Description

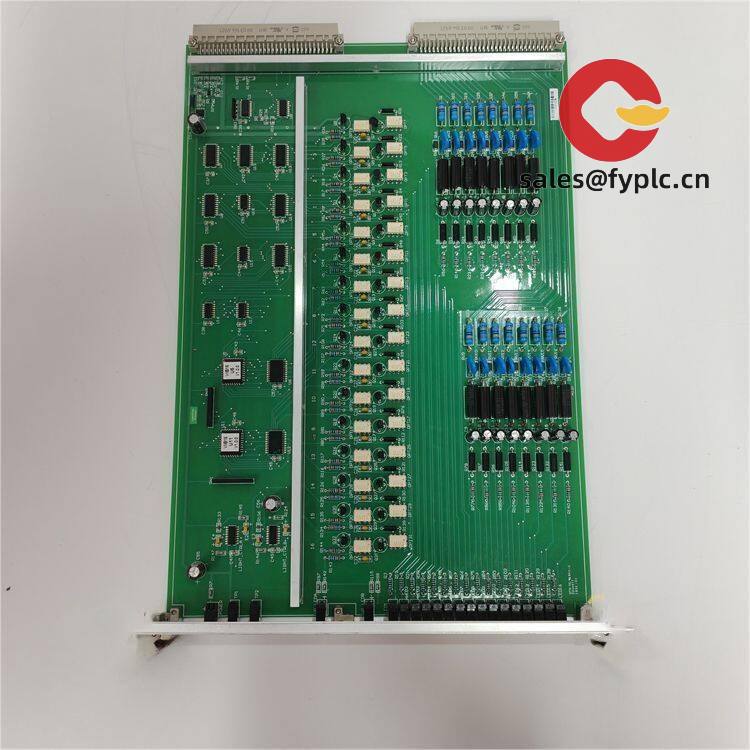

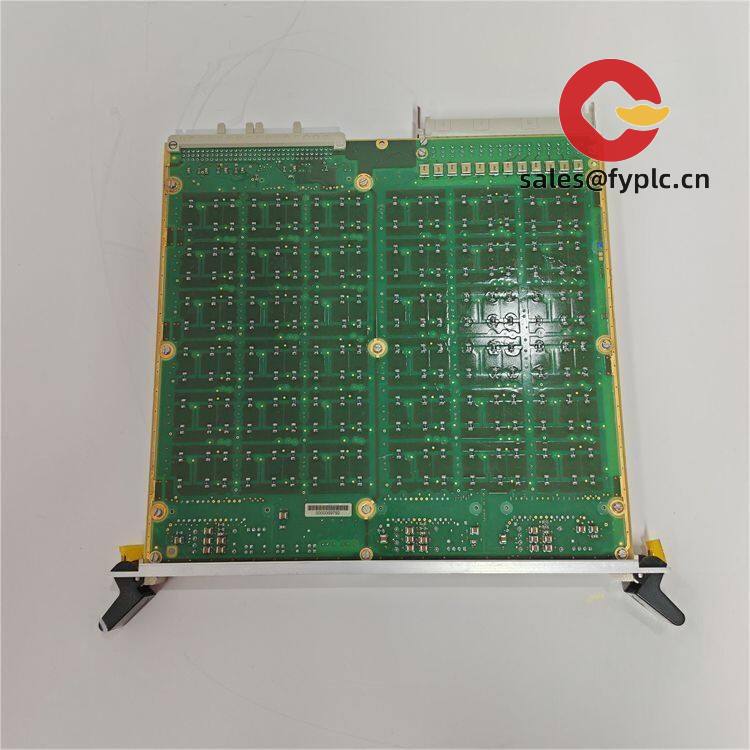

ALSTOM DSI1817-TRVC062335000-CP00003934 – Control Interface Board for Alstom Industrial and Rail Systems

The ALSTOM DSI1817-TRVC062335000-CP00003934 appears to be a DSI-series control/interface board used inside Alstom system racks—typically for traction, signaling, or turbine/plant control cabinets where high reliability and clean integration are non‑negotiable. From my experience, this kind of module handles mixed I/O and backplane communications, acting as a reliable bridge between field signals and the higher‑level controller. You might notice that the part coding includes DSI and a TRVC/CP suffix; in many cases that points to a specific build/revision traceable in Alstom BOMs.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Packaging: anti-static protection, shock-tested carton; moisture indicators for long-haul shipments

Key Features

- Rack-mounted board-level design – Slides into Alstom control cabinets, connecting through a system backplane for quick replacement and minimal wiring changes.

- Mixed-signal handling – Typically supports a combination of digital and analog channels, making it practical for complex field interfaces.

- Backplane communications – Proprietary bus interface for deterministic signaling within the Alstom rack, keeping noise and wiring complexity down.

- Industrial temperature performance – Designed for cabinet-mounted operation in typical plant or rolling-stock environments.

- Service-friendly front panel – Usually includes status indicators and retention screws, so technicians can see health at a glance and swap cards safely.

- Conformal coating options – In many cases, DSI-series boards include protective coatings to resist dust and humidity in harsh sites.

Technical Specifications

| Brand / Model | ALSTOM DSI1817-TRVC062335000-CP00003934 |

| HS Code | 8537.10 (Boards/panels/consoles for electric control, ≤1000 V; typical classification) |

| Power Requirements | Backplane-supplied low-voltage DC; 24 VDC nominal is typical in Alstom control racks |

| Operating Temperature | 0 to +55 °C ambient (cabinet-mounted, typical industrial range) |

| Signal I/O Types | Mixed digital/analog I/O via front connectors and backplane; opto-isolated digital channels common on DSI-series |

| Communication Interfaces | Proprietary rack backplane bus; service/test points depending on revision |

| Installation Method | Slide-in rack card with guide rails and front-panel retention screws; mates to system backplane |

Application Fields

This module is typically deployed in:

- Rail traction control cabinets and vehicle subsystems where robust I/O and deterministic backplane comms are required.

- Railway signaling/interlocking rack systems with redundant controller architectures.

- Power generation and plant control (turbine auxiliaries, balance-of-plant I/O marshalling) inside Alstom cabinets.

- Industrial process cabinets using Alstom racks, especially where mixed analog/digital field signals must be conditioned.

A maintenance manager told us the swap time was under 10 minutes during a night shift—“the backplane latch-up was clean, LEDs came up as expected, and the trend logs stabilized right away.”

Advantages & Value

- Reliability – Built for continuous operation in cabinet environments; proven in rail and plant applications.

- Compatibility – Fits Alstom rack ecosystems, reducing integration risk and avoiding rewiring in most cases.

- Lifecycle support – Helps extend service life of installed Alstom systems, deferring costly full-platform upgrades.

- Cost control – Lower downtime and faster swap reduce OPEX; standard logistics via DHL/UPS/FedEx keep projects on schedule.

- Technical backing – From part identification to revision matching, we typically assist with BOM cross-checks to ensure the right fit.

Installation & Maintenance

- Cabinet requirements – Install in a clean, ventilated control cabinet; maintain ambient 0–55 °C and avoid condensation.

- Wiring – De-energize the rack; seat the card on guide rails; ensure firm backplane engagement; torque front-panel screws gently to avoid PCB stress.

- Grounding & EMC – Ensure cabinet grounding is intact; route I/O cabling away from high-noise power lines; use shield terminations per Alstom grounding practices.

- Routine checks – Visual inspection for dust and connector wear every 6–12 months; clean with ESD-safe methods.

- Calibration & firmware – If the system uses calibration constants or firmware mappings, verify after replacement and document the revision in maintenance logs.

- Spares strategy – Keep at least one tested spare on-site for critical lines; store in anti-static packaging at controlled humidity.

Quality & Certifications

- CE compliance typically applicable for cabinet-installed control electronics.

- UL and/or CB scheme may apply at the cabinet/system level; verify per project documentation.

- RoHS/REACH conformance depends on revision and market; we can help check by part code.

- ISO 9001-based quality management followed during handling and test.

- Manufacturer warranty practices vary by region; our supply includes a 365-day warranty as stated.

Supporting Components (Typical)

- Alstom rack backplane compatible with DSI-series cards

- Front-panel harness or terminal block assemblies matching the DSI1817 pinout

- Shielded I/O cable sets for analog and discrete signals

- Redundant power supply module (24 VDC nominal) within the same cabinet

Note: The HS classification shown (8537.10) is a common listing for control boards/panels and is used by many importers for similar modules; final HS Code should be validated against your customs broker with the specific shipping configuration.

Reviews

There are no reviews yet.