Description

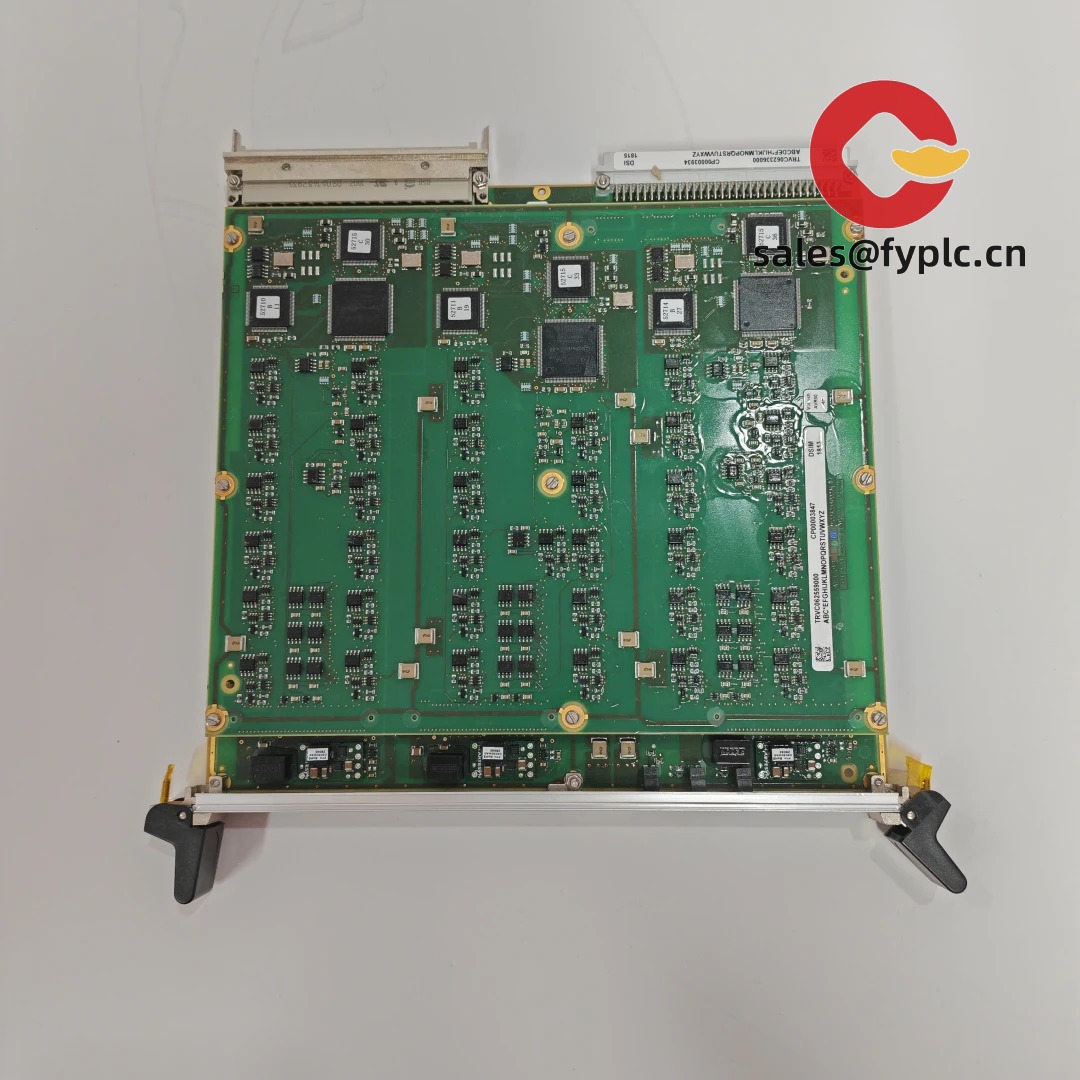

ALSTOM DSI1817 TRVC062335000 CP00003934 – Control Interface Board for Traction/Converter Systems

The ALSTOM DSI1817 (part code TRVC062335000, configuration CP00003934) is a control interface board typically used in ALSTOM traction converters, auxiliary power systems (SIV), and related propulsion control racks. From my experience, this board sits in the converter control crate and handles conditioned I/O and internal communications to coordinate firing logic, protection thresholds, and status reporting. You might notice that the TRVC and CP identifiers map to ALSTOM’s internal build/configuration sequences, which helps with ensuring form-fit-function replacement in installed fleets.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Form-fit-function replacement – Built to match DSI1817/TRVC062335000 CP00003934 footprints and connector layouts for quick swap-in.

- Backplane-powered design – Typically powered via the control rack, minimizing field wiring changes.

- Industrial-grade I/O conditioning – Handles mixed signal types used in propulsion control (isolated digital lines and conditioned analog channels).

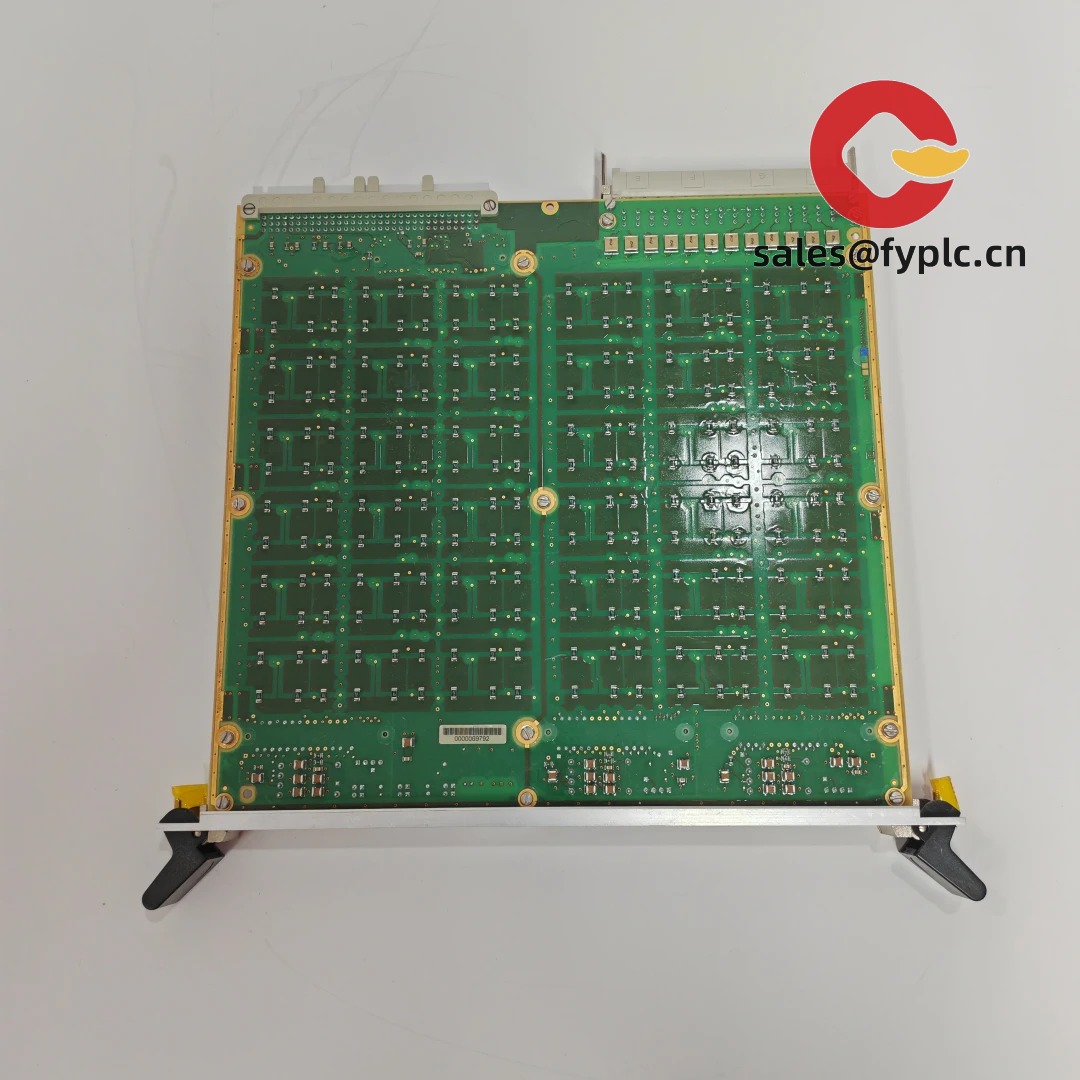

- Robust build for transport environments – Conformal coating and vibration-resistant construction are common on ALSTOM rail builds.

- Diagnostics-ready – Status LEDs and a service serial interface (in many cases) help with commissioning and fault tracing.

- Compatibility with ALSTOM converter racks – Integrates with standard ALSTOM control crates and DIN 41612–style backplane connectors in most versions.

- Stable operation across wide temperatures – Suitable for rolling-stock cabinets where ambient conditions vary.

Technical Specifications

| Brand / Model | ALSTOM DSI1817 / TRVC062335000 / CP00003934 |

| HS Code | 8538.90 – Parts suitable for electrical control apparatus |

| Power Requirements | Backplane supplied, 24 VDC nominal in most racks; low power (<10 W typical) |

| Dimensions & Weight | Eurocard-style PCB, approx. 100 × 160 mm; <0.3 kg (may vary by revision) |

| Operating Temperature | Typically −25 °C to +70 °C (cabinet-compliant; application dependent) |

| Signal I/O Types | Isolated digital I/O via backplane; conditioned analog inputs (e.g., 0–10 V or 4–20 mA where fitted) |

| Communication Interfaces | Proprietary rack/backplane bus; RS‑485 (Modbus RTU) or service serial port on many builds |

| Installation Method | Rack-mounted card; front insertion with captive fixings; DIN 41612–style connector (most versions) |

Application Fields

The DSI1817 family is commonly integrated in:

- Traction converters for EMUs, locomotives, and metro cars

- Static inverters (SIV) and auxiliary power converters on rolling stock

- Propulsion control cabinets coordinating gating, feedback, and protection thresholds

One thing I appreciate is how it slots into existing ALSTOM control racks without reworking harnesses—especially useful during mid-life overhauls when downtime is tight.

Advantages & Value

- Reliability in rail environments – Designed for vibration and thermal cycling typically seen in traction cabinets.

- Drop-in compatibility – Keeps software and wiring changes to a minimum, reducing commissioning effort.

- Lifecycle support – Helpful for sustaining fleets where the exact TRVC/CP build matters for interchangeability.

- Cost control – Short lead times help cut spare inventory holding costs and avoid prolonged vehicle outages.

- Technical assistance – Parameter mapping and revision cross-checks available upon request.

“We replaced a failing converter card on a six-car set; the DSI1817 went in cleanly and our test crew had propulsion back within the same shift.” — Maintenance Supervisor, commuter rail (shared with permission)

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet; observe IP rating of the enclosure. Maintain clearance for airflow around the rack.

- Wiring and ESD – De-energize the rack, follow ESD precautions, and seat the card fully into the backplane. Verify keying before insertion.

- Grounding – Ensure cabinet PE bonding is intact; noise immunity depends on proper grounding in traction environments.

- Configuration – Match the CP00003934 configuration to the vehicle set; back up parameters before replacement.

- Routine checks – Visual inspection every service interval; clean light dust with dry air; check connectors for fretting.

- Calibration/firmware – Some builds require calibration data or firmware alignment; keep records synchronized with fleet documentation.

Quality & Certifications

- CE marking applicable for EU deployments

- Manufactured under ISO 9001 quality systems

- RoHS compliance in most EU-delivered configurations

- Railway standards such as EN 50155/EN 50121 are typically referenced for rolling-stock builds

- Manufacturer’s warranty: 12 months (365 days)

Related/Supporting Components

- ALSTOM control rack/backplane compatible with DSI-series cards

- 24 VDC rack power supply module (for backplane feed)

- DIN 41612 mating connector hardware and card guides

- Service cable for RS‑485/serial diagnostics (where applicable)

Note: Specifications above reflect typical DSI1817/TRVC builds used in traction and auxiliary converter applications. Minor differences can exist between revisions. If you share your vehicle type and rack reference, we can validate compatibility against CP00003934 before shipping.

Reviews

There are no reviews yet.