Description

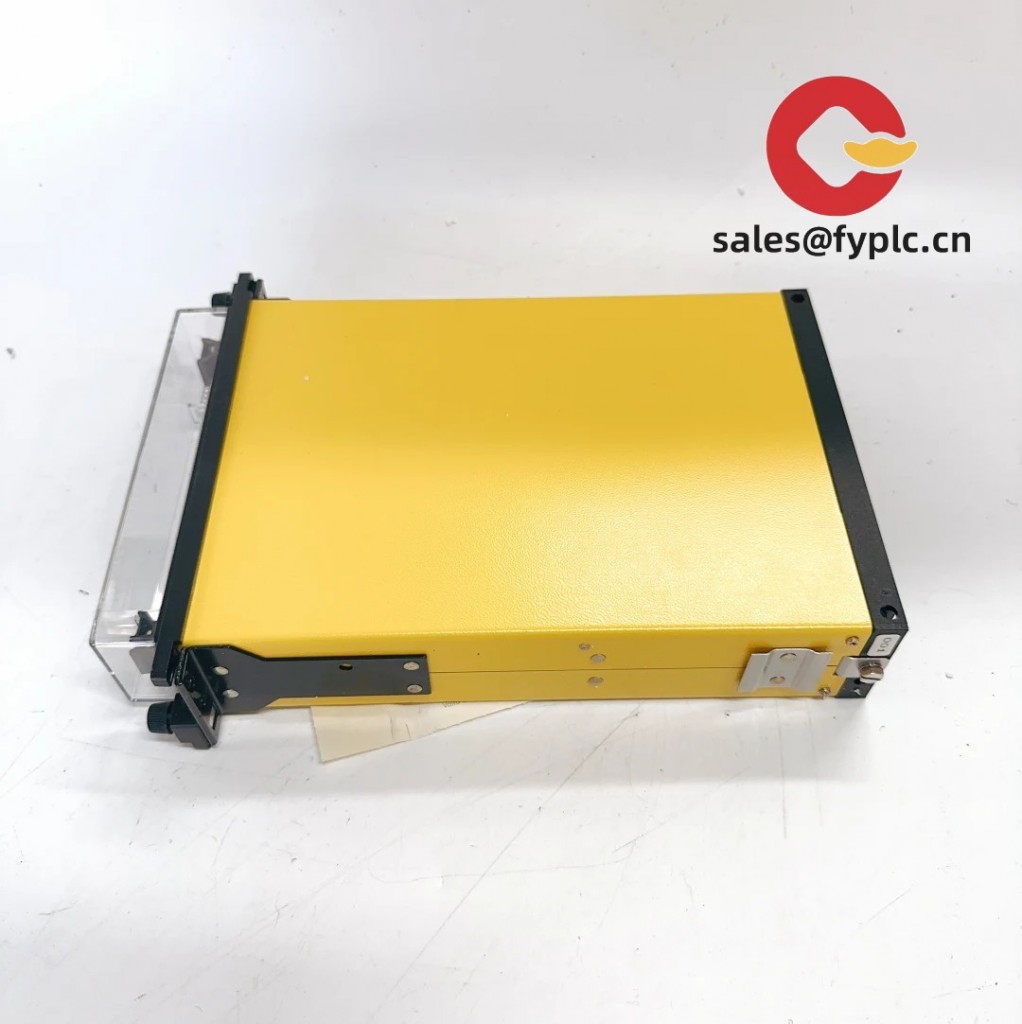

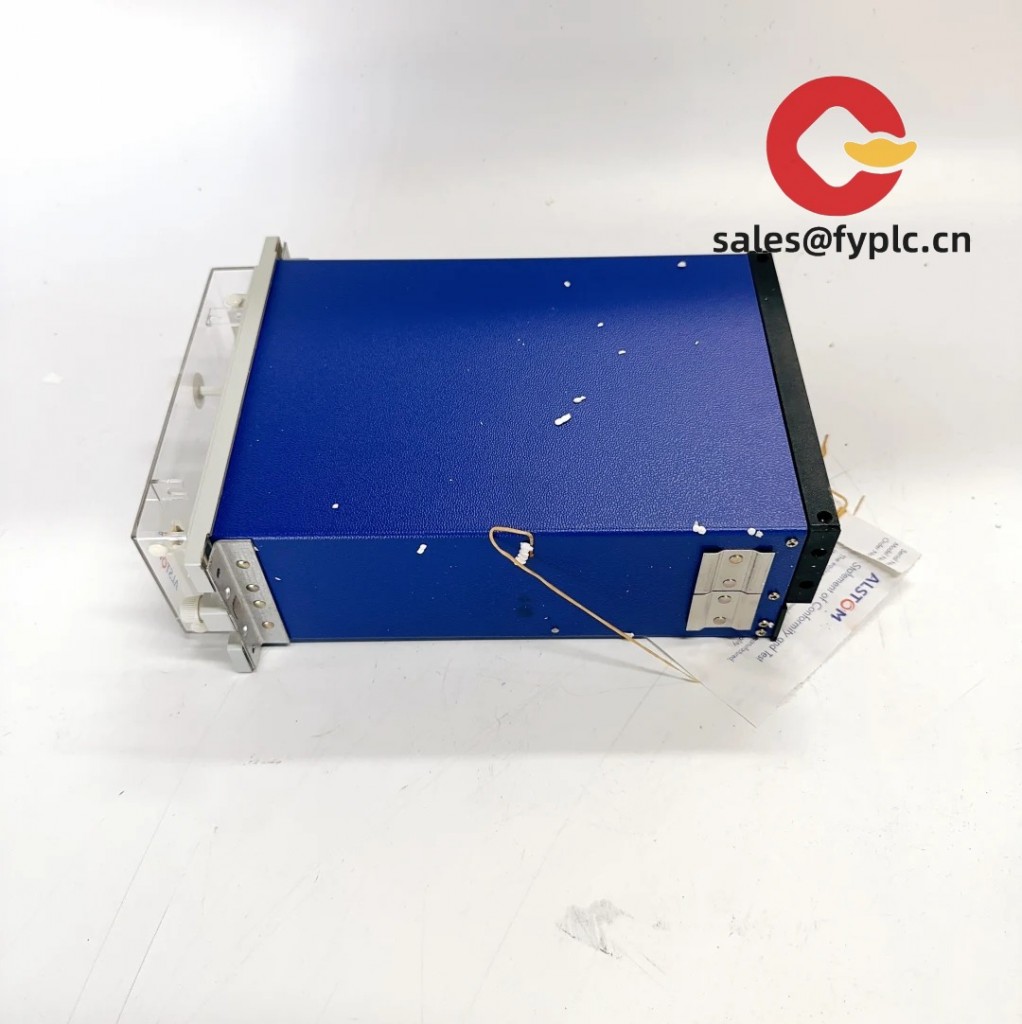

ALSTOM MVTT14B1BA0773C – Plug‑In Turbine Control Module for Legacy ALSTOM Racks

The ALSTOM MVTT14B1BA0773C is a plug‑in control module used widely in legacy ALSTOM steam and gas turbine control cabinets. From my experience, this series sits in the turbine logic/sequence layer, bridging field signals through the rack backplane and executing protection or interlock functions that plants rely on every day. If you’re maintaining an existing ALSTOM cabinet and need a form‑fit‑function spare, this board typically drops in without wiring changes or software rewrites.

Order Placement Process and Guarantees

-

- – Warranty period: 365 days from shipment

-

- – Delivery: 1 week for in‑stock items; no more than 1 month latest

-

- – Payment: 50% advance payment; full payment prior to delivery

- – Express options: FedEx, UPS, DHL (export‑ready packing)

Each unit is function‑tested before dispatch and packed for vibration and ESD protection. You might notice that replacement time on site is quick—typically a simple slide‑in, tighten the front screws, and reseat. We can also provide basic power‑on checks so you’re not guessing once the cabinet is live.

Key Features

- Native rack compatibility – Designed for ALSTOM MVTT‑series control racks; form‑fit‑function replacement in most cabinets.

- Backplane power and I/O – No external power input; signals and communication handled via the proprietary ALSTOM backplane.

- Industrial signal conditioning – Typically supports mixed discrete/analog channels through the rack, suitable for turbine sequencing and protection logic.

- Robust construction – In many cases conformal‑coated for humidity and dust resistance; ruggedized connectors for cabinet vibration.

- Service‑friendly – Front panel retention screws and card guides make installation straightforward; minimal downtime during changeout.

- Lifecycle support – Useful for maintaining legacy ALSTOM turbine controls where like‑for‑like spares reduce operational risk.

Technical Specifications

| Brand / Model | ALSTOM MVTT14B1BA0773C |

| HS Code | 853890 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Supplied via ALSTOM rack backplane (low‑voltage DC from system power supply) |

| Operating Temperature | Typically 0–55°C in a ventilated control cabinet; non‑condensing humidity |

| Signal I/O Types | Mixed discrete/analog via backplane; exact channel functions depend on cabinet configuration |

| Communication Interfaces | Proprietary ALSTOM backplane bus (no direct fieldbus on the front panel) |

| Installation Method | Slide‑in plug‑in module; secures with front screws; field wiring remains on terminal boards |

| Dimensions & Weight | Rack plug‑in PCB (6U‑class card height typical); lightweight module for single‑person handling |

Notes: Specifications above reflect typical characteristics for this ALSTOM series. Exact channel mapping and firmware level depend on your cabinet revision and slot assignment.

Application Fields

- Steam turbine control and protection cabinets (trip/sequence logic)

- Gas turbine legacy ALSTOM control racks needing form‑fit spares

- Balance‑of‑plant interlock handling and conditioned I/O within the turbine train

- Lifecycle maintenance, emergency spares, and planned overhauls

A maintenance lead at a combined‑cycle site told us this board “slotted straight in, cleared our trip fault, and saved a weekend restart”—which seems to be the common outcome when the slot and firmware match the cabinet records.

Advantages & Value

- Reduced downtime – Like‑for‑like replacement minimizes commissioning time.

- Compatibility assurance – We verify part/series and slot function against your cabinet BOM before shipment.

- Cost control – Extends life of existing assets; avoids immediate DCS migration costs.

- Proven reliability – Each unit is function‑tested; test report available on request.

- Technical support – Assist with slot assignment, jumper positions, and firmware level, typically within the same business day.

Installation & Maintenance

- Cabinet requirements – Install in a clean, ventilated control cabinet. Maintain ambient 0–55°C, non‑condensing humidity.

- Wiring – No field rewiring; signals remain on terminal boards. Ensure backplane connectors are fully seated and front screws tightened.

- ESD and safety – Power down the rack segment if possible. Use ESD wrist strap and handle the board by edges.

- Routine care – Periodic dust removal with dry air, inspect edge connectors, and check any jumpers/dipswitches match cabinet records.

- Firmware/config – Where applicable, confirm firmware level and logic assignment for the specific slot; keep a spare imaged to your current revision.

Quality & Certifications

- CE compliance is typically associated at the cabinet/system level.

- UL/CSA may apply to the assembled control panel rather than the individual module.

- ISO 9001 quality management for handling, testing, and documentation.

- RoHS status varies by production date for legacy hardware; we can confirm by part revision.

- Warranty: 12 months (365 days) from shipment.

Related Components (for a complete solution)

- ALSTOM rack power supply modules (backplane LVDC feed)

- Terminal board assemblies and ribbon/cable harnesses

- Controller/CPU and sequence logic modules for the same rack family

- Spare backplane connectors and front panel hardware (screws, card guides)

Reviews

There are no reviews yet.