Description

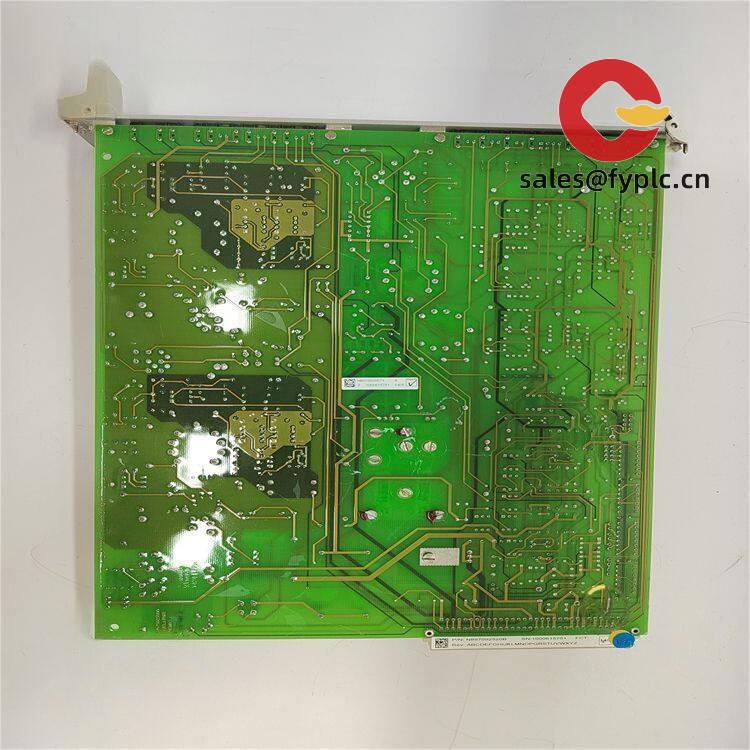

Alstom N897092520B–N897092057Y Propulsion Control PCB Set for Rolling Stock Maintenance

The Alstom N897092520B–N897092057Y combination is commonly supplied as a matched control/driver PCB set used inside traction converter or auxiliary converter racks on Alstom rolling stock. From my experience, these two boards are usually paired in the same bay and version-matched, so you reduce commissioning risks when you replace them together. For depots dealing with intermittent converter trips, irregular gate drive behavior, or converter self-diagnostics pointing to control-chain faults, this set typically brings the system back to stable service quickly.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Pre-shipment checks: visual inspection, connector integrity, functional verification where applicable

Key Features

- Matched control/driver pair – Supplied as N897092520B and N897092057Y to maintain firmware and hardware compatibility inside Alstom converter racks.

- Railway-grade design – Built for vibration, surge, and temperature swings typical of rolling stock environments, often aligned with EN 50155 practices.

- Backplane integration – Plug-in PCB format that mates to the converter’s proprietary backplane for power, I/O and internal communications.

- Signal conditioning and protection – Opto-isolated I/O and guarded low-level analog sensing for stable control feedback in noisy traction bays.

- Service-friendly handling – Front access, captive fasteners, and clear test points make depot replacement faster; one customer told me their swap-and-test took under 30 minutes.

- Version support – Suffix codes “B” and “Y” typically indicate hardware/firmware revisions; we help verify interchangeability against your converter build list.

Technical Specifications

| Brand / Model | Alstom N897092520B–N897092057Y |

| Product Type | Propulsion control PCB set (converter control/driver modules) |

| HS Code | 8538.90 (Parts suitable for electrical control equipment) |

| Power Requirements | 24 VDC nominal (from vehicle auxiliary supply/backplane) |

| Operating Temperature | Typically −25°C to +70°C (railway service conditions) |

| Signal I/O Types | Opto-isolated digital I/O, low-level analog sense inputs, driver outputs to converter power stage |

| Communication Interfaces | Proprietary backplane bus; service/test headers for depot diagnostics |

| Installation Method | Plug-in PCB for converter rack; front-panel retention screws; keyed connectors |

| Form Factor | Board-level assembly; compact, rack-insertable footprint |

Application Fields

This pair is used in rolling stock propulsion and auxiliary systems where Alstom converter platforms are installed:

- Traction converters for EMU/METRO/Locomotive propulsion

- Auxiliary converters and static inverters on passenger or freight fleets

- Dynamic/braking chopper control sections

- Converter bays interfacing with TCMS and vehicle diagnostics

Advantages & Value

- High availability – We focus on hard-to-find Alstom spares, which typically shortens downtime and avoids prolonged parked units.

- Version matching support – You might notice suffix differences across fleets; we verify compatibility against your converter serial/build list before shipping.

- Reduced risk – Boards are inspected and electrically verified where applicable; 365‑day warranty provides practical assurance in service.

- Cost-efficient lifecycle – Procuring the pair often avoids repeat interventions caused by mixed revisions, saving both labor and commissioning trips.

Installation & Maintenance

- Environment – Install in the original converter rack with adequate ventilation; keep dust and metallic debris out of the bay.

- Handling – Observe ESD protection; do not touch conformal-coated areas or test points unnecessarily.

- Wiring – Seat the board fully into the backplane; tighten front-panel retention screws evenly; verify keyed connectors are aligned before power-up.

- Safety – Isolate 24 VDC auxiliary and lock out the traction system before removal or insertion; follow depot LOTO procedures.

- Routine checks – Periodically inspect connectors for oxidation, clean with approved contact cleaner, and review converter self-diagnostic logs.

- Firmware pairing – In many cases, control and driver boards must run matching firmware; we can pre-check or arrange updating if required.

Quality & Certifications

- Designed for railway environments aligned with EN 50155 and EN 50121-3-2 practices

- CE marking where applicable; produced under ISO 9001 quality systems

- RoHS compliance or permitted railway exemptions, depending on build date and revision

- Warranty: 365 days from delivery

If you can share your converter serial number, rack position, and the exact silk-screen/EPROM labels on your existing boards, we’ll confirm interchangeability and ship the correct N897092520B–N897092057Y pairing without delay.

Reviews

There are no reviews yet.