Description

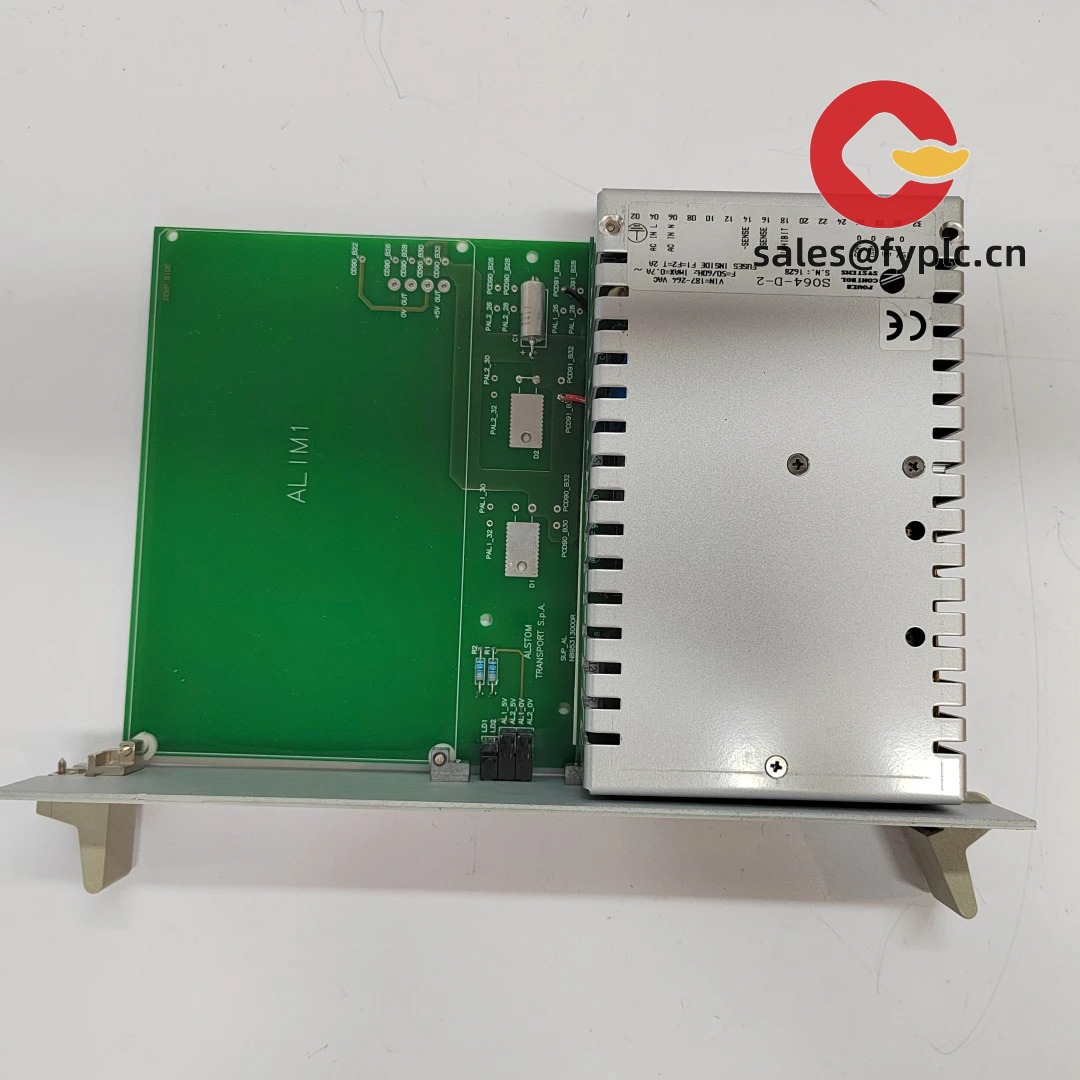

ALSTOM N895313512X / N95313012D (SUP-AL) / N895313000R – Supervision & Alarm Module for Control Cabinets

The ALSTOM part set N895313512X, N95313012D marked SUP-AL, and N895313000R refers to a supervision/alarm board typically used inside ALSTOM control and propulsion cabinets. From my experience, this module consolidates cabinet status, power supply health, and alarm signaling back to the host controller through the rack backplane. It’s a straightforward drop-in for maintenance teams who need a like-for-like replacement without rewriting logic or changing wiring.

You might notice that SUP-AL appears on the faceplate or PCB silkscreen; that’s common on ALSTOM supervision boards. The three codes above often represent compatible revisions or related assemblies, so if you’re replacing a fielded unit, we can match by part number, serial tag, or photo to ensure slot and firmware alignment.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month latest

- Payment: 50% advance; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Traceability: photos and test report before shipment upon request

Key Features

- OEM-grade compatibility: Built to match ALSTOM rack/backplane interfaces, so it typically installs without rewiring.

- SUP-AL functionality: Aggregates cabinet status and alarms; simplifies diagnostics for propulsion or auxiliary systems.

- Revision-friendly sourcing: N895313512X, N95313012D (SUP-AL), and N895313000R covered as compatible or successive revisions in many cases.

- Stable 24 VDC control power: Designed for control-cabinet supply rails, reducing integration risk.

- Serviceability: Front-access installation with rack guide; quick swap minimizes downtime on the line.

- Quality-screened: Units are function-checked prior to shipment; we can share records on request.

Technical Specifications

| Brand / Model | ALSTOM – N895313512X / N95313012D (SUP-AL) / N895313000R |

| HS Code | 8538.90 (Parts for switching/protection/control gear) – typical classification |

| Power Requirements | 24 VDC nominal from host control cabinet (verify against the label of your existing unit) |

| Operating Temperature | Control-cabinet environment, non‑condensing humidity; typically -10 to +55°C |

| Signal I/O Types | Digital status inputs and alarm outputs via rack backplane; channel count depends on revision |

| Communication Interfaces | Backplane interface to ALSTOM controller; service/diagnostic header where applicable |

| Installation Method | Rack-mounted board; front insertion into the designated slot, secured on the front plate |

| Form Factor | Board-level assembly for ALSTOM cabinet slot; compact and lightweight for field service |

Application Fields

- Rolling stock propulsion and auxiliary power cabinets (supervision and alarm consolidation)

- Wayside control racks in depots or traction power rooms, where ALSTOM control platforms are installed

- Test benches and refurbishment lines needing form-fit-function spare boards

- Lifecycle support for legacy ALSTOM systems during mid-life overhaul

Advantages & Value for Procurement

- Reduced downtime: Direct replacement minimizes troubleshooting time on critical fleets.

- Compatibility assurance: We cross-check by P/N and revision so your software and wiring remain intact.

- Cost control: Sourcing the correct revision the first time avoids repeat site visits.

- Technical support: Quick guidance on slot mapping, backplane pins, and handling—nothing flashy, just practical help.

- Documentation on request: Packing list, test record, and COC for QA traceability.

Installation & Maintenance

- Environment: Install in a clean, dry control cabinet with stable 24 VDC and proper ventilation; avoid condensing humidity.

- Handling: Use ESD protection. Power down the cabinet and isolate supplies before removal/installation.

- Fitment: Confirm the slot ID and keying before insertion; seat the backplane connector fully and secure the front plate.

- Wiring: Most connections are via backplane; verify any front connectors or headers if your revision includes them.

- Routine checks: Periodically inspect for dust and connector oxidation; clean gently with approved methods.

- Firmware/Settings: If the board stores configuration, back up and restore as per your maintenance procedure.

- Spares: Keep at least one tested spare per critical trainset or control rack—seems to be the sweet spot for availability.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (typical for ALSTOM supply chain)

- CE conformity where applicable to the host assembly; RoHS status can vary by revision and production date

- 365-day warranty coverage from shipment date

- Traceable serial numbers and test-before-ship process

Typical Supporting Components

To make installation smoother, many teams also request a few supporting pieces. One thing I appreciate is keeping these on hand during overhaul:

- DIN 41612 backplane connector (96-pin, Type C): Common on Eurocard-style ALSTOM racks; useful for backplane refurbishment.

- Front-plate fixing screws and extraction handle: For easy removal/install without stressing the PCB.

- 24 VDC cabinet fan/filter kit: Keeps air flow stable and extends board life in dusty depots.

- Diagnostic cable/adaptor: If your revision provides a service header, a simple USB-to-UART tool speeds checks.

“We swapped in the SUP-AL board (matched to N95313012D) during a night shift on a metro set. No logic changes, alarms cleared right away.” — Maintenance Manager, urban rail operator

Reviews

There are no reviews yet.