Description

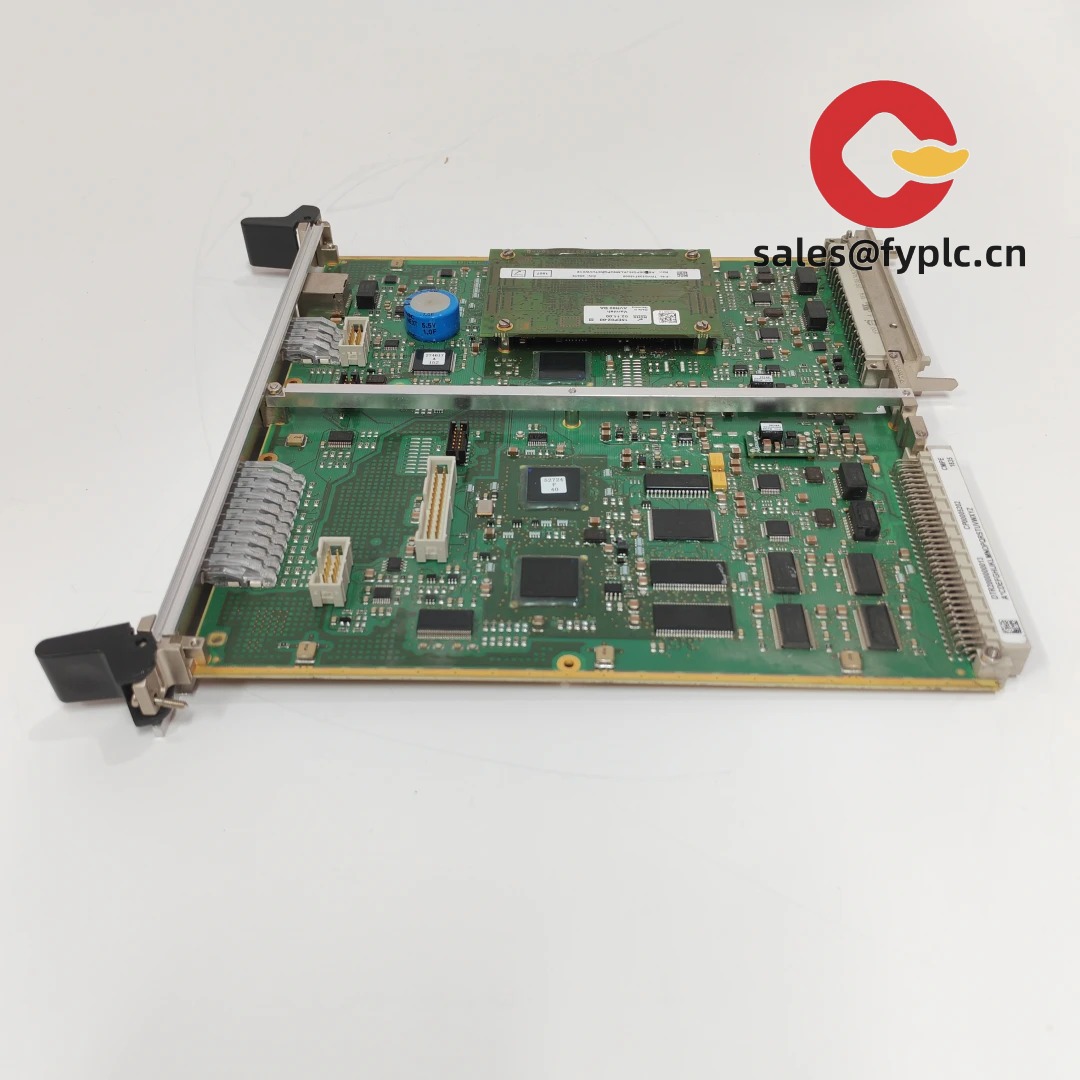

ALSTOM CMP1838 (TRVCO62345000 / CP00005202) – Plug‑in Control Module for Legacy ALSTOM Racks

The ALSTOM CMP1838, marked with internal references TRVCO62345000 and CP00005202, is a plug‑in control/processor board designed for ALSTOM rack-based control systems. From my experience, this board is typically used as a replacement part to restore a downed control cabinet in traction power, power generation, or industrial process control. You might notice that the CMP1838 slots straight into the existing backplane, which keeps field wiring untouched and gets production back online faster.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Direct rack integration: Plug‑in module designed for ALSTOM backplanes, so swap-out is quick and clean.

- Backplane-powered: Draws power from the host rack (typically a 24 VDC system), avoiding extra field supplies.

- Backplane I/O exchange: Signals and data are exchanged via the system bus; field wiring stays on the I/O cards.

- Service-friendly design: Front extraction handles and guided rails (in most cases) help reduce handling damage.

- Lifecycle support: Ideal for legacy installations where a like‑for‑like replacement minimizes engineering changes.

- Stable operation: Built for enclosed control cabinets; appears to be optimized for continuous service.

- Traceable identifiers: TRVCO62345000 and CP00005202 references aid maintenance teams in part matching.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | ALSTOM CMP1838 (references: TRVCO62345000, CP00005202) |

| Product Type | Rack plug‑in control/processor module for ALSTOM systems |

| HS Code | 8538.90 (Parts suitable for use with apparatus of heading 8537) |

| Power Requirements | Supplied via system backplane; typically from a 24 VDC rack supply |

| Signal I/O Types | Data and control via proprietary backplane; field I/O handled by companion cards |

| Communication Interfaces | Backplane bus interface to host rack (no separate field ports on the module in typical setups) |

| Installation Method | Plug‑in to ALSTOM rack backplane; front retention/locking levers typical |

| Operating Environment | Enclosed control cabinet, dry/clean air, vibration-damped mounting preferred |

Application Fields

The CMP1838 is commonly found in ALSTOM rack-based systems used across:

- Rail traction/converter control cabinets where rapid board swaps keep rolling stock or traction substations operational.

- Power generation control rooms (steam/gas balance-of-plant) where tight turnaround on spares reduces outage risk.

- Substation automation and protection frameworks using ALSTOM legacy racks.

- Industrial process controls that rely on ALSTOM cabinet architectures for supervisory logic and interlocks.

A maintenance lead recently mentioned that replacing the CMP1838 “brought the interlock logic back within one maintenance window,” which, in many cases, saves a full day of production time.

Advantages & Value

- Risk-free replacement: Like‑for‑like module reduces requalification and avoids rewiring.

- Short downtime: Board swap is typically faster than re-engineering or retrofitting alternative platforms.

- Compatibility: Works within the original ALSTOM backplane and power ecosystem.

- Cost control: Extends system life without a full upgrade project or new software validation cycles.

- Technical support: We can assist with part identification, pre‑shipment testing options, and packing for long-distance transport.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated rack; maintain ambient within typical control-cabinet ranges.

- ESD handling: Use wrist straps and antistatic packaging; avoid touching component leads.

- Seating and locking: Align with the guide rails, apply even pressure to seat the edge connector, then engage the front locks.

- Wiring: No field wiring to the module; verify backplane connector condition and mating pins.

- Routine checks: Periodic dust removal with dry, oil‑free air; inspect connectors for oxidation; verify rack supply voltage stability.

- Firmware/config: If the system requires a configuration load, follow the site’s established commissioning procedure and change control.

Quality & Certifications

- Typically integrated in systems that comply with CE requirements; component-level marking may vary by revision.

- Manufacturing and supply processes aligned with ISO 9001 quality practices in most cases.

- RoHS status depends on production date and revision; legacy parts can be exempt when used as service spares.

- 365-day warranty coverage as stated above.

Recommended Companion Components

- ALSTOM rack backplane: Hosts the CMP1838 and routes power/bus signals; verify slot and revision compatibility.

- Rack power supply module (24 VDC): Provides stable DC bus voltage; many sites keep one spare to protect uptime.

- Digital/analog I/O cards: Field wiring remains on these modules; ensure firmware/config aligns with the CMP1838 requirements.

- Front panel hardware: Retention levers and faceplate screws for secure mounting, especially in vibration-prone environments.

If you’d like, share your installed rack code or a photo of the slot label; in many cases that’s enough to confirm compatibility with the CMP1838 marked TRVCO62345000 / CP00005202.

Reviews

There are no reviews yet.