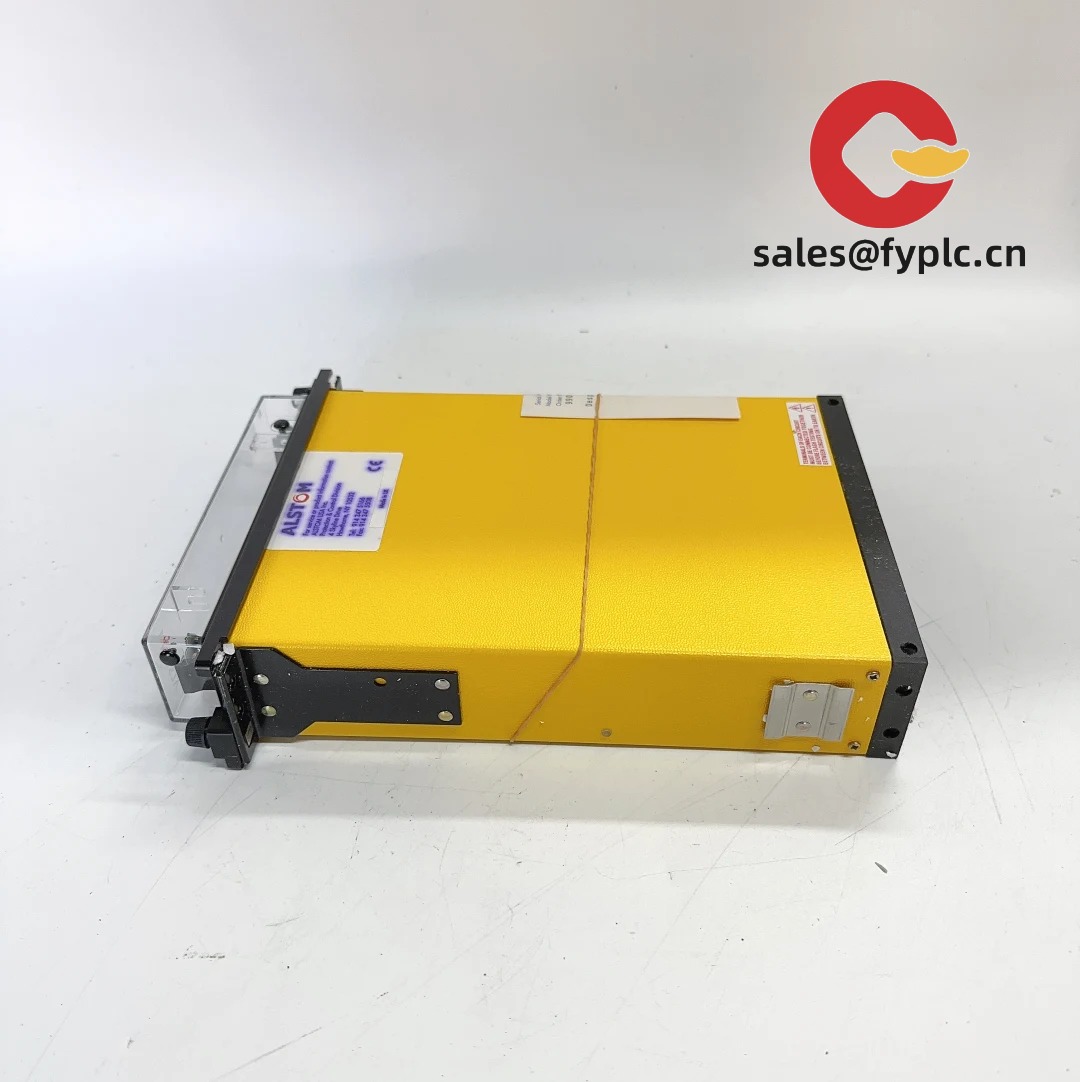

Description

ALSTOM MVAW11B1AB9007A – Auxiliary Protection Relay for Trip/Interlock Duties in Power Systems

The ALSTOM MVAW11B1AB9007A is part of the classic MV-series auxiliary relays used across substations, power plants, and industrial switchgear. From my experience, the “MVA” family is chosen when engineers want a hardwired, dependable relay to drive breaker trip coils, duplicate signals, or manage interlocks without adding complexity. The MVAW11 variant typically denotes a single-element, changeover-contact design aimed at reliable DC operation in protection panels.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Hardwired reliability – Pure electromechanical design with no firmware; in many cases preferred for critical trip/interlock tasks.

- Single changeover output – MVAW11 series is commonly configured with one Form C (SPDT) contact for simple, robust control logic.

- DC coil variants – Typically offered in 110 VDC or 220 VDC coils (other DC voltages exist in the family), helping match existing panel supplies.

- High contact rating – Suited for breaker trip coil duty and signal duplication; seems to handle resistive loads comfortably in utility panels.

- Panel-friendly mounting – Designed for protection cubicles and switchgear doors; straightforward wiring and maintenance.

- Noise-tolerant operation – Good immunity to substation noise compared with sensitive electronic inputs.

Technical Specifications

| Brand / Model | ALSTOM MVAW11B1AB9007A |

| HS Code | 8536.49.00 (Relays for a voltage > 60 V) |

| Power Requirements | DC coil (variant-dependent; commonly 110 VDC or 220 VDC in this series) |

| Signal I/O Types | Coil input (DC); 1x Form C (SPDT) dry contact output typical of MVAW11 |

| Communication Interfaces | None (hardwired relay) |

| Installation Method | Panel/switchgear mounting in protection cubicles; front-wired terminals |

| Operating Temperature | Typically -10°C to +55°C for this family (check nameplate for the specific unit) |

| Dimensions & Weight | Compact relay case; variant-specific. We can verify exact case size against the MVAW11B1AB9007A plate. |

Application Fields

You might notice that utilities and EPCs keep these relays on BOMs for the “must-work” links in a scheme. Typical uses include:

- Substation breaker tripping and closing interlocks

- Signal duplication and galvanic isolation for SCADA/RTU inputs

- Lockout, blocking, and permissive logic in protection panels

- Turbine/generator and plant auxiliaries where a dedicated hardware relay is preferred

- Process safety tie-ins where fail-safe, visible hardwiring is requested

Advantages & Value

- Dependable sourcing – Helpful for maintaining legacy ALSTOM/GEC protection panels without redesign.

- Compatibility – Works cleanly with DC trip circuits, MiCOM/Agile relays, and common RTU I/O—no protocol headaches.

- Lifecycle savings – Minimal commissioning effort and practically zero firmware maintenance.

- Support – We can cross-check coil voltage, contact arrangement, and mounting details by serial to avoid misorders.

Customer feedback (utility O&M lead): “We swapped an older auxiliary with an MVAW11 unit last outage—wiring matched our drawing, and trip timing stayed consistent. It’s been trouble-free.”

Installation & Maintenance

- Panel/cabinet – Install in a clean, dry IEC-rated enclosure with basic ventilation. Keep DC supply within the specified coil range.

- Wiring – Use ferruled, labeled conductors; segregate DC trip wiring from high-noise conductors where practical. Verify polarity on DC coils.

- Commissioning – Perform a contact continuity check, coil pickup test at nominal and at -10%/-15% supply if required by site procedures.

- Routine maintenance – Periodic functional trip checks; inspect terminals for looseness; clean dust with dry air; replace if contact wear or discoloration is evident.

- Safety – Isolate DC supplies, verify zero energy, and tag before handling. Where fitted, observe arc-suppression networks across coils.

Quality & Certifications

- Manufactured within ALSTOM/GE Grid Solutions quality systems (typically ISO 9001)

- CE marking customary for EU markets; RoHS applicability depends on production year and configuration

- Utility-proven electromechanical design with long field history

- Standard warranty: 365 days

Reviews

There are no reviews yet.