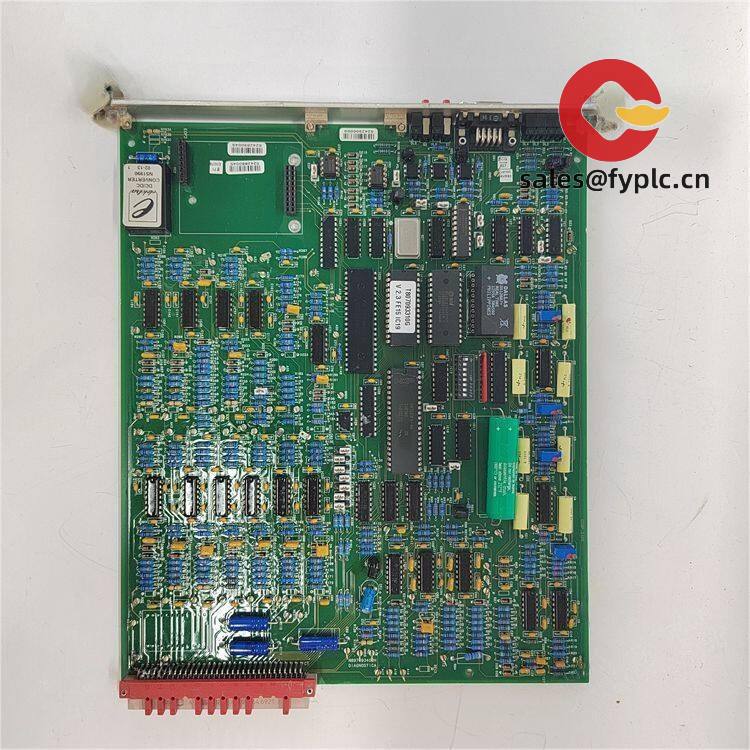

Description

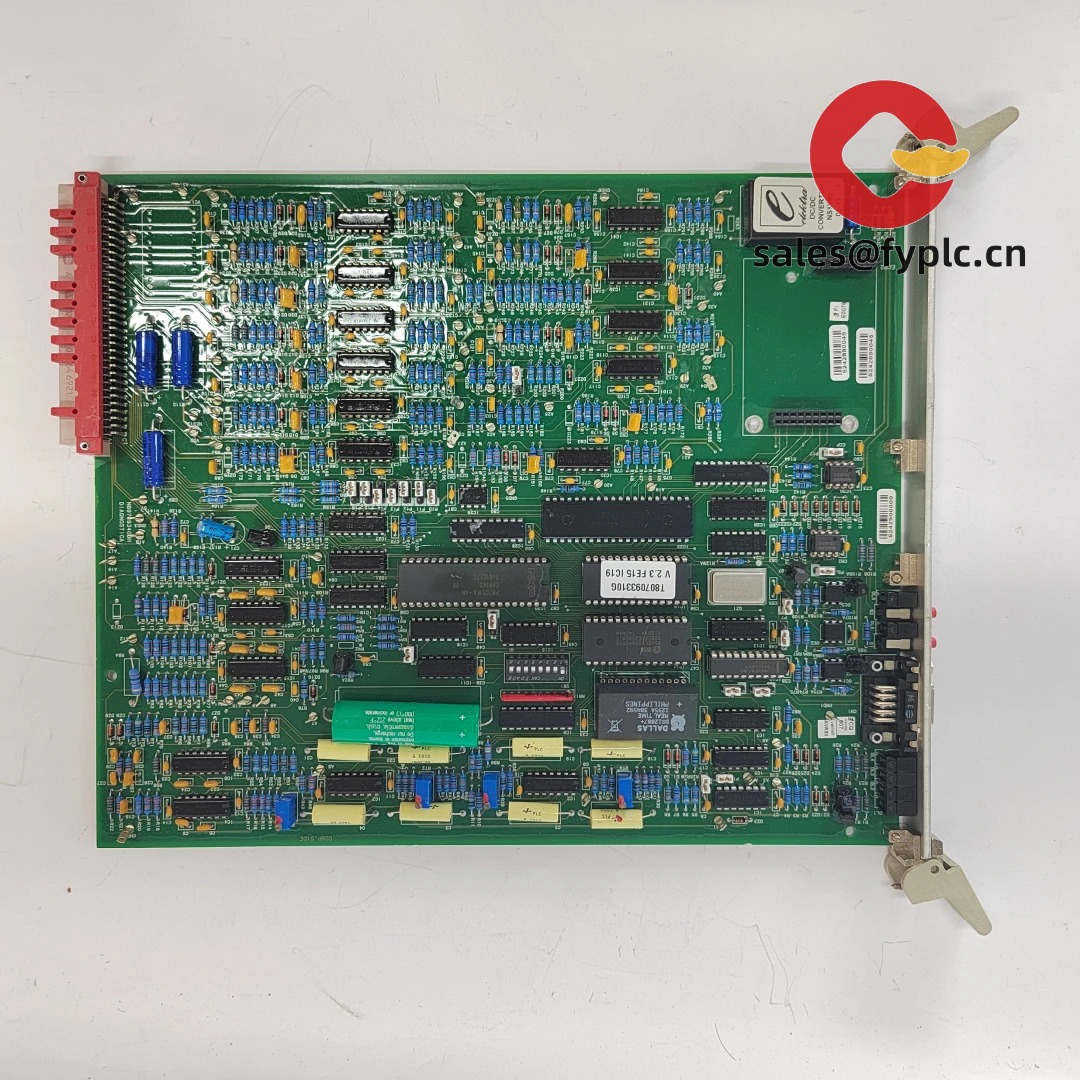

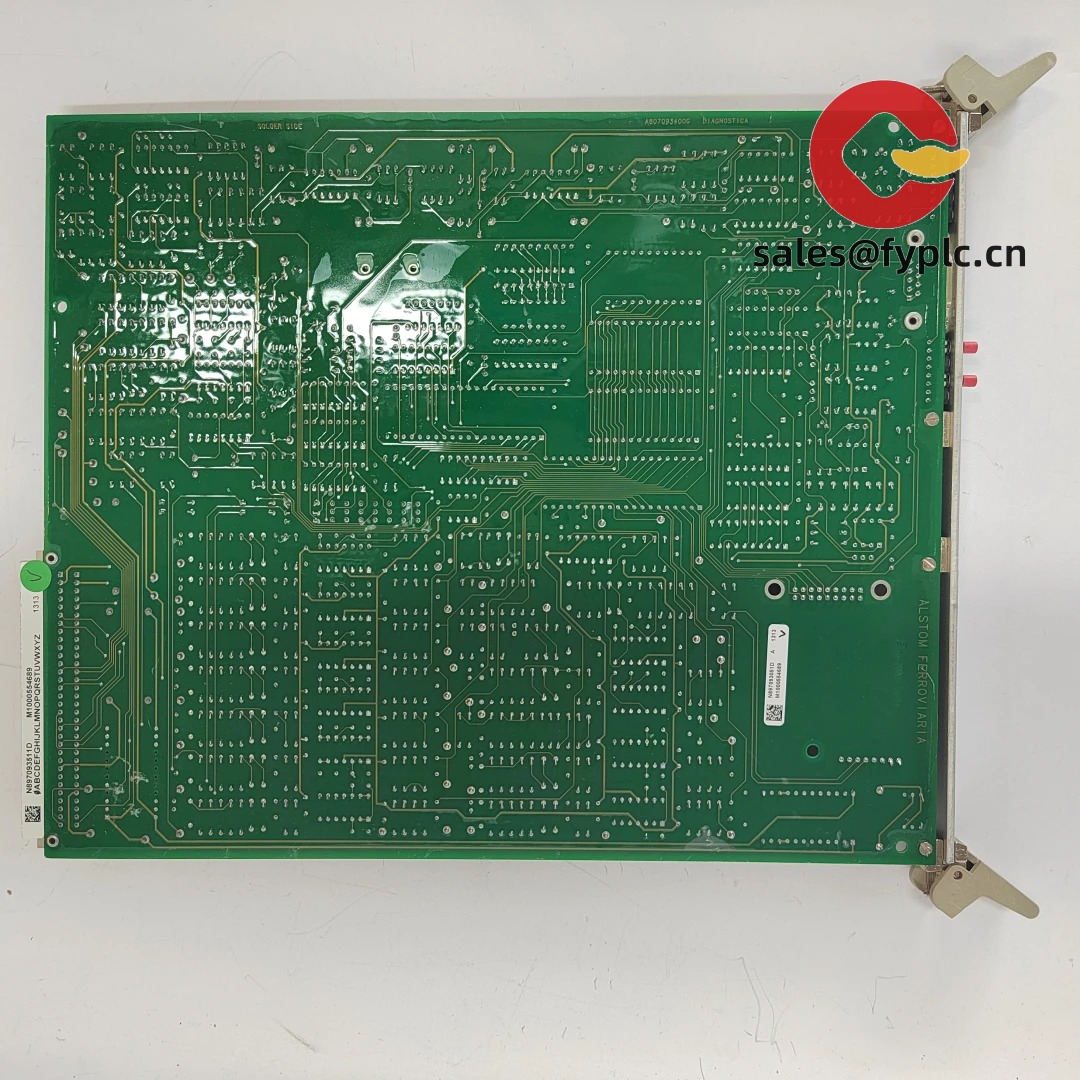

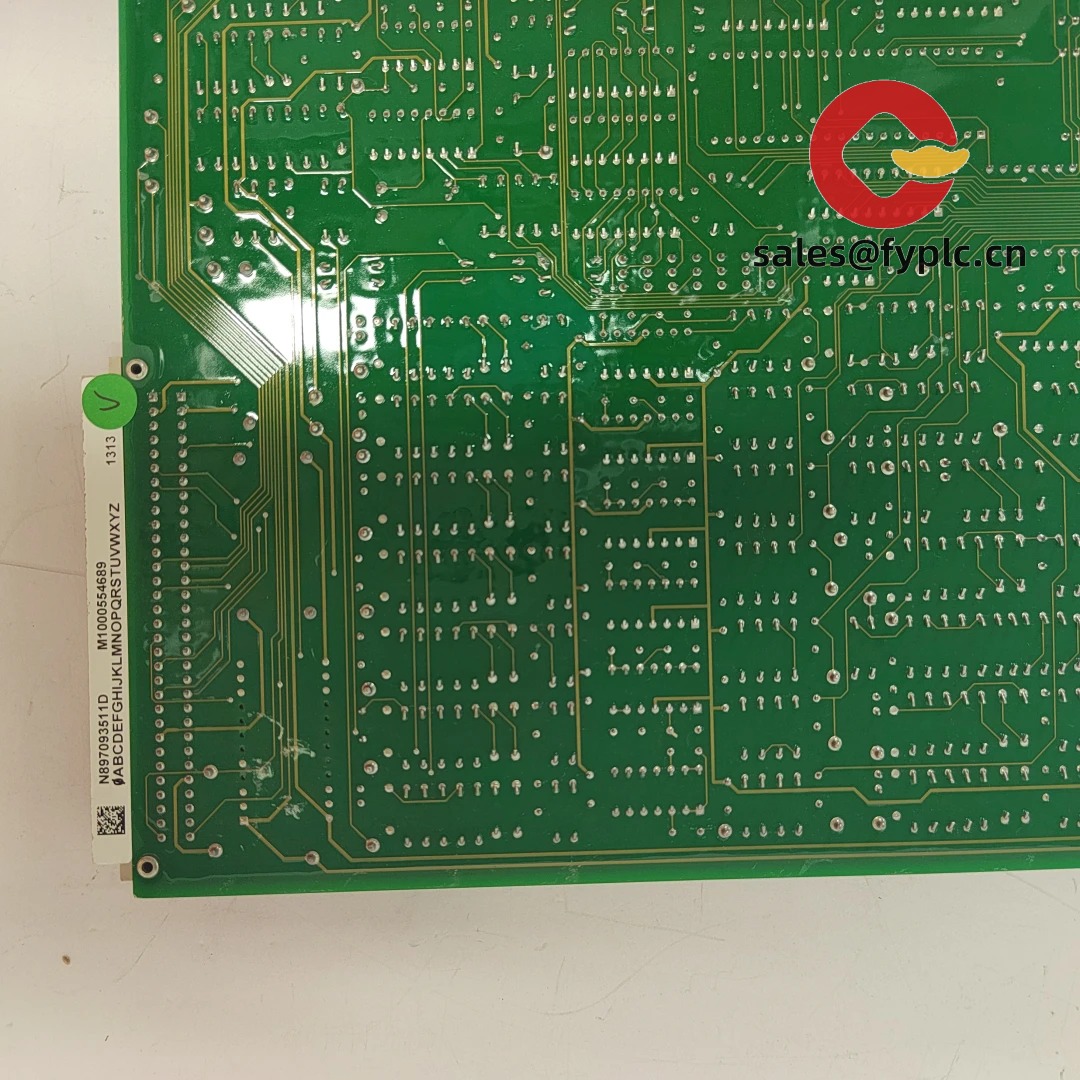

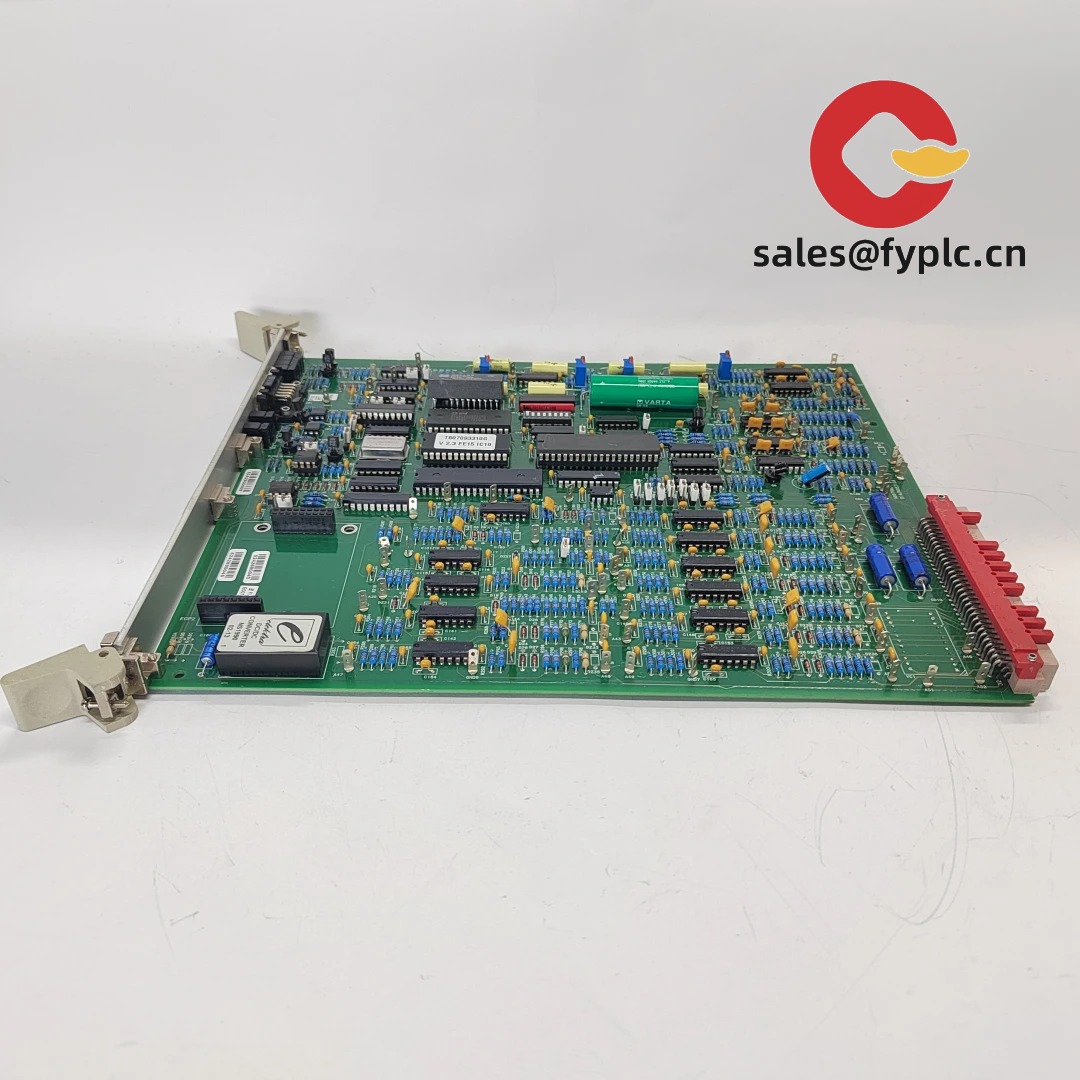

ALSTOM DIAGNOSTICA N897093511D / N897093051D / N897093400H – Diagnostic Interface Modules for Rail Control and Rolling Stock Systems

These ALSTOM DIAGNOSTICA modules—models N897093511D, N897093051D, and N897093400H—are typically used as diagnostic and status-interface boards within train-borne or wayside control systems. From my experience, they slot neatly into existing Alstom cabinets and help maintenance teams visualize health data, alarms, and system states without reworking the PLC/ATO/ATP logic you already have in service. You might notice that procurement teams value them as direct OEM replacements with predictable behavior during retrofit and routine overhaul windows.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days standard coverage

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Process: Share your model and quantity → confirm availability and test report → issue PI and arrange payment → functional test and packing → ship with tracking

Key Features

- OEM fit for Alstom cabinets – Designed to integrate with existing Alstom racks and wiring layouts, minimizing reengineering effort.

- Diagnostic visibility – Collects equipment states and alarms, helping depots pinpoint faults faster and reduce train downtime.

- Multiple I/O types – Typically supports digital status inputs and a relay/alarm output for simple annunciation chains.

- Service/maintenance ports – In many cases provides RS-232/RS-485 service access; certain variants are seen with Ethernet utility access.

- 24 VDC rail supply – Suited for rolling stock and wayside control cabinets where 24 VDC is the norm.

- Rugged construction – Built for the vibration, EMC, and thermal demands of rail environments.

- Drop-in replacement – One thing I appreciate is how these boards usually require no application code changes when replacing the same part number.

Technical Specifications

| Brand / Models | ALSTOM DIAGNOSTICA – N897093511D / N897093051D / N897093400H |

| HS Code (reference) | 8537.10 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typ. 19–32 VDC), ripple within standard rail tolerances |

| Operating Temperature | Typically -25°C to +70°C (model-dependent; confirm per submodel) |

| Signal Input/Output Types | Digital status inputs (dry contact or 24 V), relay/alarm output; onboard service indicators |

| Communication Interfaces | Service RS-232 / RS-485; Ethernet 10/100 on certain variants (verify per model) |

| Installation Method | Cabinet-mounted plug-in card or DIN-rail carrier; pluggable terminal connectors; IP20 when installed |

| Dimensions & Weight | Compact module; typically around 120 × 25 × 130 mm; ~0.25 kg (varies by submodel) |

Application Fields

- Rolling stock control cabinets (ATO/ATP/TCMS auxiliary diagnostics)

- Wayside interlocking and signalling cabinets where local diagnostic status is required

- Depot and maintenance benches for fault reproduction and event logging

- Retrofit projects replacing legacy diagnostic boards during mid-life overhauls

Advantages & Value

- Risk reduction: Direct compatibility with Alstom architectures avoids requalification cycles in most cases.

- Faster turnaround: Drop-in design keeps vehicle dwell time short; a depot engineer told us it was a “true swap-and-go” for their fleet.

- Lifecycle support: Access to test reports and traceable batches simplifies approvals and documentation.

- Cost control: Reduces troubleshooting hours and spare inventory by standardizing on known-good modules.

- Scalable spares plan: We can align batch deliveries to your maintenance calendar to avoid overstock.

Installation & Maintenance

- Cabinet conditions: Mount in a sealed control cabinet meeting EN and rail EMC practices; allow ventilation and avoid heat sources.

- Wiring: Use shielded twisted pair for RS-485; maintain clean 24 VDC power with correct polarity and protective earth.

- Commissioning: Verify LED states and service port connectivity; capture baseline logs after first power-up.

- Routine care: Quarterly connector reseat and dust removal; annual functional check of inputs/outputs and alarm relays.

- Firmware/config: If the variant supports it, keep configuration backups and apply updates during scheduled maintenance windows.

- Safety: De-energize the cabinet before handling; ESD protection is recommended when swapping boards.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- CE conformity and RoHS directives applicable to electronic assemblies

- Designed for railway environments; variants are typically aligned with EN 50155 and EN 50121-series requirements (confirm per submodel)

- 365-day warranty provided by our side on supply

Related/Supporting Components

- Shielded RS-485 harness kits for cabinet runs

- Panel-mount service adapters (DB9 to RJ45 for maintenance ports)

- DIN-rail carriers and pluggable terminal blocks compatible with Alstom layouts

- Industrial 24 VDC power filters to stabilize supply during cranking and dips

If you share which of the three models is your priority (N897093511D, N897093051D, or N897093400H), I can confirm exact I/O mapping and any interface differences. Lead times are currently favorable, and we can reserve stock against your overhaul plan.

Reviews

There are no reviews yet.