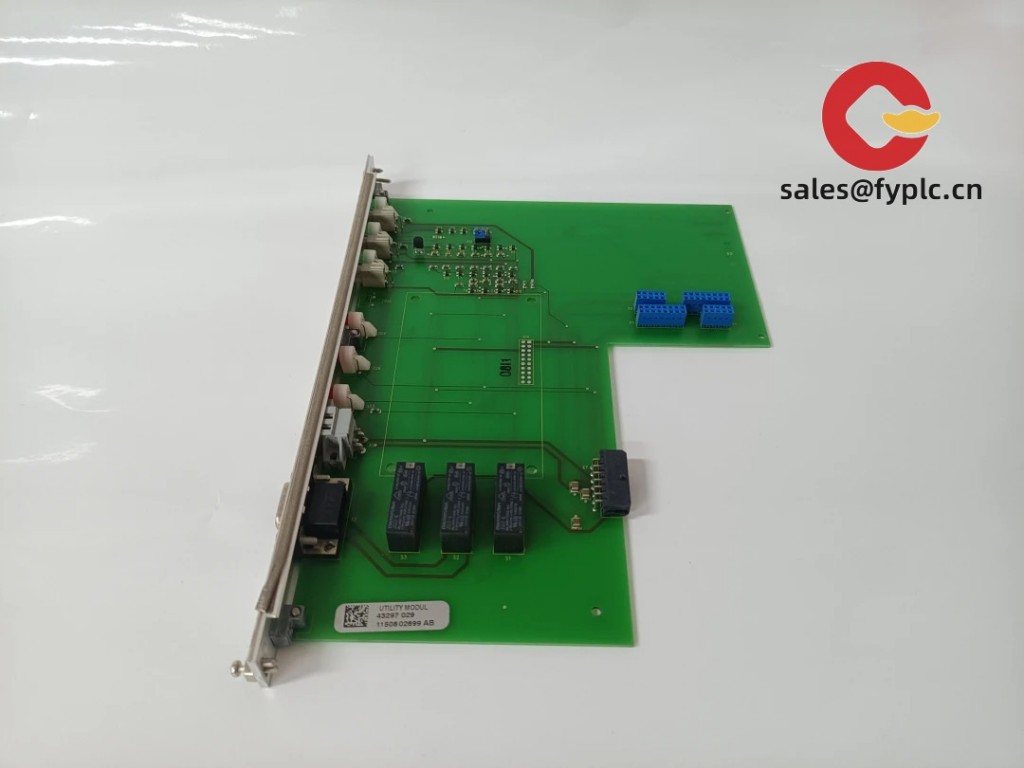

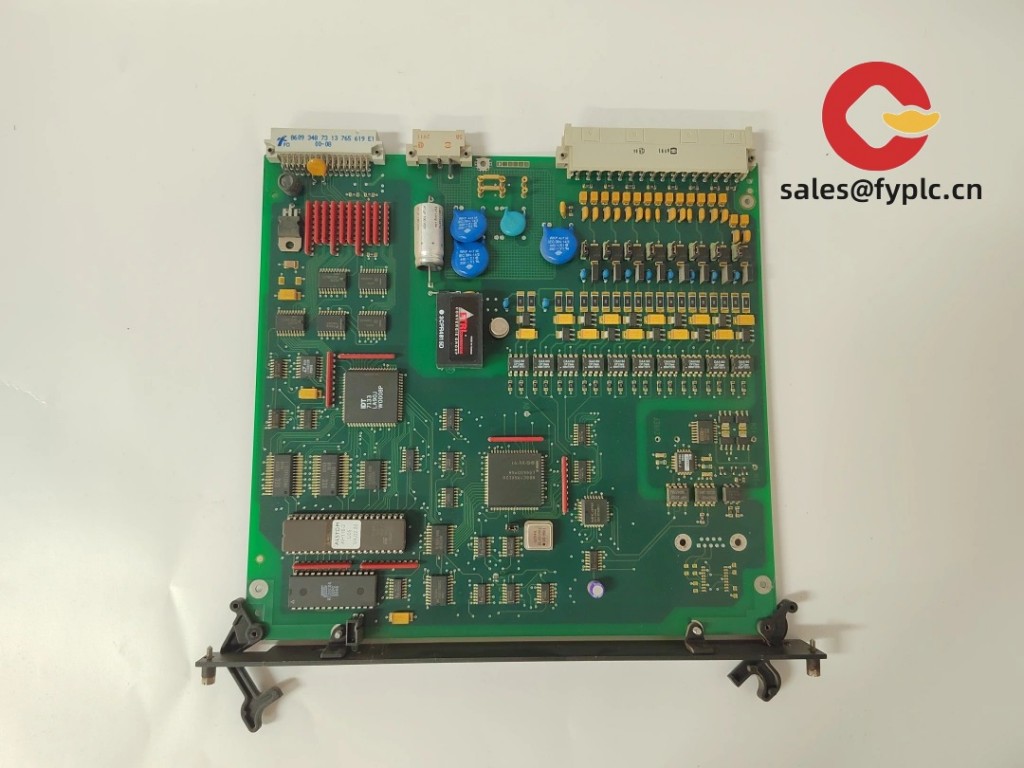

ALSTOM AB121 – Modular Control Board for Legacy Signaling and Automation Racks

The ALSTOM AB121 is a plug-in control module used widely across legacy ALSTOM rack systems in signaling, traction power, and plant automation. From my experience, customers typically look for the AB121 as a direct, drop-in replacement to keep existing cabinets running without redesigning the whole panel. It’s the kind of board you fit once, verify status LEDs, and you’re back online fast—minimal disruption, no surprises.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how predictable this flow is—teams can plan outages and slot-in replacements with confidence. If you need test reports or photos before shipment, we can typically provide those as well.

Key Features

- Drop-in compatibility – Designed for ALSTOM rack/backplane systems, so retrofit work is usually minimal.

- Backplane-powered architecture – Power and I/O handled through the system backplane; wiring remains tidy and serviceable.

- Status indication – You might notice front-facing LEDs on many AB-series units, helping technicians check health at a glance.

- Stable operation in harsh cabinets – Built for 24/7 service in signaling rooms, traction substations, and process plants.

- Lifecycle continuity – Ideal for installed-base maintenance where re-engineering is not practical or too costly.

- Traceable supply – From my experience, matching firmware/hardware revisions keeps commissioning time short and predictable.

Technical Specifications

Exact values can vary by revision/build code. The data below reflects what is typically encountered for AB-series plug-in modules used in ALSTOM cabinets.

| Brand / Model | ALSTOM / AB121 |

|---|---|

| HS Code (reference) | 8537.10 – Boards, panels, consoles, etc., for electric control or distribution (final classification may vary by configuration and local customs). |

| Power Requirements | Backplane-supplied (typical system buses 24 VDC or 48 VDC; refer to host rack PSU rating). |

| Operating Temperature | Commonly -10°C to +55°C when installed in the specified ALSTOM rack and enclosure. |

| Signal I/O Types | Discrete and/or analog channels via backplane; function depends on AB121 variant and system role. |

| Communication Interfaces | Module communicates through the system backplane; external interfaces are provided by the host controller (often serial or Ethernet at the system level). |

| Installation Method | Plug-in rack module; front-inserted with locking fasteners; ESD-safe handling required. |

| Dimensions & Weight | Standard ALSTOM plug-in card format; fits the designated rack slot; typical module weight under 0.6 kg. |

Application Fields

- Railway signaling rooms and interlocking cabinets

- Traction power substations and depot automation

- Plant utilities and process skids built around ALSTOM control racks

- Refurbishment projects where existing wiring and backplanes are retained

A maintenance supervisor at a traction substation told us the AB121 swap “took under an hour end-to-end—no rewiring, no reprogramming, just a straight module replacement.” That’s usually what teams want when uptime matters.

Advantages & Value

- Reliability – Intended for continuous service in cabinets that run year-round.

- Compatibility – Works with established ALSTOM backplanes; reduces integration risk and testing overhead.

- Cost Control – Avoids panel redesign and new approvals; spare-based strategy typically saves both time and engineering cost.

- Traceable Supply & Support – We help match revisions and firmware to what you already run, which seems to be the quickest way to a clean FAT/SAT.

Installation & Maintenance

- Install in the specified ALSTOM rack slot; confirm backplane connector alignment before fastening.

- Power down and discharge as per site LOTO procedure; use ESD protection when handling the module.

- Ensure cabinet ventilation meets manufacturer recommendations; avoid dust buildup around card guides and connectors.

- Wiring remains on the host rack/terminal assemblies; verify system grounding and shielding continuity.

- Routine checks: visual inspection each maintenance cycle, clean dust with dry air, and log any firmware/hardware revision changes.

Quality & Certifications

- Manufacturer quality programs typically aligned with ISO 9001

- CE marking is common for EU deployments; UL/CSA markings may vary by market and revision

- RoHS applicability depends on production year and variant; documentation available on request

- Warranty: 365 days

Supporting Components (often paired)

- ALSTOM system backplane/rack and rack power supplies (e.g., 24 VDC / 48 VDC PSU modules)

- Terminal assemblies and interposing relays used within existing cabinets

- Host controllers/CPUs that manage communications over the backplane

If you share your current rack type, PSU voltage, and the AB121 revision code on site, we can cross-check compatibility before you place the order—this typically avoids avoidable downtime.

Reviews

There are no reviews yet.