Description

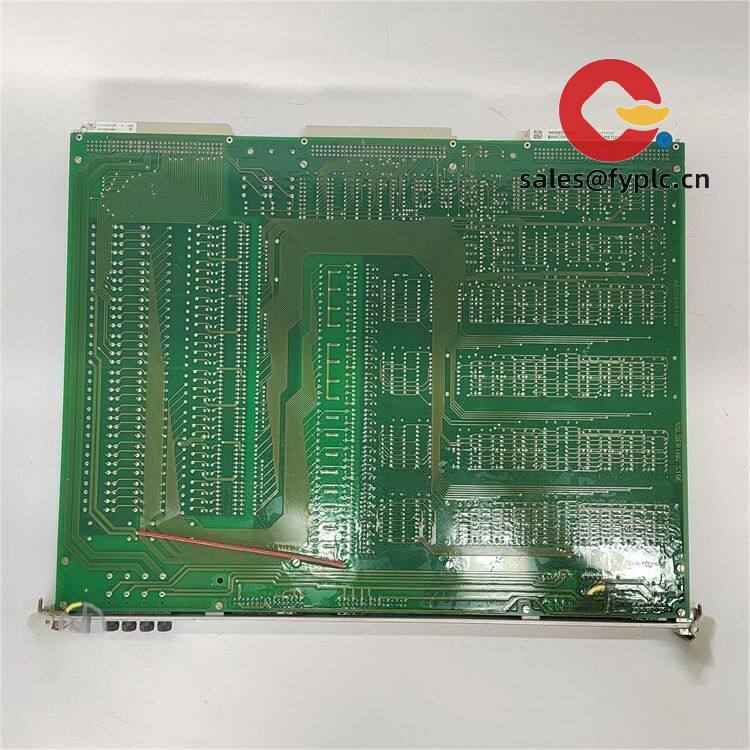

ALSTOM N895609510K‑N895609010R‑E32OUT‑N895609100P – Modular 32‑Channel Digital Output Assembly for Rail and Industrial Control

This configuration combines the ALSTOM controller card (N895609510K), a backplane/rack (N895609010R), the E32OUT 32‑channel digital output module, and a dedicated power unit (N895609100P). From my experience, this set is typically deployed as a reliable, rack‑mounted output node in signaling cabinets or industrial control panels where clean 24 VDC digital drive and long service life matter. You might notice that it’s designed to be a drop‑in OEM replacement for legacy cabinets, minimizing rewiring and commissioning time.

Our Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Integrated assembly – Includes controller (N895609510K), rack/backplane (N895609010R), 32‑point digital output (E32OUT), and power module (N895609100P); typically supplied as an OEM‑compatible set for quick replacement.

- 32‑channel digital outputs – E32OUT provides dense 24 VDC output points for lamps, relays, contactors, or wayside interface devices; helps consolidate wiring.

- Rack‑mounted design – Backplane architecture simplifies module changes and keeps field wiring intact; useful when downtime windows are tight.

- Stable 24 VDC operation – Designed around industry‑standard 24 VDC control power, which in many cases improves compatibility with existing cabinets.

- Serviceability – Front access to modules and terminals; you can swap boards without disturbing the bulk of field terminations.

- Long lifecycle support – Appears to be built for environments where parts continuity and maintainability are critical (rail depots, utility rooms, process lines).

Technical Specifications

| Brand / Model | ALSTOM N895609510K + N895609010R + E32OUT + N895609100P |

| Product Type | Rack‑mounted I/O output assembly (controller + backplane + 32‑DO module + power) |

| HS Code | 8537.10 (Boards/panels/consoles for control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (system supply via N895609100P) |

| Signal I/O Types | 32 digital outputs (24 VDC), suitable for driving relays, indicators, and low‑power actuators |

| Communication Interfaces | Backplane connection to controller (ALSTOM proprietary bus); system‑level interface depends on the controller card installed |

| Installation Method | Rack/backplane mounted inside control cabinet; front wiring via terminal blocks |

| Operating Temperature | Typically −20 to +55 °C (verify against site specification for the exact variant) |

Application Fields

- Rail signaling cabinets: wayside interlocking output banks, signal lamp driving, point machine interlocks.

- Transportation infrastructure: platform control outputs, tunnel ventilation relays, track‑side annunciators.

- Industrial automation: retrofit output expansion for process skids, utilities, and energy management panels.

- Power and utilities: substation control panels where dense 24 VDC outputs are preferred.

Advantages & Value

- Reliability – Built for continuous service; in many cases, these modules run for years with minimal intervention.

- Compatibility – Drop‑in with ALSTOM backplane systems; reduces engineering churn during maintenance windows.

- Cost control – Consolidates 32 outputs in one module; fewer parts, fewer spares, simpler stock management.

- Service support – We provide advance replacement options and technical guidance during commissioning when needed.

Installation & Maintenance

- Cabinet standards: install in a clean, ventilated control cabinet; 19‑inch rack or panel frame as per N895609010R rack requirements.

- Wiring: use ferruled conductors; segregate 24 VDC control wiring from higher‑power cables to reduce noise.

- Grounding: bond cabinet and backplane ground to facility earth; maintain proper shield terminations for field cables where applicable.

- Safety: de‑energize 24 VDC supply before inserting or removing modules; verify output loads are within the module’s rating.

- Routine care: dust the cabinet; periodically re‑torque terminals; perform functional I/O checks during scheduled outages.

- Firmware/config: if the controller card is updated, back up configurations and follow the site’s change‑control process.

Quality & Certifications

- CE compliant and RoHS aligned for industrial electronic assemblies (typical for this series).

- Manufacturer quality systems commonly aligned with ISO 9001.

- Warranty: 365 days (seller warranty).

One thing I appreciate is how maintenance teams can swap an E32OUT in minutes without touching the rest of the rack. A depot supervisor told us the “swap‑and‑test cycle” often stays under an hour, which seems to be the difference between a planned window and a late restart.

Reviews

There are no reviews yet.