Description

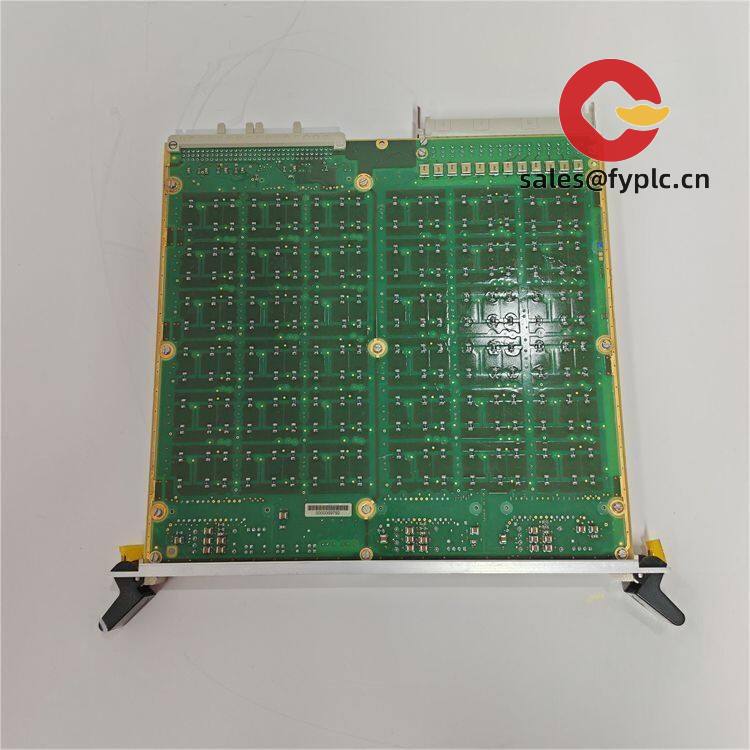

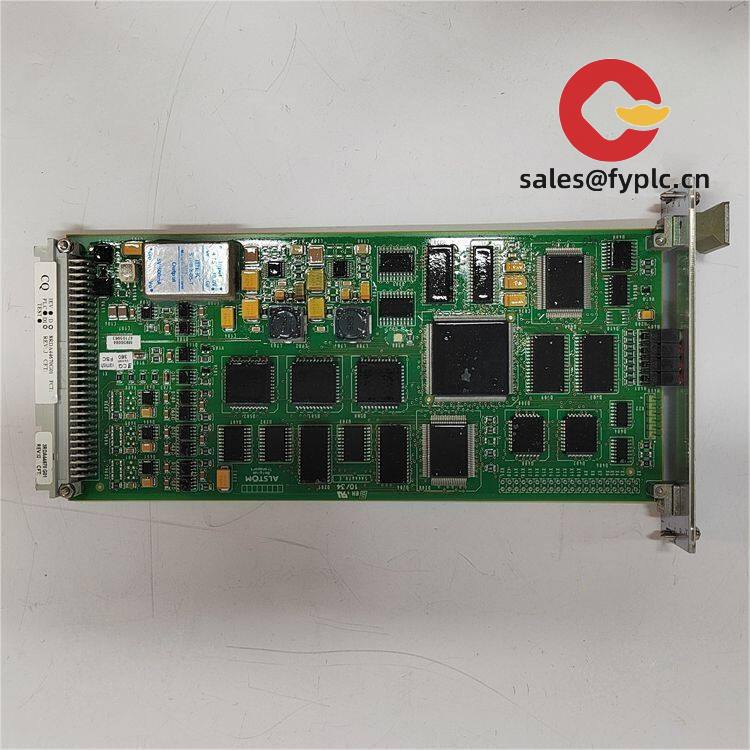

ALSTOM CMP1838‑TRVCO62345000‑CP00005202 – Plug‑in Railway Control/Signaling Interface Module

This ALSTOM module, CMP1838‑TRVCO62345000‑CP00005202, is a plug‑in PCB assembly typically used in rolling stock or trackside control cabinets. From my experience, it’s applied as a control/signal interface board within TCMS and signaling subsystems, where stable 24 VDC power, reliable backplane connectivity, and robust EMC behavior really matter.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Railway‑grade design – Built for stable operation in cabinets subject to vibration and electrical noise, which you’ll typically see on rolling stock.

- 24 VDC power domain – Suited for common railway control power buses, easing integration in existing racks.

- Backplane I/O connectivity – Interfaces via the rack connector; you might notice it reduces front‑panel wiring and speeds swap‑outs.

- Multi‑signal handling – Usually supports a mix of digital I/O and conditioned analog signals used for control, status, and interlock channels.

- Service-friendly – Plug‑in form factor enables quick replacement; in many cases, no field recalibration is required after swap if the rack is healthy.

Technical Specifications

| Brand / Model | ALSTOM CMP1838‑TRVCO62345000‑CP00005202 |

| HS Code | 853890 (Parts suitable for electrical control/switchgear) |

| Power Requirements | 24 VDC nominal (typically 18–36 VDC), <15 W typical |

| Dimensions & Weight | Approx. 160 × 100 mm PCB (3U Eurocard style), ~0.30 kg |

| Operating Temperature | Typically −25°C to +70°C (railway cabinet environment) |

| Signal I/O Types | Mixed digital I/O via backplane; conditioned analog channels (e.g., 0–10 V / 4–20 mA) depending on revision |

| Communication Interfaces | Commonly RS‑485/RS‑422; CAN or 10/100 Ethernet may be present for service/diagnostics (variant‑dependent) |

| Installation Method | Plug‑in module for ALSTOM rack/backplane; secured via front panel; used inside ventilated control cabinet |

Note: Specific I/O mix and ports can vary by board revision; we can help verify against your trainset or interlocking BOM.

Application Fields

- Rolling stock TCMS subsystems (status monitoring, discrete control, interlocks)

- Traction and auxiliary systems interface within equipment racks

- Wayside/trackside cabinets handling signaling I/O and diagnostics

- Depot test benches and maintenance simulators for ALSTOM control racks

Advantages & Value

- Form‑fit compatibility – Designed to work in existing ALSTOM backplanes, which typically keeps retrofit labor low.

- Reliability in harsh environments – Stable behavior under vibration and EMC exposure common in rail applications.

- Lifecycle support – We assist with revision matching and traceability, reducing costly rework during fleet maintenance.

- Pre‑shipment checks – Functional inspection and packaging to reduce DOA risk and shorten time‑to‑service.

“We swapped the CMP1838‑TRVCO board during a scheduled A‑check, and the rack came up clean on the first cycle. No extra wiring, no surprises.” — Maintenance supervisor at a metropolitan rail depot

Installation & Maintenance

- Cabinet environment – Install in a ventilated control cabinet; avoid condensation; keep ambient within the specified temperature range.

- Power & grounding – Use a clean 24 VDC supply with proper grounding; from my experience, poor earthing is the top cause of intermittent faults.

- Backplane handling – De‑energize the rack before insertion/removal; align carefully to protect the edge connector; observe ESD precautions.

- Wiring – Route I/O and communication pairs away from high‑current lines; twisting RS‑485/422 pairs typically reduces noise pickup.

- Routine maintenance – Annual dust cleaning with dry air; review event logs; update firmware only if the exact revision is approved for your fleet.

- Spare policy – Keep at least one board per active rack type; verify part/revision codes against your BOM before dispatch.

Quality & Certifications

- CE and RoHS compliance for electronic assemblies

- Manufactured under ISO 9001 quality systems

- Railway standards typically targeted by this class of modules: EN 50155 (rolling stock electronics), EN 50121‑3‑2 (EMC)

- Warranty: 365 days from shipment

Certification scope can vary by revision and production lot. If you share the exact serial/revision, we’ll confirm the test reports available for your documentation set.

Reviews

There are no reviews yet.